Steam setting machine special for gluing of cloth mould of mould cup and mould cup setting method

A steam setting and setting machine technology, applied in the direction of sewing tools, etc., can solve the problems of low economic benefits, high training costs, high electric heating temperature, etc., to achieve the effect of improving production efficiency, overcoming technical bottlenecks, and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

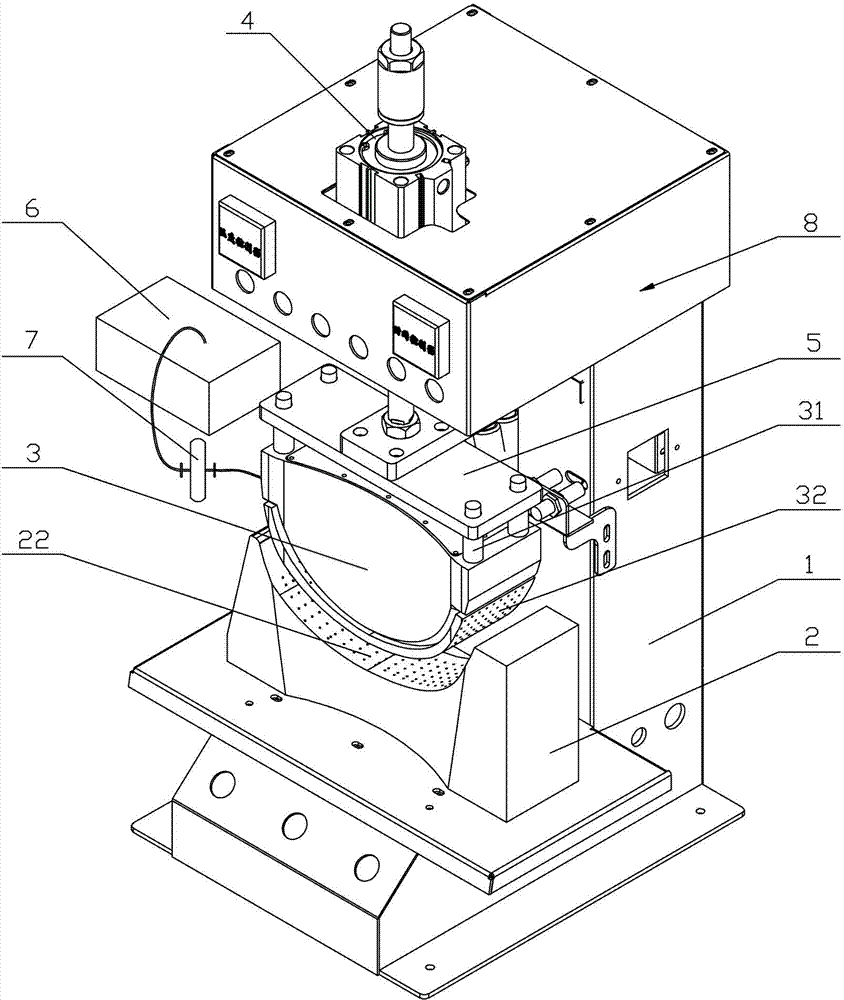

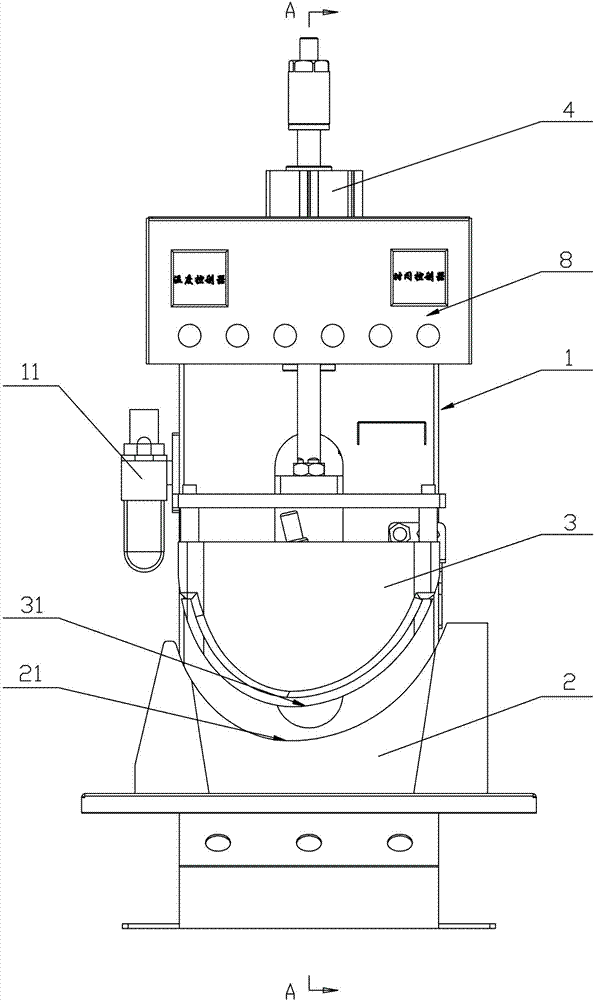

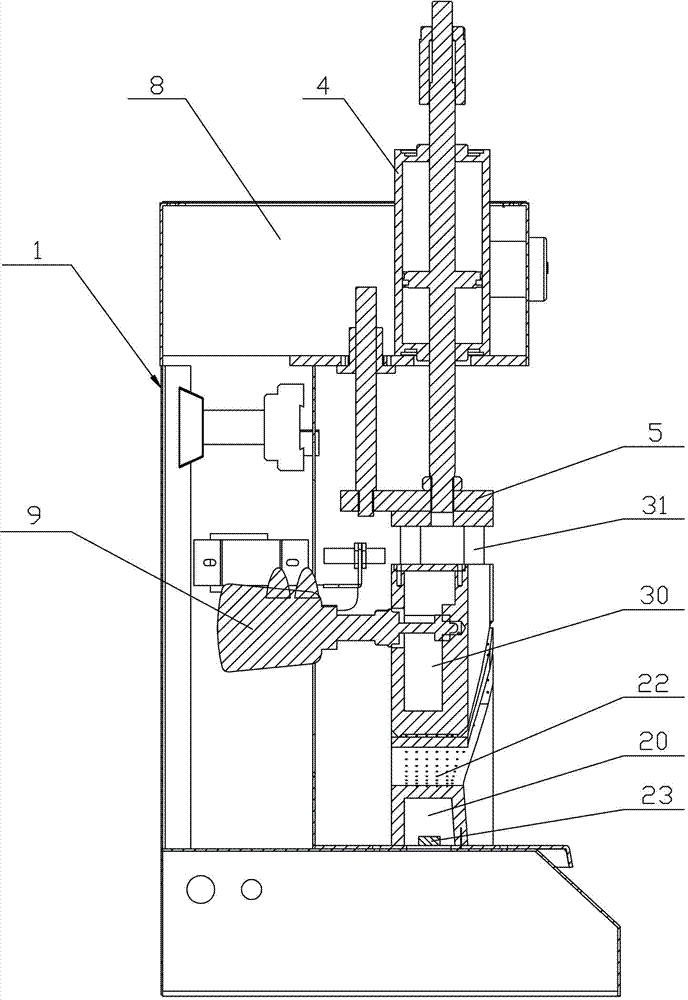

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0029] refer to figure 1 and figure 2 , a special steam setting machine for mold cup cloth mold gluing, including a support base 1, the support base 1 is roughly in the shape of "]", and the opening on the side of the support base is provided with a molding lower mold 2 and a molding upper mold from bottom to top 3. The upper end surface of the support base 1 is also provided with a cylinder 4 that drives the molding upper mold 3 to move up and down, and a connecting plate 5 is fixed above the molding upper mold 3 through a plurality of guide posts 31, and the piston rod of the cylinder 4 is fixed on the connecting plate 5 In the middle part of the end face, in order to adapt to the needs of various pressures of the upper mold 3, each guide post 31 can also be provided with a spring (not shown). An oil-water separator 11 is arranged on the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com