H-shaped supporting pile die with steam curing device

A technology of steam curing and supporting piles, which is applied in the direction of molds, mold auxiliary parts, manufacturing tools, etc., which can solve the long maintenance time (generally takes more than 41 hours, the mold and H-shaped supporting piles are twisted, and the production efficiency is low. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described in detail below through examples, but the present invention is not limited only to the following examples.

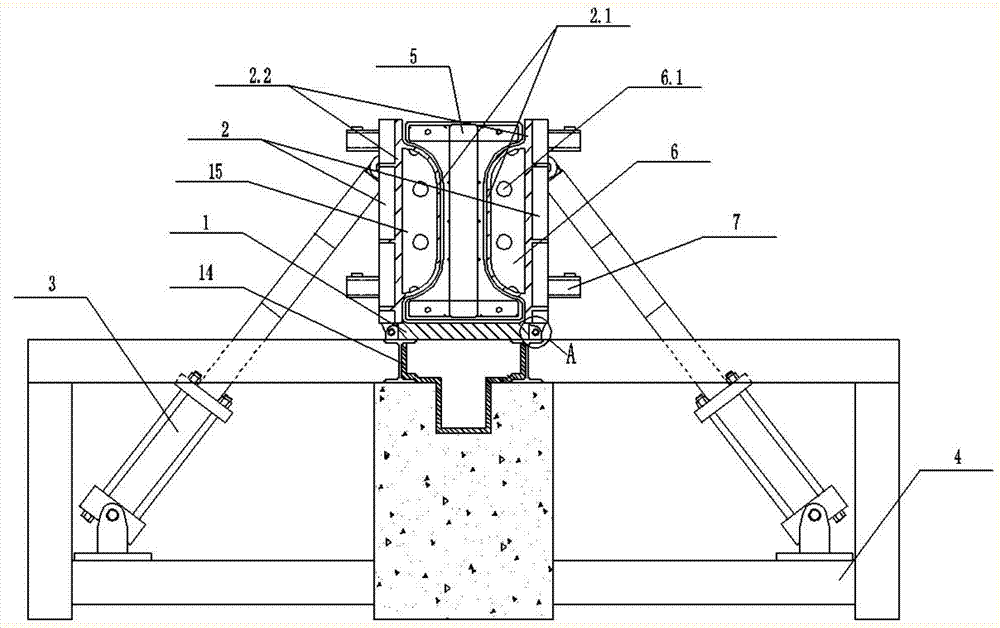

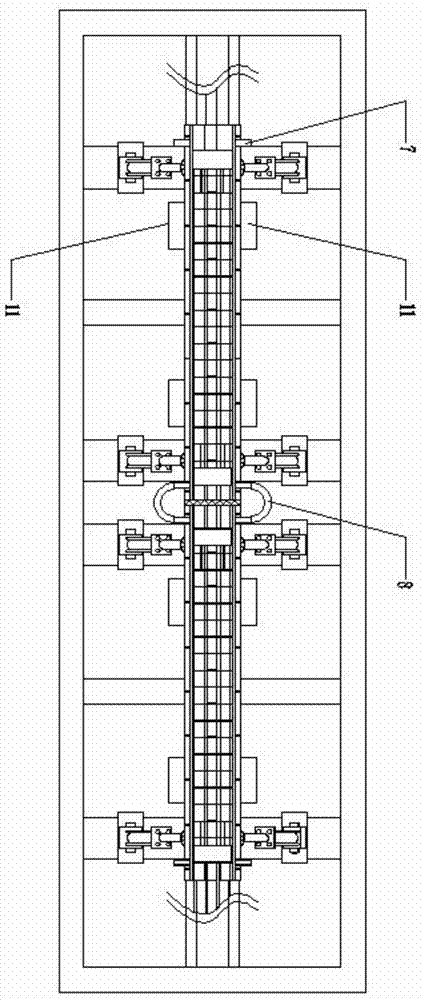

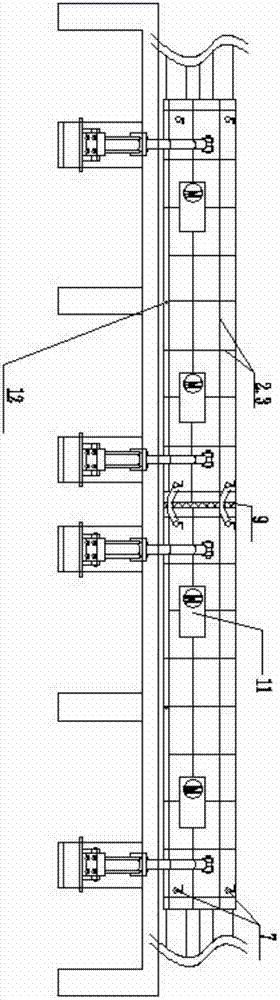

[0023] Such as Figure 1-4 As shown, a H-type support pile mold with a steam curing device of the present invention includes at least one mold unit, each mold unit includes a bottom plate 1, left and right side plates 2.2 hinged with the bottom plate 1, and the left 1. The right side plate 2.2 and the left and right cavity panels 2.1 form a hollow part 15; the oil cylinder 3 connected with the left and right side plates 2.2 fixes the base 4 of the oil cylinder 3, and the bottom end of the oil cylinder 3 is hinged with the base 4, and It is characterized in that: the hollow part 15 is provided with a number of support structures 6 for preventing the deformation of the left and right cavity panels 2.1; the support structure 6 is provided with a steam channel 6.1 for steam circulation; the mold unit The pipe 7 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com