Isolating switch moving contact group capable of improving contact stability

A technology of isolating switches and moving contacts, applied in the direction of contact meshing, etc., can solve problems such as high cost, high inspection requirements, fire, etc., and achieve the effects of high stability and controllability, accurate positioning, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The movable contact set for a disconnector provided by the present invention, which can improve the stability of the contacts, will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

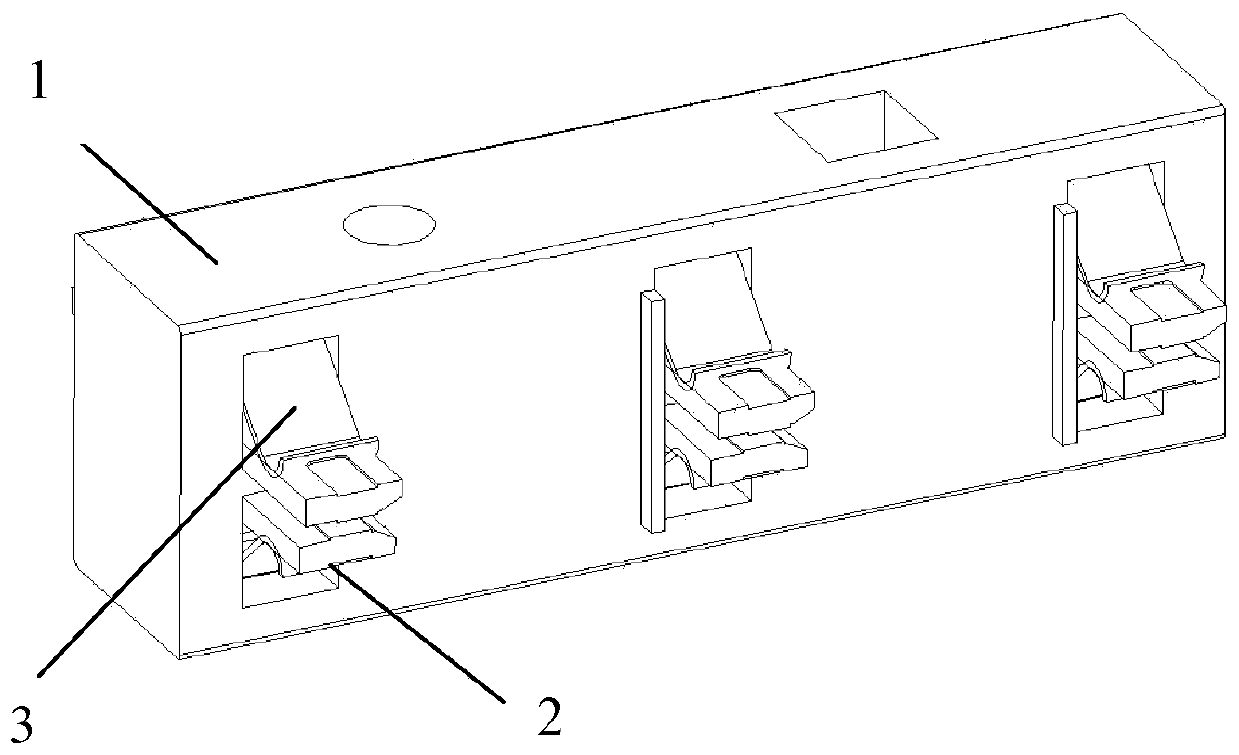

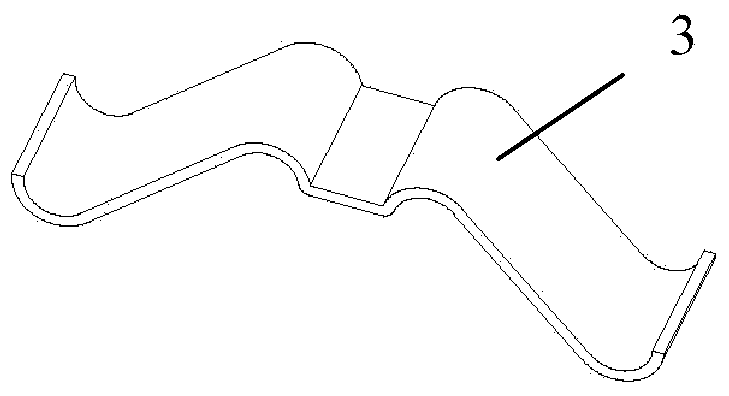

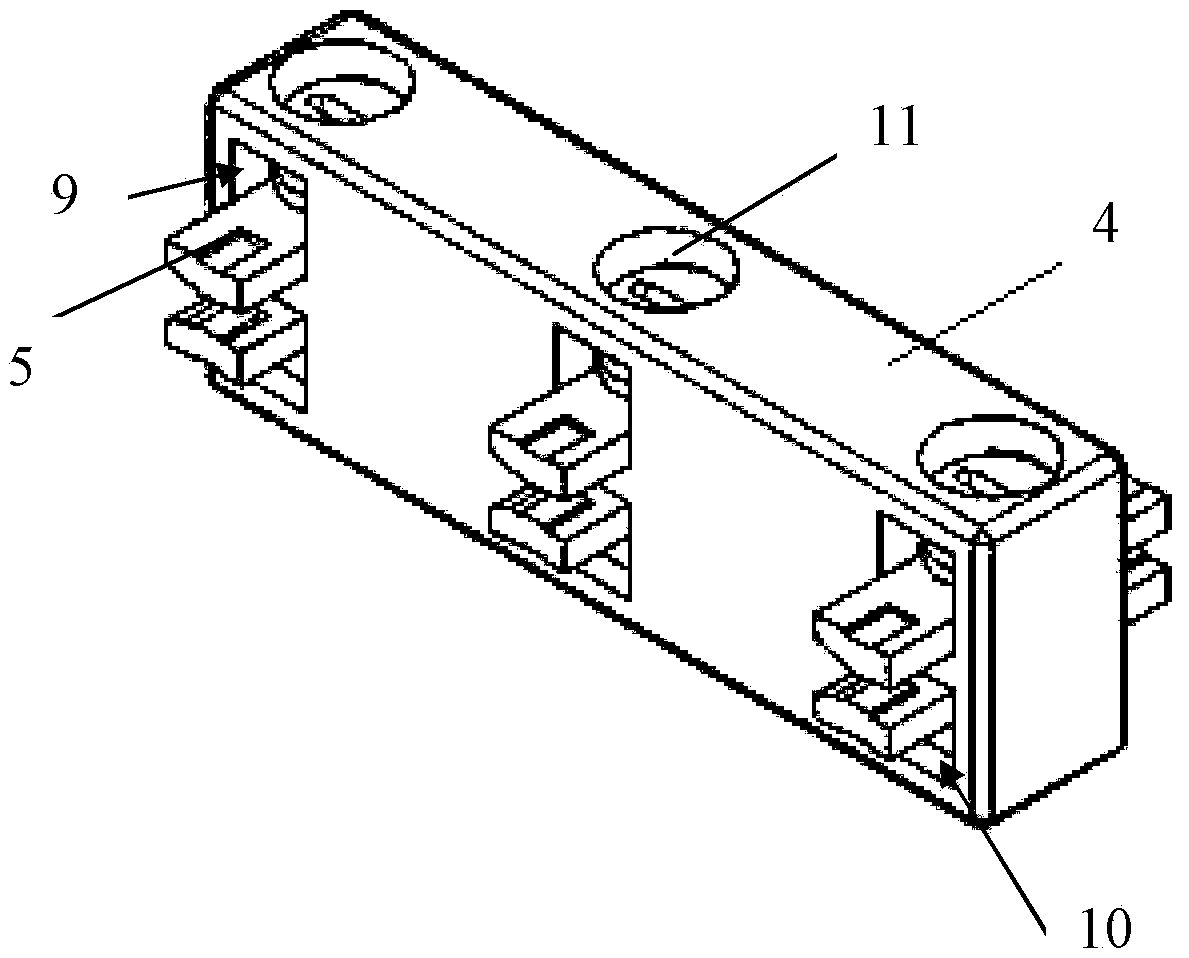

[0017] Such as image 3 — Figure 4 As shown, the moving contact set for a disconnector provided by the present invention that can improve the stability of the contacts includes a contact bracket 4, a plurality of moving contacts 5, a plurality of compression springs 6, a plurality of blocking pieces 7 and a plurality of U-shaped frame 8; wherein the middle part of the contact bracket 4 is formed through a plurality of groups of openings along the front and rear direction, and each group of openings is composed of upper and lower holes 9 and 10 arranged at intervals, and between the upper and lower holes 9 and 10 Two circular holes are formed on the partition plate, and the top and bottom surfaces of the contact bracket 4 are recessed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com