Laser scattering-based optical-fiber prefabricated rod defect detection method

An optical fiber preform and laser scattering technology, applied in the field of optical detection, can solve the problems of low detection efficiency, reliability and consistency of detection results, etc., and achieve the effect of high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

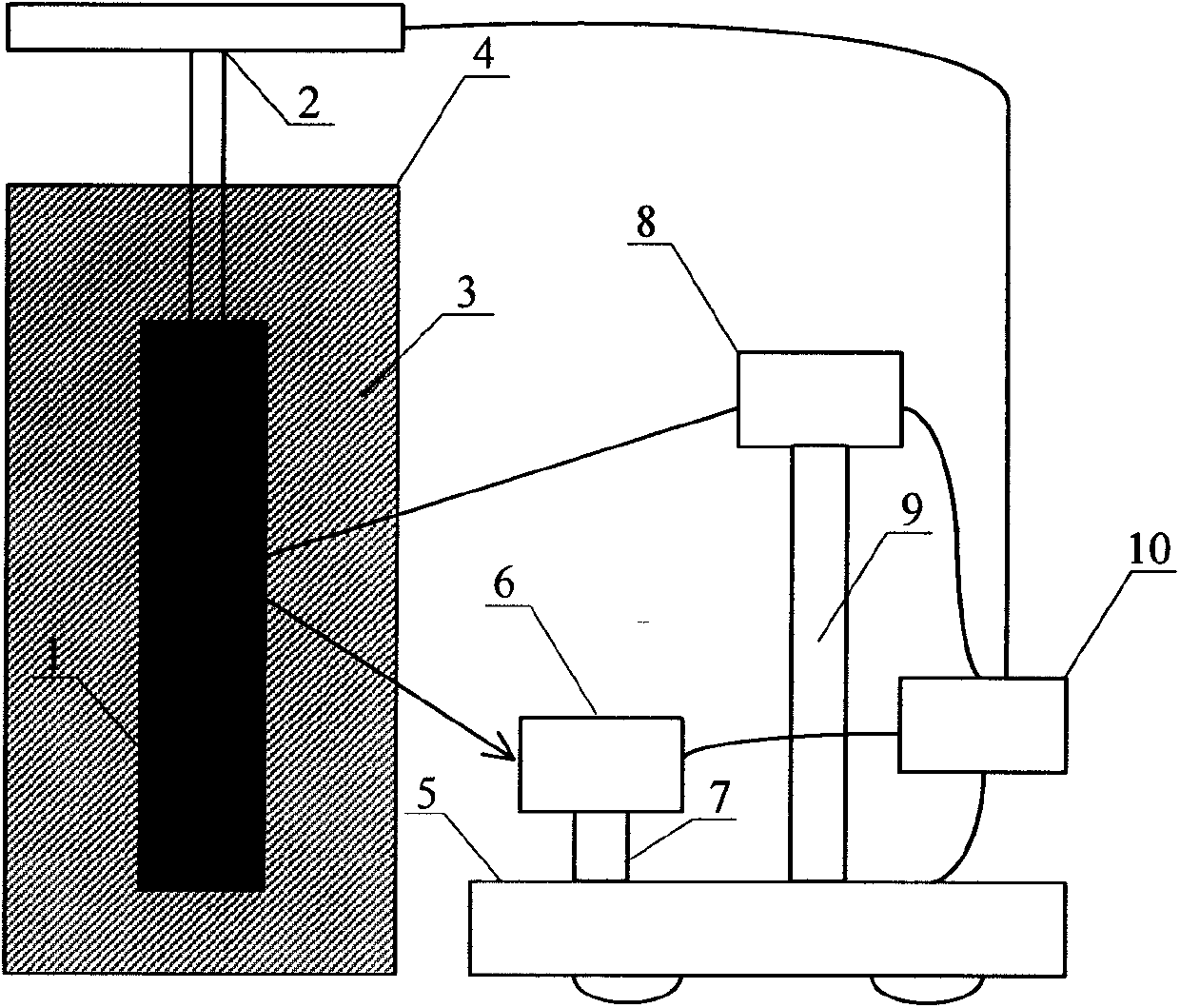

[0014] Such as figure 1 As shown, the optical fiber preform defect detection device based on laser scattering includes an optical fiber preform to be tested 1, a one-dimensional lifting device 2, a matching liquid 3, a rectangular container 4, a two-dimensional translation stage 5, a camera 6, a connecting camera and a two-dimensional The bracket 7 of the translation platform, the laser 8 outputting the linear beam, the bracket 9 connecting the laser and the two-dimensional translation platform, and the computer 10 . The optical fiber preform 1 to be tested is fixed on the one-dimensional lifting device 2; the optical fiber preform 1 to be tested is completely immersed in the matching liquid 3; the matching liquid 3 is installed in the rectangular container 4; the camera 6 is fixed on the two-dimensional translation platform through the bracket 7 5; the laser 8 output by the linear beam is fixed on the two-dimensional translation platform 5 through the bracket 9; the linear be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com