Straight-toothed hole pin type hydraulic automatic limited slip differential

A technology of limited-slip differential and straight-tooth hole-pin type, which is applied in the direction of differential transmission, transmission, belt/chain/gear, etc., can solve the problems of complex structure, easy to be locked, high manufacturing cost, etc., and achieve Effects of low mounting accuracy, reduced dependency, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

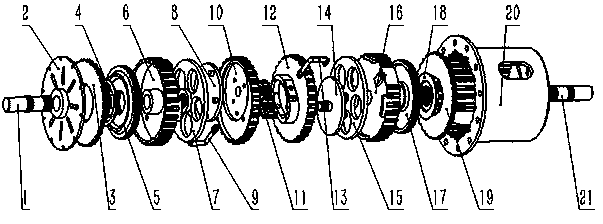

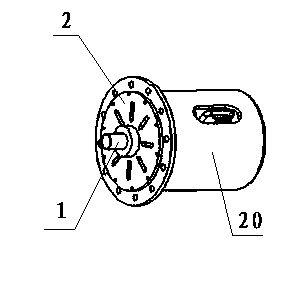

[0020] see figure 1 and image 3 , a straight hole pin type hydraulic automatic limited-slip differential, comprising a differential case 20, a left half shaft 1, a right half shaft 21, a differential mechanism and a hydraulic limited-slip mechanism, wherein,

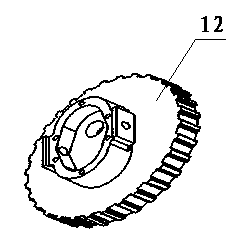

[0021] The differential mechanism comprises a left drive shell 10, a right drive shell 12, a left turntable 7, a right turntable 15, a left pin plate 8, a right pin plate 14 and two planetary gears 11, wherein the left drive shell 10 and the right drive shell 12 is installed in the differential case 20, and the left drive case 10 and the right drive case 12 cooperate with the inner splines of the differential case 20 through external splines; The circular groove that the left pin plate 8 cooperates, and the left pin plate 8 is embedded in this groove; There is a circular groove that deviates from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com