Novel withstand voltage insulation testing device for crystalline silicon photovoltaic module

A technology of withstand voltage insulation and photovoltaic modules, which is applied in the direction of testing dielectric strength, etc., and can solve problems such as damage to aluminum frames and connecting wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

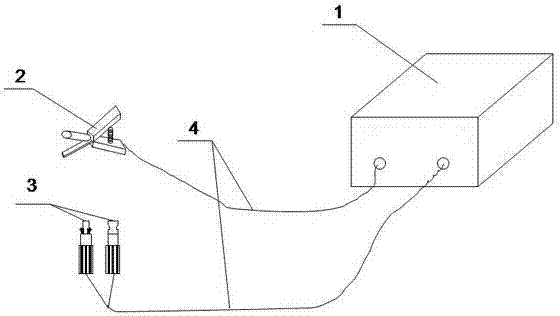

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. The invention includes a voltage withstand insulation tester 1, a fixture 2, a connector matching plug 3 and a connecting wire 4, and is characterized in that: the fixture 2 adopts a combination of a cylindrical chuck and a plate-shaped chuck, and is connected through the connecting wire 4. To the negative end of the withstand voltage insulation tester 1, the connector matching plug 3 adopts a double plug that matches the positive and negative terminals of the component wiring, and is connected to the positive end of the withstand voltage insulation tester 1 through the connecting wire 4; The diameter of the cylindrical chuck of the fixture 2 is equal to the diameter of the grounding hole and the leakage hole of the photovoltaic module; the present invention improves the positive alligator fixture of the withstand voltage insulation tester 1 into a connector matching plug 3, and improves the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com