Laser welding machine and operation method thereof

A laser welding machine and laser head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unreliable connection strength and fatigue resistance, affect the health of workers, and pollute the production environment. Improve welding quality, high work efficiency, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

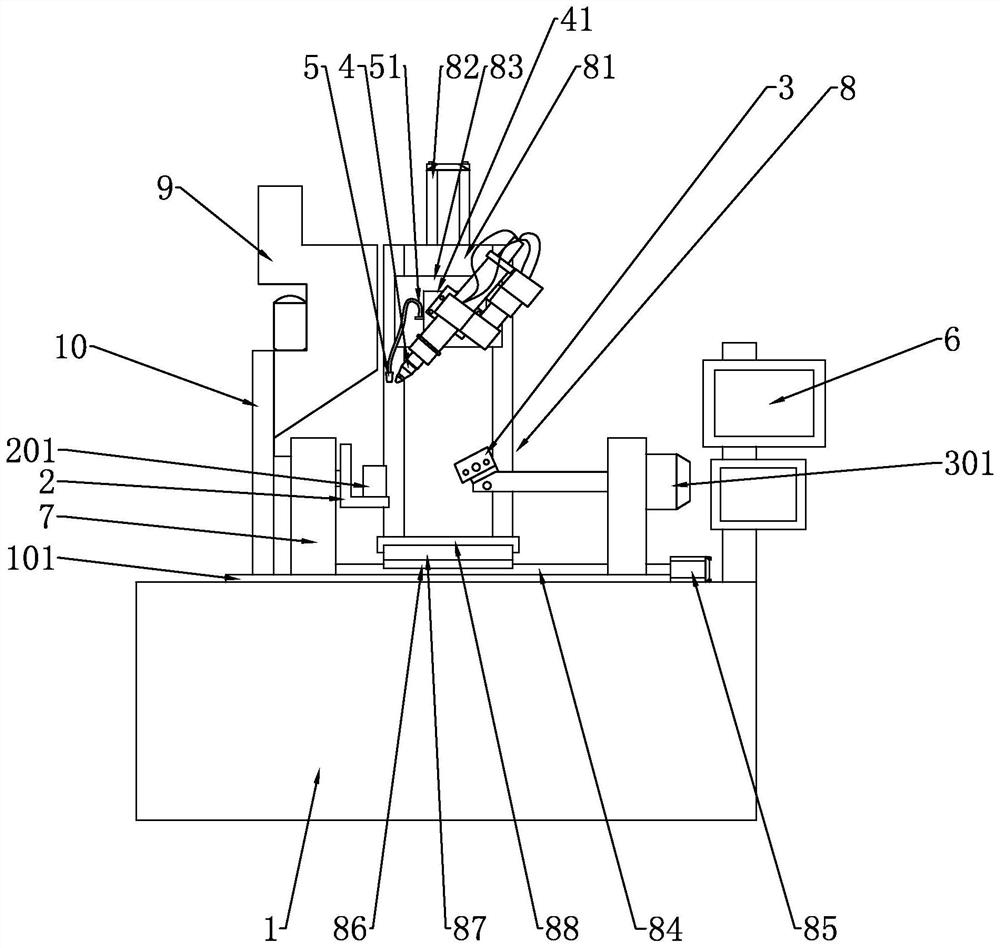

[0058] Such as Figure 1 to Figure 3 As shown, the embodiment of the present application provides a laser welding machine, which is characterized in that it includes:

[0059] A base 1, the upper surface of the base 1 is fixedly provided with a working table 101;

[0060] The left workpiece clamp 2, the sleeve rod 201 is arranged on the left workpiece clamp 2;

[0061] Right workpiece holder 3, said right workpiece holder 3 is provided with a clamping motor;

[0062] Laser head 4;

[0063] A microscopic camera 5, the surrounding of the microscopic camera 5 is provided with an illuminating lamp;

[0064] Display 6;

[0065]Wherein, the left workpiece clamp 2 and the right workpiece clamp 3 are all arranged on the left and right sides of the upper surface of the worktable 101 through the bracket 7, the left workpiece clamp 2 is connected with the bracket 7 in rotation, and the right workpiece clamp 3 is passed through the first The rotating motor 301 is rotationally connect...

Embodiment 2

[0068] In this embodiment, in addition to including the structural features of the foregoing embodiments, further said servo mechanism 8 also includes:

[0069] Z-axis support 81, the Z-axis support 81 is provided with a Z-axis driving motor 82 and a Z-axis slider 83;

[0070] X-axis support 84, the X-axis support 84 is provided with an X-axis driving motor 85 and an X-axis slider 86;

[0071] Y-axis support 87, the Y-axis support 87 is provided with a Y-axis drive motor and a Y-axis slider 88;

[0072] Wherein, the X-axis bracket 84 is fixedly arranged on the upper surface of the worktable 101, the X-axis slider 86 is slidably arranged on the X-axis bracket 84 and driven by the X-axis driving motor 85, and the Y-axis bracket 87 is fixedly arranged On the X-axis slider 86, the Y-axis slider 88 is slidably arranged on the Y-axis bracket 87 and driven by a Y-axis drive motor, and the Z-axis bracket 81 is fixedly arranged on the Y-axis slider 88, and the Z The shaft slider 83 i...

Embodiment 3

[0075] In this embodiment, in addition to including the structural features of the foregoing embodiments, it further includes:

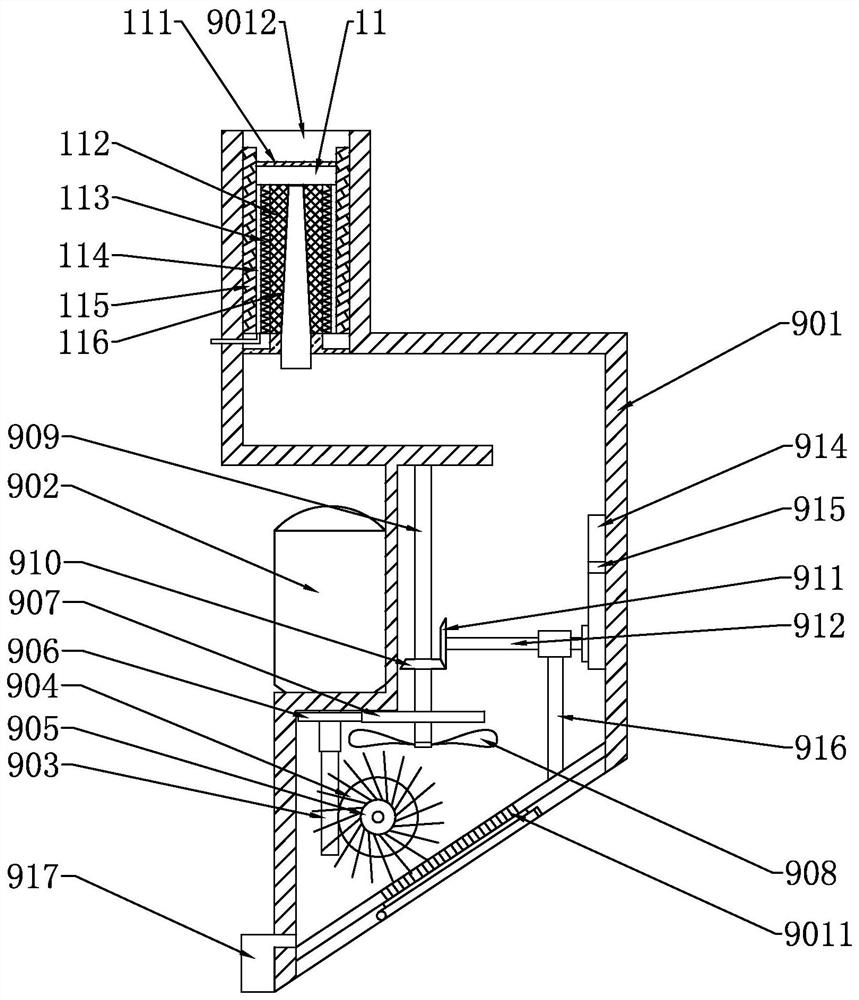

[0076] Flue gas treatment mechanism 9;

[0077] Mounting frame 10;

[0078] Wherein, the installation frame 10 is fixedly arranged on the upper surface of the working table 1, and the fume treatment mechanism 9 is fixedly arranged on the installation frame 10 and faces the welding area.

[0079] In the embodiment of the present application, the above-mentioned laser welding machine is adopted. During use, the fume processing mechanism can centrally process the fume generated during the welding process, reducing the phenomenon that the fume diffuses and pollutes the working environment, and reduces the workload. The health of personnel is damaged due to the harmful substances in the smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com