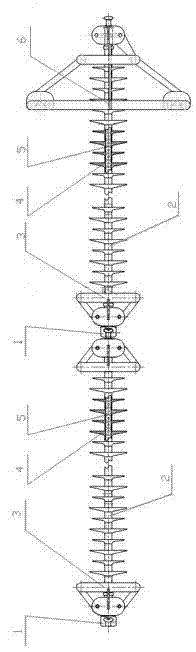

1,200kV extra-high voltage suspension type composite rod insulator

A composite insulator, UHV rod technology, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of too many connection nodes, electromechanical stress failure, uneven electric field distribution, etc. The effect of good hydrophobicity and migration, high pollution flashover voltage and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Such as figure 1 As shown, the present invention is composed of two insulators connected in series by connecting fittings 1, and the connecting fittings 1 are respectively arranged at both ends of each insulator, and the highest voltage level of the insulators is 1200kV. Each insulator includes a mandrel 2, a sheath 5 and an umbrella skirt 4 sleeved on the mandrel 2, and the two ends of the mandrel 2 are provided with a voltage equalizing ring 3, which can improve the problem of extremely uneven electric field distribution of the entire insulator. The adverse effect caused by too many connection nodes of the porcelain glass insulator is avoided. The mandrel 2 is located on the wire side. The equalizing ring 6 adopts a double-layer equalizing ring. The diameter of the upper layer of the double-layer equalizing ring is 900mm, and the diameter of the lower layer is 350mm. It can equalize step by step and effectively improve the electric field distribution. The shed 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com