Method and mechanism for the indirect coupling torque control

A torque control, indirect technology, used in power tools, manufacturing tools, wrenches, etc., can solve the problem of not being able to respond to the locking torque in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

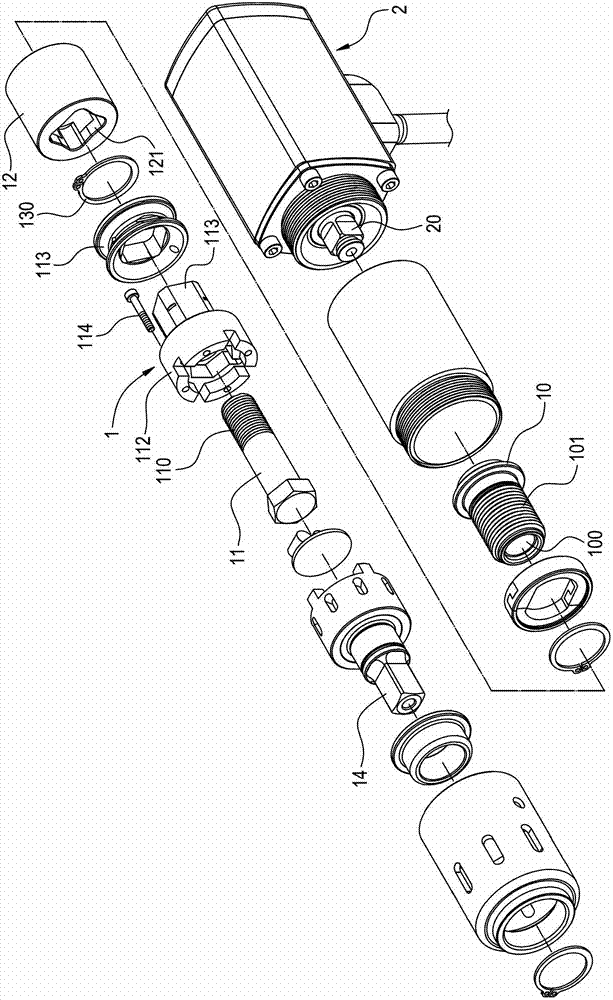

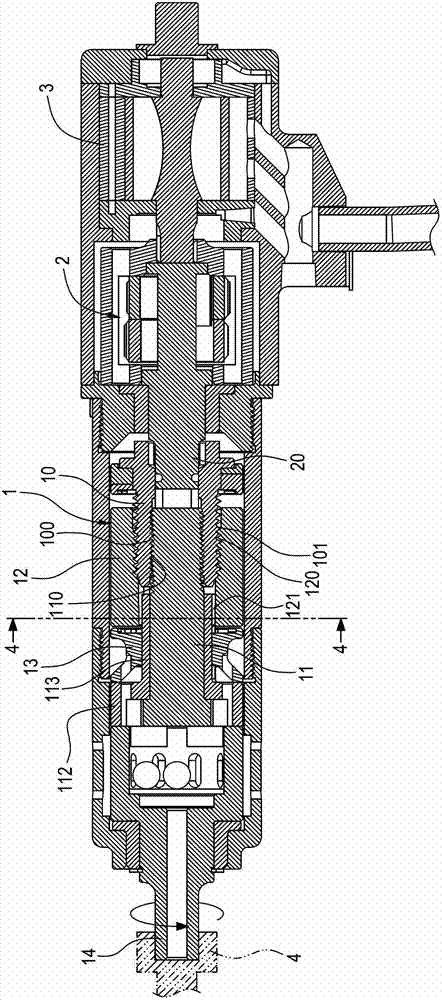

[0041] see figure 2 and image 3 , are respectively an exploded perspective view and a schematic cross-sectional view of the first embodiment of the torque control mechanism of the present invention. The present invention provides an indirect coupling torque control method and its mechanism. The torque control mechanism 1 is a screw mechanism for interlocking with a rotary percussion mechanism 2. The rotary percussion mechanism 2 is driven by a motor 3 (eg image 3 ) is driven to move, and then drives a front-end drive shaft 20 to rotate; since this part can be the basic structure of a general traditional impact power tool, it will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com