MEMS microphone

A microphone and insulating support technology, applied in the field of microphones, can solve problems such as diaphragm rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

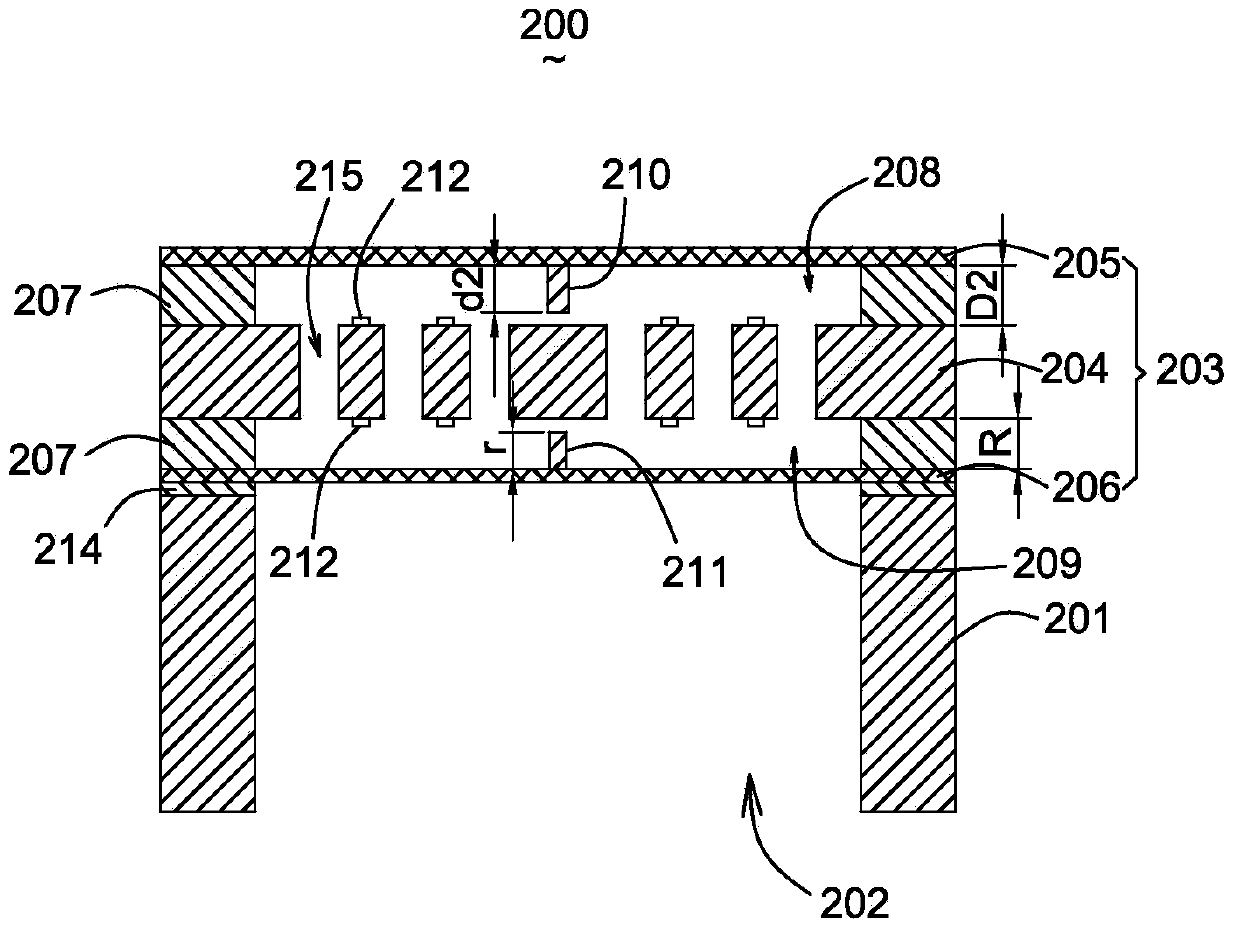

[0033] Such as figure 2 As shown, a MEMS microphone 200 includes a substrate 201 and a capacitive unit 203 disposed on the substrate 201 . The base 201 is made of semiconductor material, such as silicon, and has a through back cavity 202 , and an insulating layer 214 is disposed on the upper surface of the base 201 . The capacitor unit 203 is connected to the insulating layer 214 .

[0034] The capacitor unit 203 includes a back plate 204 , and a first diaphragm 205 and a second diaphragm 206 opposite to the back plate 204 and disposed on both sides of the back plate 204 . Insulators 207 are provided between the first diaphragm 205 and the back plate 204 and between the second diaphragm 206 and the back plate 204 . The insulating member 207 separates the first diaphragm 05 from the back plate 204 , and the second diaphragm 206 from the back plate 204 by a certain distance, and forms a first insulating gap 208 and a second insulating gap 209 respectively. A plurality of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com