High grain-unloading structure of harvester

A harvester, high-level technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., to achieve the effect of raising the grain outlet, easy to implement, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

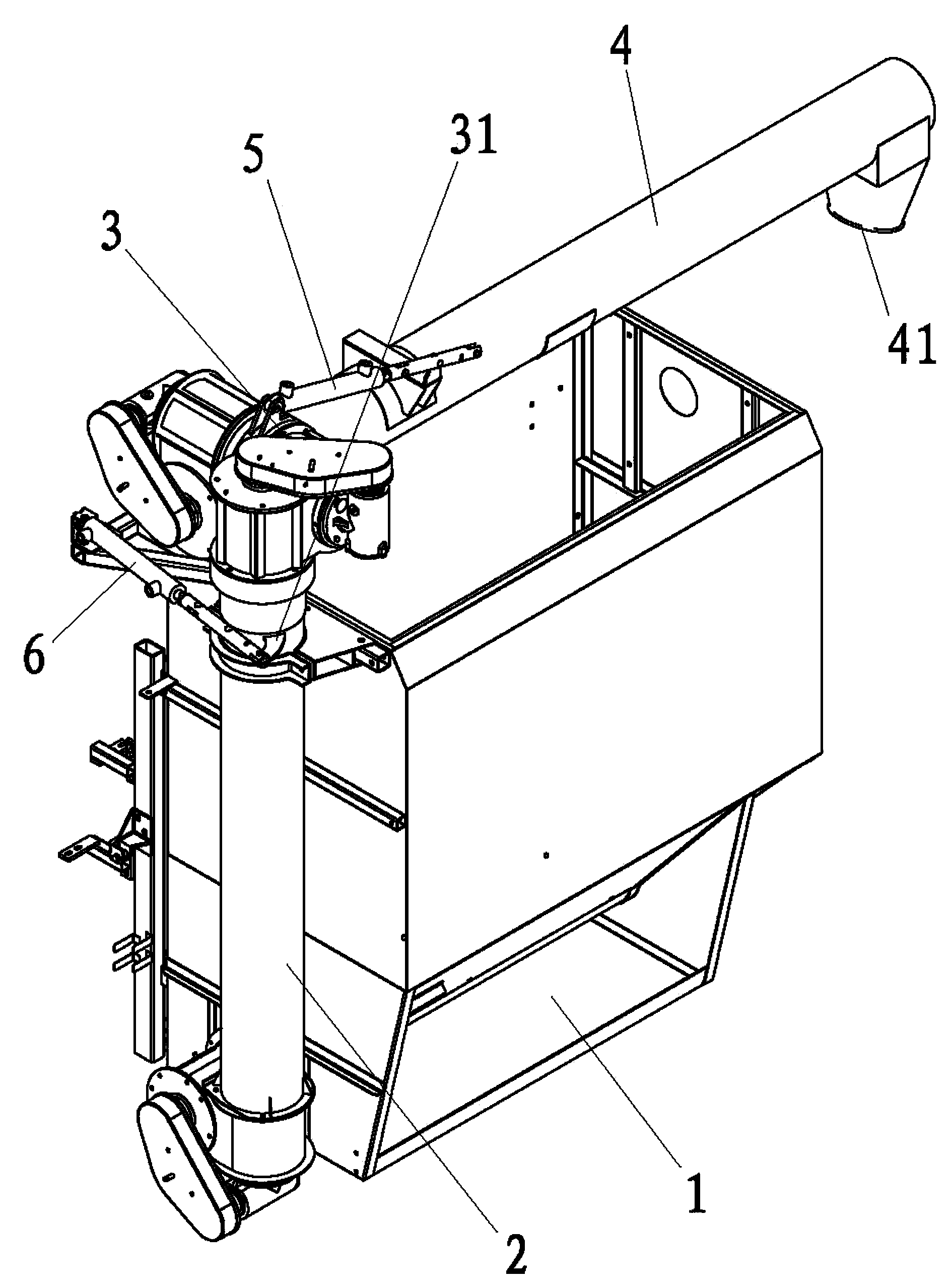

[0013] Embodiment: a kind of harvester high-position grain unloading structure, such as figure 1 As shown, it includes a granary 1, a longitudinal barrel 2 is fixed on one side of the granary 1, an intermediate conveying part 3 is rotatably connected to the upper end of the longitudinal barrel 2, and a side end of the intermediate conveying part 3 is rotatably connected with a The grain outlet barrel 4 of mouth 41.

[0014] A lifting oil cylinder 5 is arranged between the grain output barrel 4 and the middle delivery part 3, and the piston rod of the lift oil cylinder 5 is hinged to the grain output barrel 4 and its cylinder barrel is hinged to the middle delivery part 3; The hinged part of the middle delivery part 3 is higher than the hinged part between the lift cylinder 5 piston rod and the grain output gun barrel 4 .

[0015] A rotary oil cylinder 6 is provided between the upper part of the granary 1 and the middle conveying part 3; the middle conveying part 3 has an arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com