Thin sulfur hexafluoride gas density relay

A technology of sulfur hexafluoride gas and density relay, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of thick thickness, difficult to meet the application site, and thick density relay, so as to expand the scope of use and avoid false triggering Signal generator, satisfying the effect of contact hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the technical solutions of the present invention, detailed descriptions are given below through specific embodiments and in conjunction with the accompanying drawings.

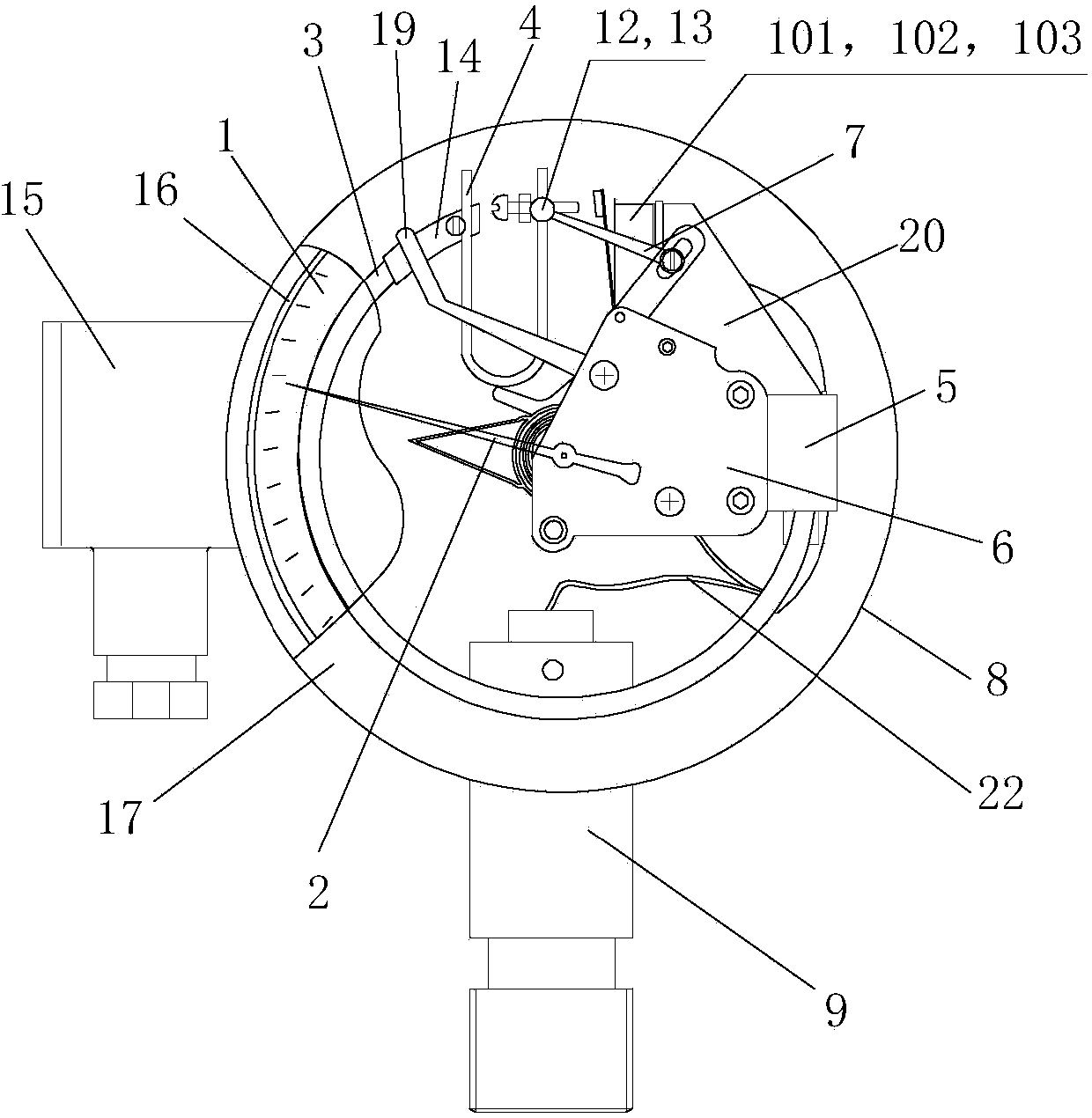

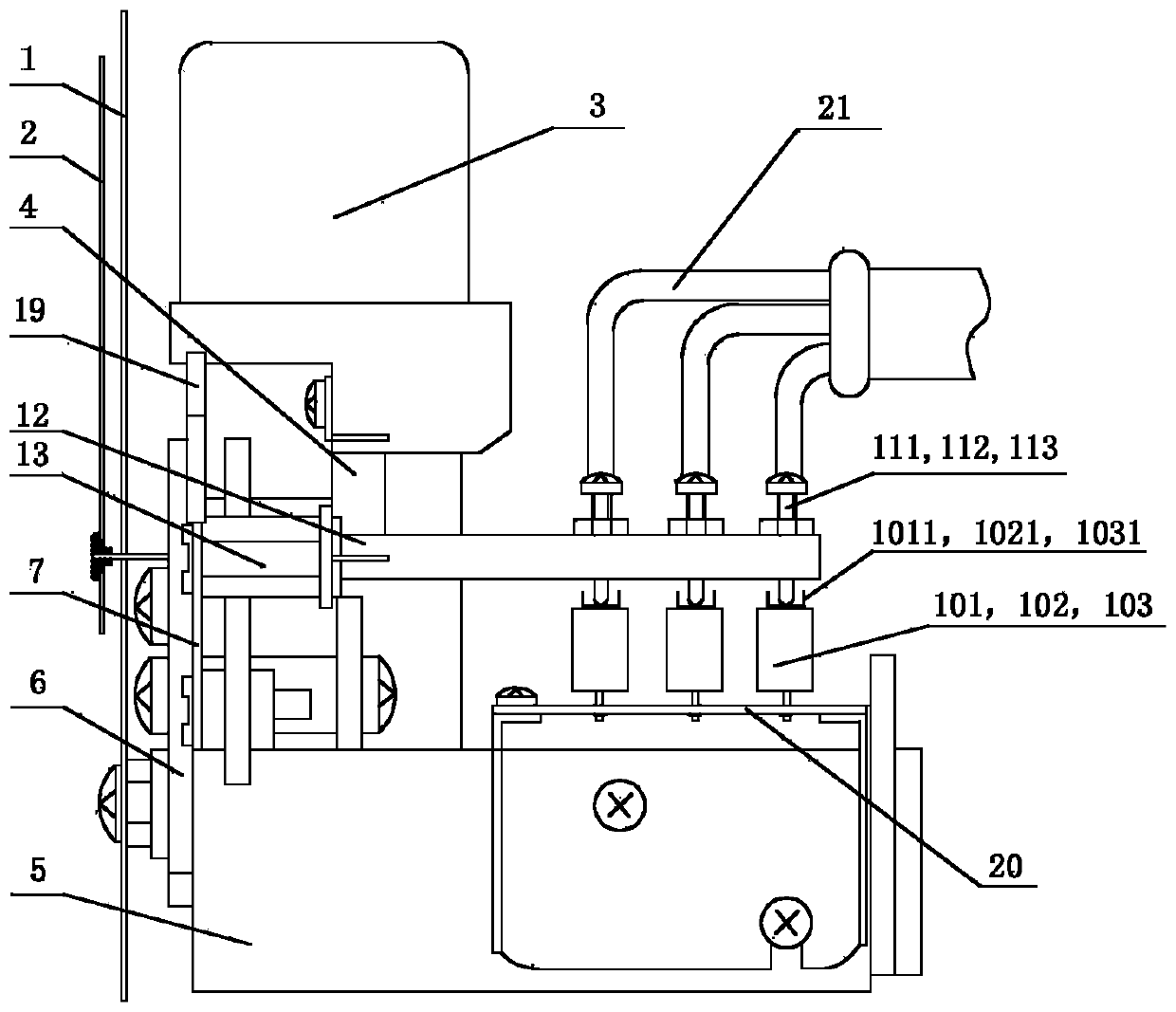

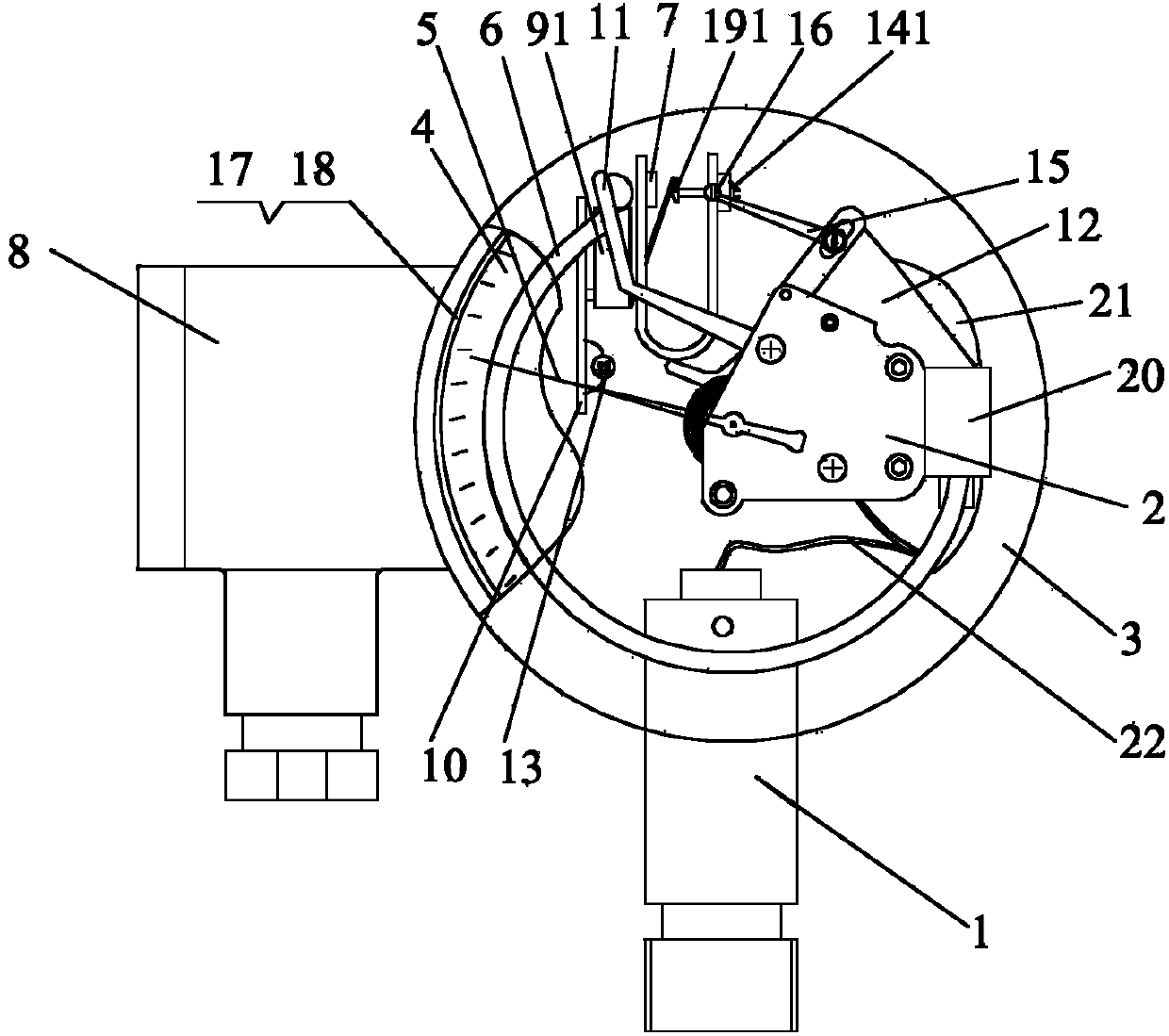

[0041] see Figure 9 to Figure 11 , the first thin sulfur hexafluoride gas density relay of the present invention is mainly composed of a joint, a core 2, a casing, a dial 4, a pointer 5, a Baden tube 6, a temperature compensation sheet 7, a wiring seat, three Micro switches 91, 92, 93, printed circuit board 10, positioning plate 11, fixing plate 12, electric wire 13, signal conditioning member 14, connecting rod 15, connecting arm 16, watch glass, cover ring, base 19, Pipe, strengthening mechanism 23, end seat 24 and other components. Among them, the joint is fixed on the shell, the core 2 is fixed on the base 19; one end of the Baden tube 6 is welded on the base 19 and communicated with it, and the other end is connected with one end of the temperature compensation sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com