Fire-resistant rail communication flexible cable

A flexible cable and fire-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of poor flame retardant and fire-resistant performance, poor bending performance, and easy breakage of the end of the cable, so as to achieve the softness of the cable and improve the flexibility. , Improve the effect of long-term working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

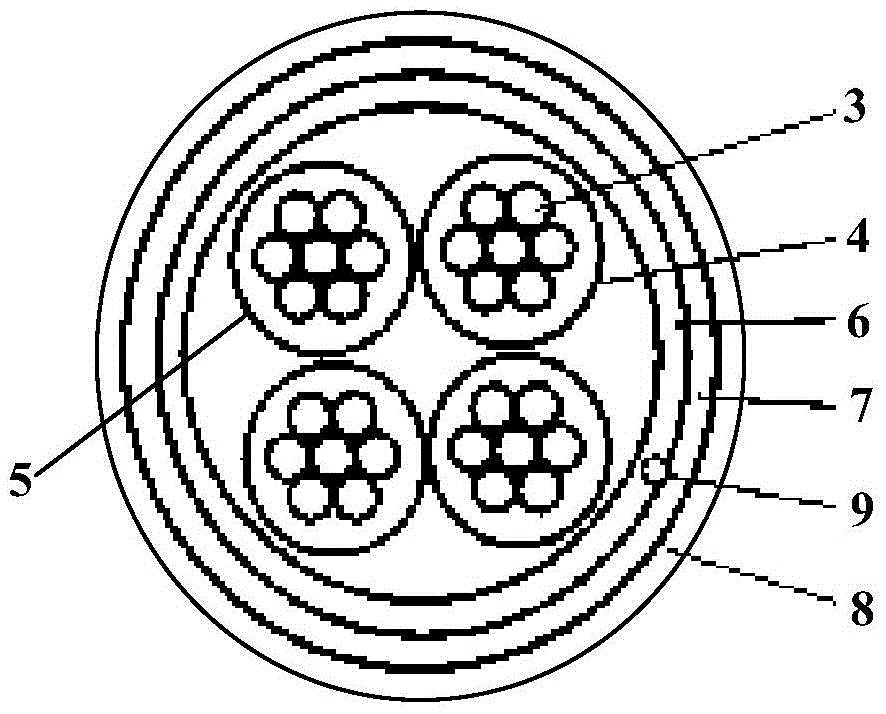

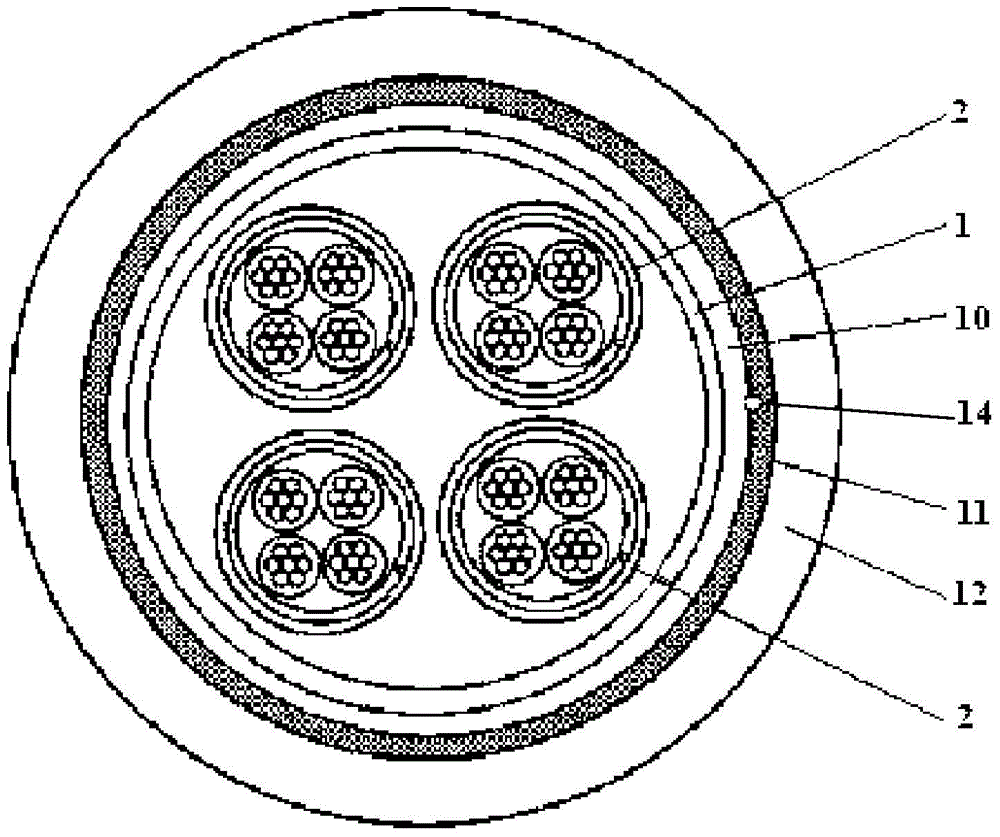

[0030] Embodiment: A fire-resistant rail communication flexible cable, including three shielded wire groups 2 wrapped by a first polyester tape 1, and the shielded wire group 2 includes two first tinned copper wires 3 made of seven In the stranded single wire 4 formed by twisting, one of the 7 first tinned copper wires 3 is located at the center, and the other 6 first tinned copper wires are stranded at the central position. The surface of the first tinned copper wire;

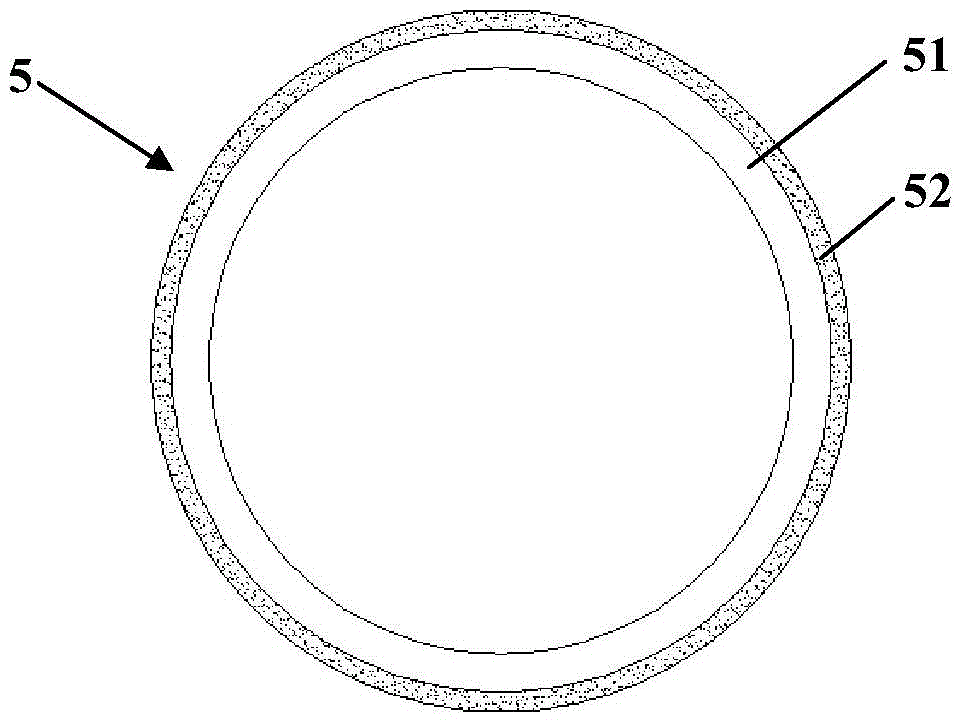

[0031] The outer surface of the twisted single wire 4 has a single wire insulation layer 5;

[0032] The two twisted single wires 4 are wrapped by a second polyester tape 6, the outer surface of the second polyester tape 6 is covered with a wire group shielding layer 7, and a wire group isolation layer 8 is wrapped on the wire group shielding layer 7 the outer surface; the first-line group drain line 9 is located between the second polyester tape 6 and the line-group shielding layer 7;

[0033] A cable fire-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap