Casting machine vibrating device for casting special materials

A casting machine and pounding technology, applied in foundry, foundry equipment, pig iron foundry, etc., can solve the problems of unadjustable speed, unadjustable, unadjustable frequency of cast iron mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

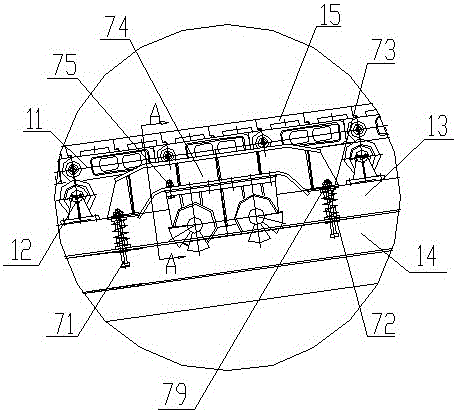

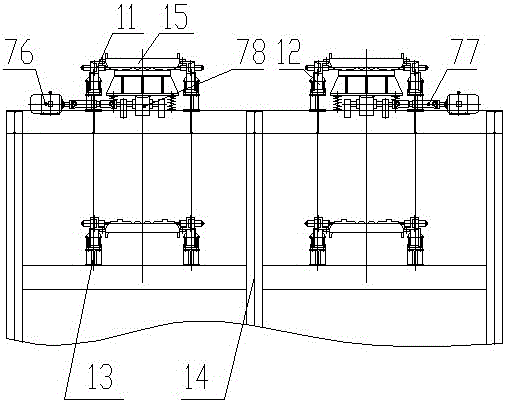

[0017] Such as figure 1 and figure 2 The shown a casting machine vibration device for casting special materials includes a vibration device 7 installed on the steel structure frame 14, and the vibration device 7 includes a vibration plate 74, the top surface of the vibration plate 74 and the The outer surface of the casting mold 15 is in contact with the bottom, and the vibrating plate 74 is arranged on the steel structure frame 14 through an elastic member. The vibrator 78 is assembled with the vibrating plate 74 through a coupling 75. The shaft device 77 is connected with the motor 76 to transmit power.

[0018] The elastic member of the present invention includes a spring 73 arranged between the vibrating plate and the steel structure frame, upper and lower supporting columns 72 are assembled at both ends of the spring 73, and the guide rod 71 passes through the vibrating plate 74, the upper and lower supporting columns in sequence 72. The spring 73 and the steel structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com