AMOLED array basal plate and display device

An array substrate and array technology are applied in the field of AMOLED array substrates and display devices, and can solve the problems of reducing the aperture ratio of display devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

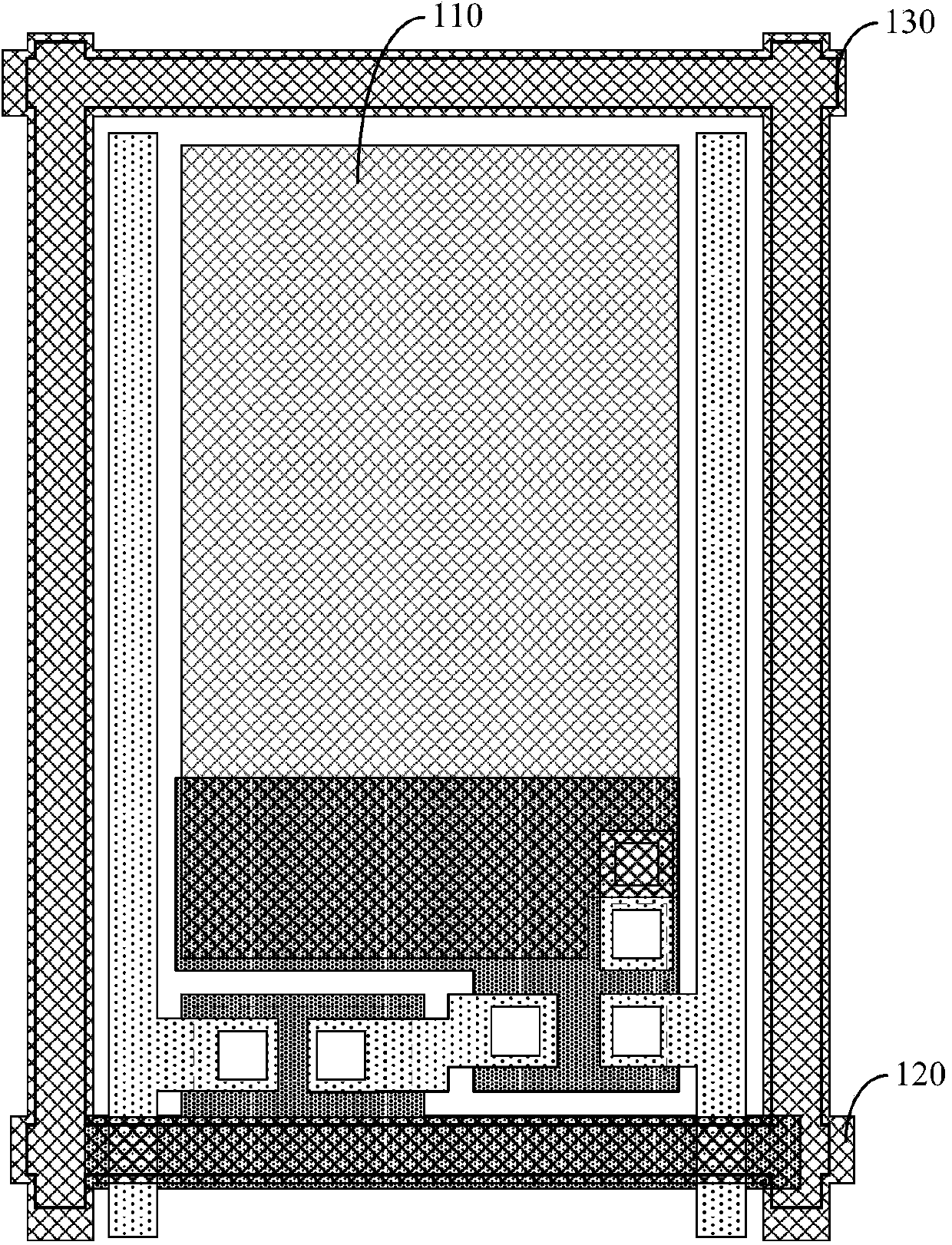

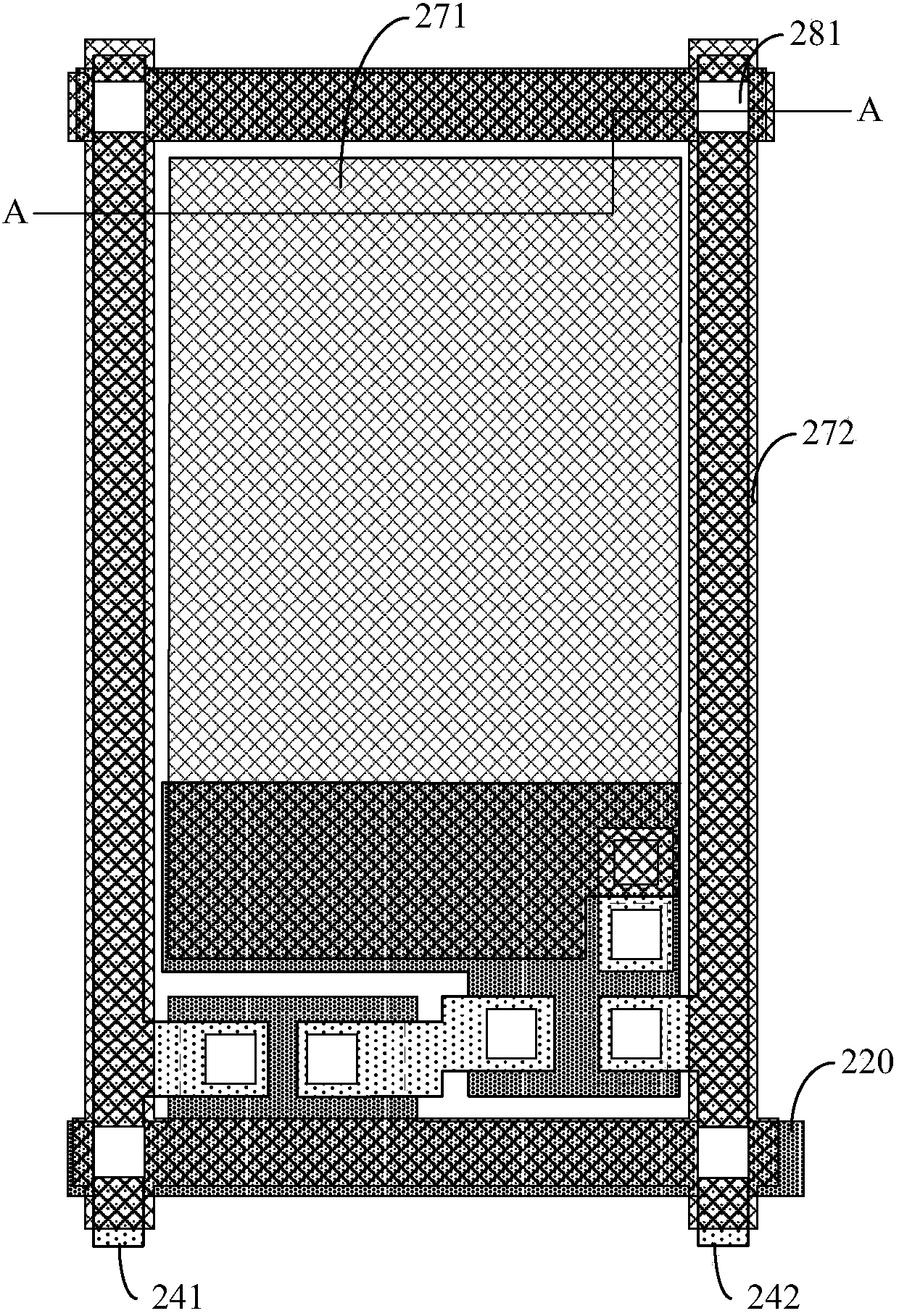

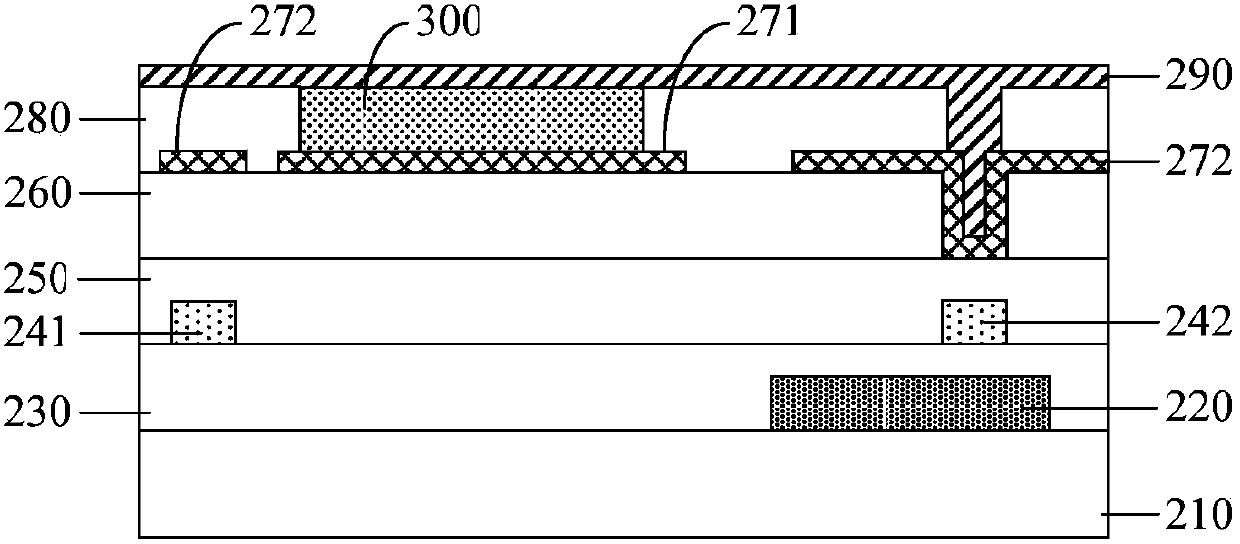

[0019] The AMOLED array substrate of the embodiment of the present invention is as figure 2 and 3 As shown, the array substrate includes several pixel structures formed in an array on the base substrate 210, and each pixel structure is surrounded by a gate line 220 and a signal line 241 and a power supply line 242 perpendicular to the gate line 220. become. Each pixel structure includes: a thin film transistor structure ( figure 2 The dotted line box in the middle), the anode 271 , the cathode 290 and the organic light-emitting layer 300 between the anode 271 and the cathode 290 . The specific hierarchy is as image 3 As shown, it includes from bottom to top: base s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com