Point welding machine for hydraulic torque converter pump wheel shell and blades

A hydraulic torque converter and spot welding machine technology, applied in welding equipment, resistance welding equipment, resistance electrode holders, etc., can solve problems such as low efficiency and unstable solder joint quality, and achieve reduced labor intensity and better spot welding effect Good, high precision spot welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

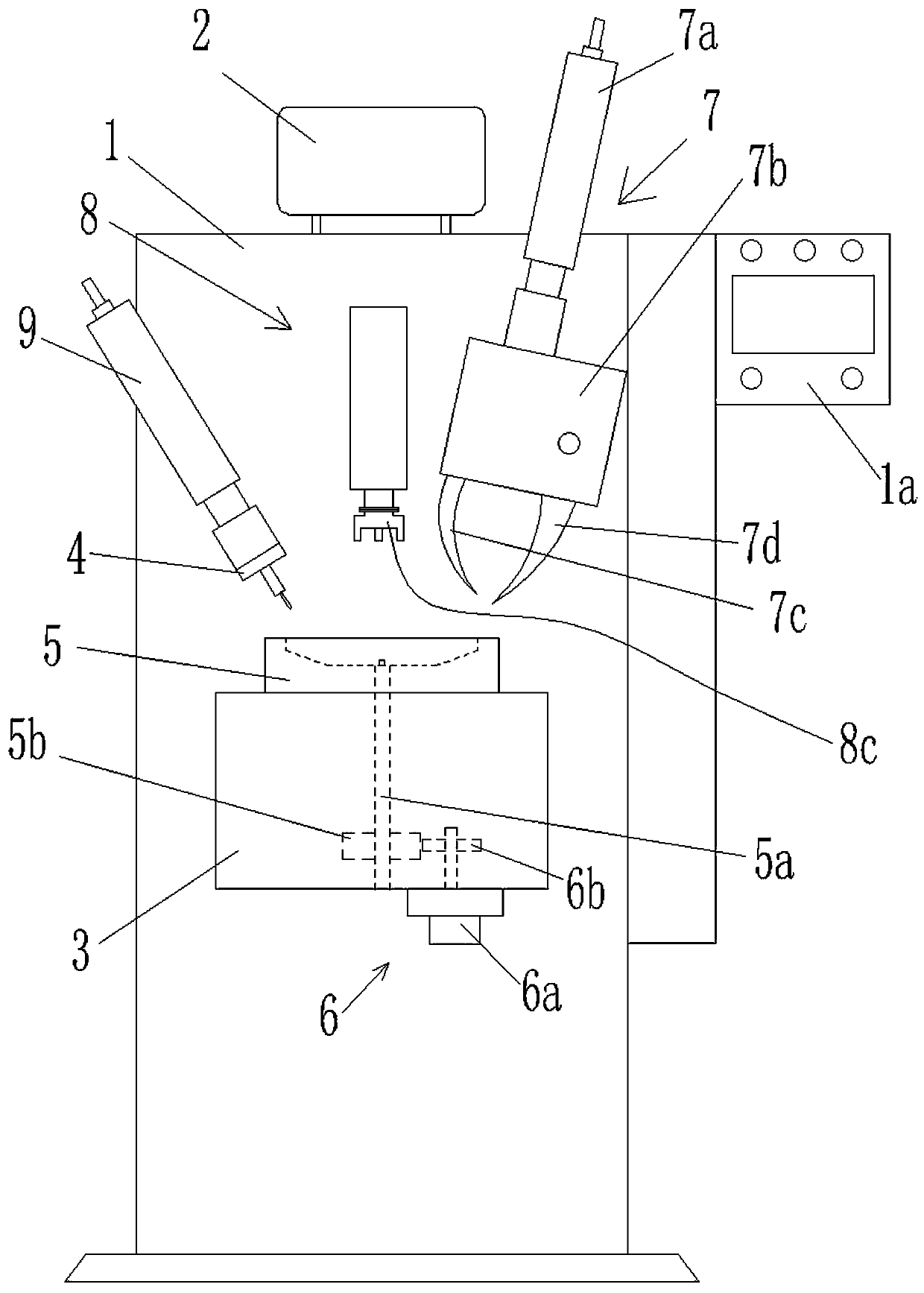

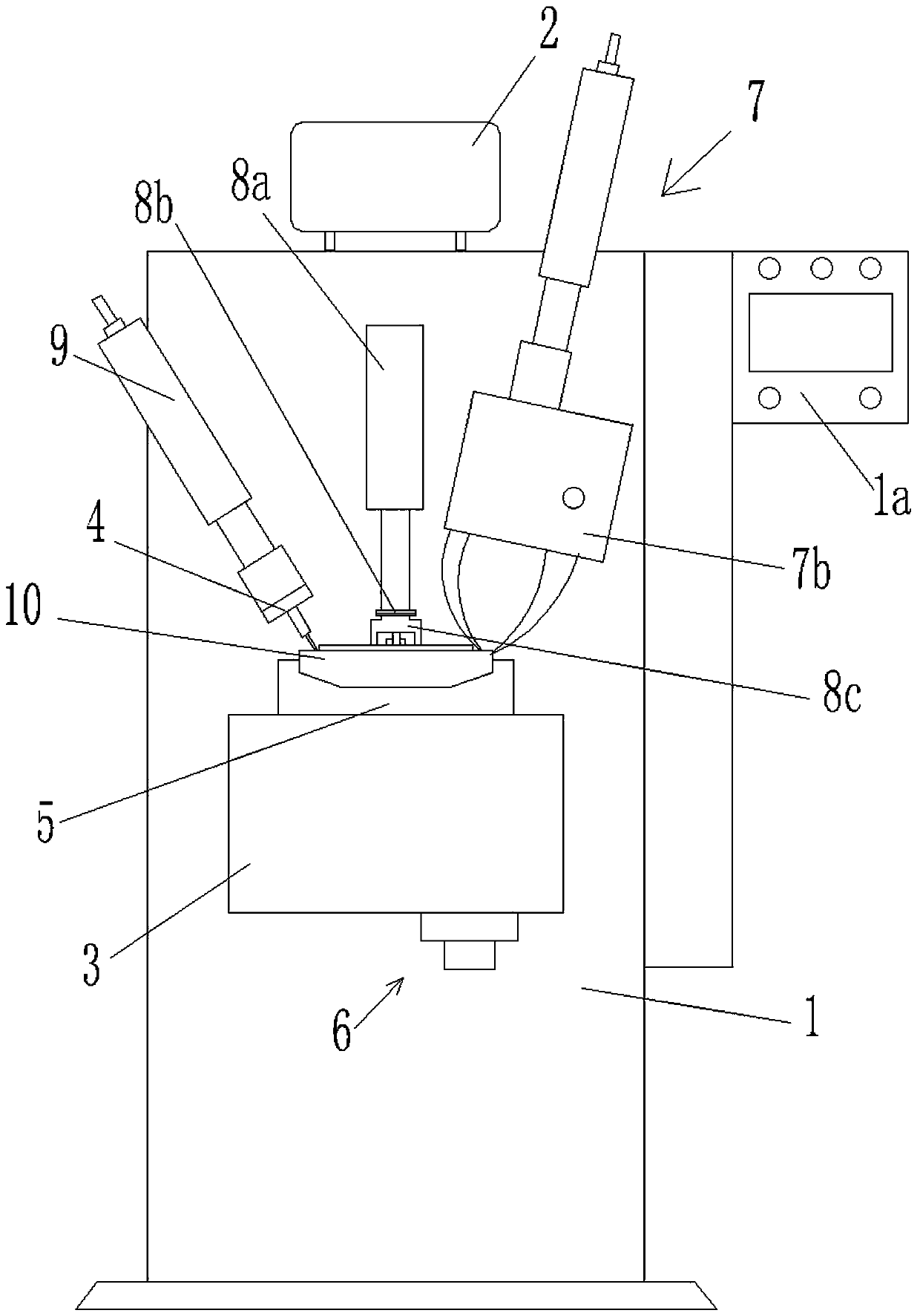

[0014] like figure 1 and 2 As shown, a spot welding machine for the pump wheel casing and blade of the hydraulic torque converter, it includes a body 1, an air source 2 is provided on the top of the body 1, a control device 1a is provided on the upper side of the body 1, and The middle part of the body 1 is provided with an electric welding station 3 protruding horizontally.

[0015] The body 1 above the electric welding station 3 is provided with the first cylinder 9 of oblique distribution, the first spot welding head 4 is provided at the telescopic rod lower end of the first cylinder 9, and the pump wheel shell 10 is provided on the electric welding station 3 Corresponding to the matching copper electrode seat 5, the first spot welding head 4 is correspondingly matched with the copper electrode seat 5.

[0016] In the electric welding station 3, there is also a rotating device 6 corresponding to the electrode holder 5. The rotating device 6 includes: a servo motor 6a, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com