Integrated automatic microscopic welding equipment

A welding equipment and automatic spot welding technology, applied in welding equipment, resistance welding equipment, welding power sources, etc., can solve the problems of independent adjustment, the overall weight of the machine head, the accuracy of electrode force cannot meet the requirements of spot welding, etc., to achieve accurate electrode force The effect of improving output and spot welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

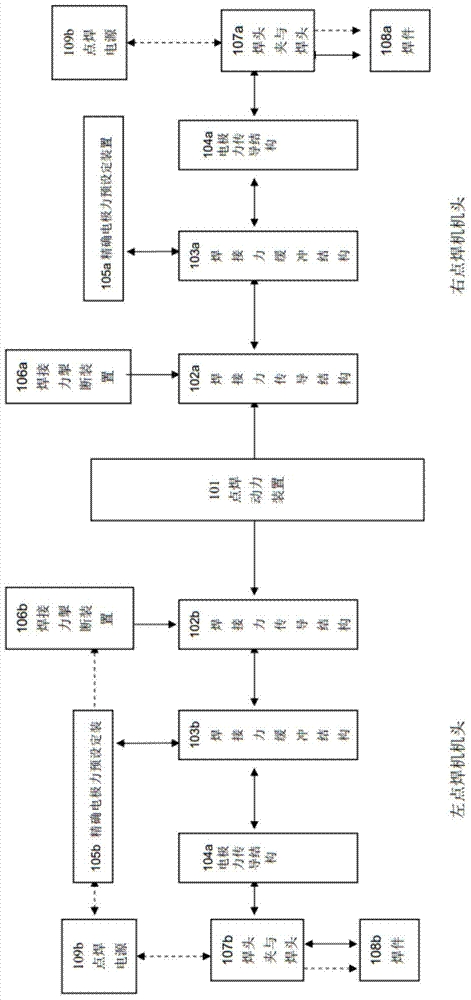

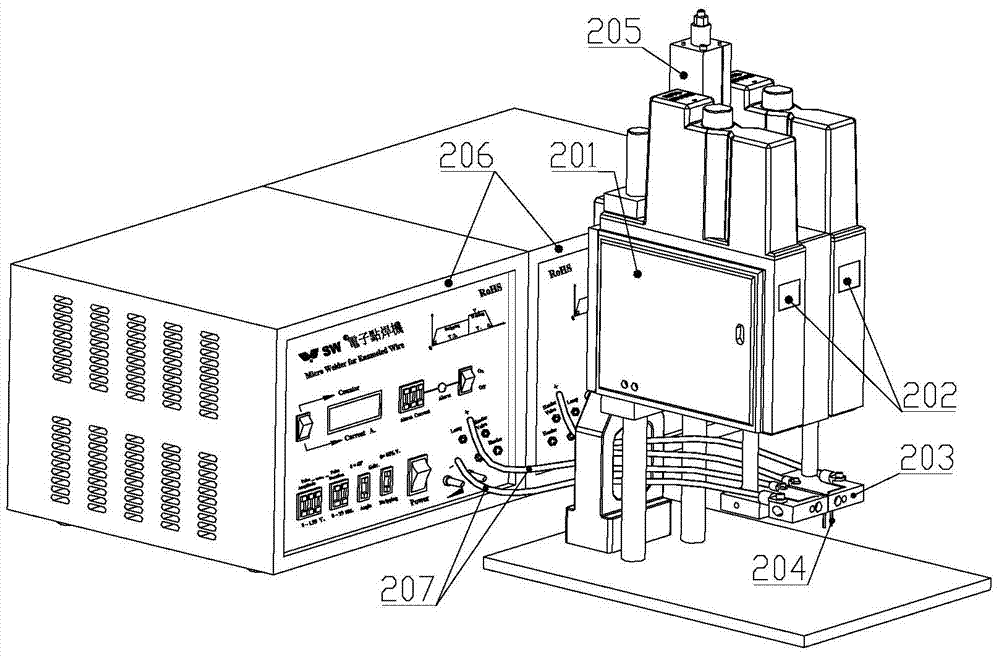

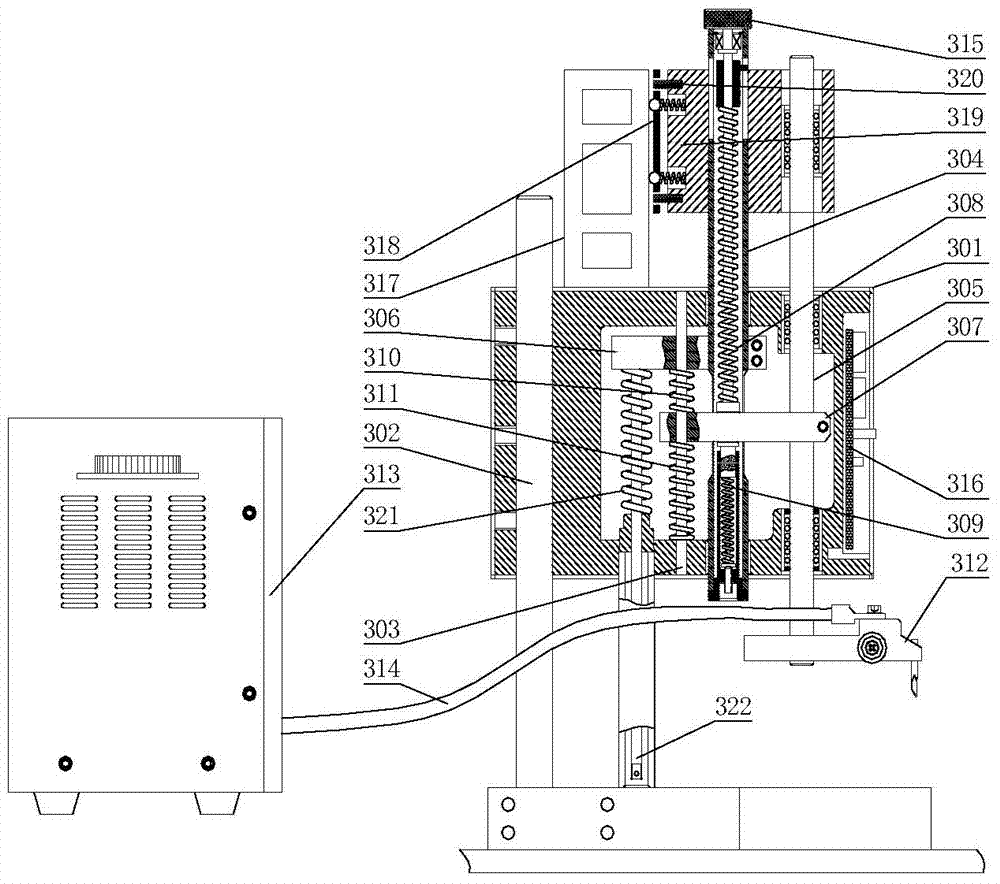

[0040] From the overall structure, the present invention can be divided into four parts, namely, two spot welding machine heads, two horizontal transverse clamp welding head clamps, spot welding power source and automatic spot welding power device. The spot welding power supply can be two spot welding power supplies connected to two horizontal clamp welding head clamps, or it can be connected to two horizontal clamp welding head clamps through the output end of one spot welding power supply, that is, two horizontal clamp welding head clamps. The welding head clamp can be powered by different spot welding power sources, or can be powered by the same spot welding power source. Since the spot welding power supply and the automatic spot welding power device are mastered by those skilled in the art, the present invention will not be described in detail, but will focus on the two parts of two spot welding machine heads and two horizontal clamp welding head clamps installed as a whole....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com