A high-permeability film production line and its production process

A high-permeability film and production line technology, applied to other household appliances, household appliances, flat products, etc., can solve the problems of low quality parameters such as product transparency and strength, unstable strength and transparency, thickness or width deviation, etc., to achieve Improvement of cyclone separation effect, reduction of thermal expansion coefficient, and improvement of flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

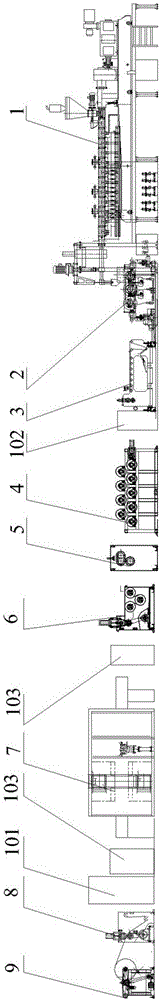

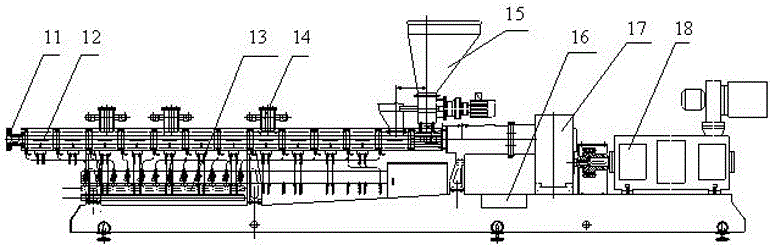

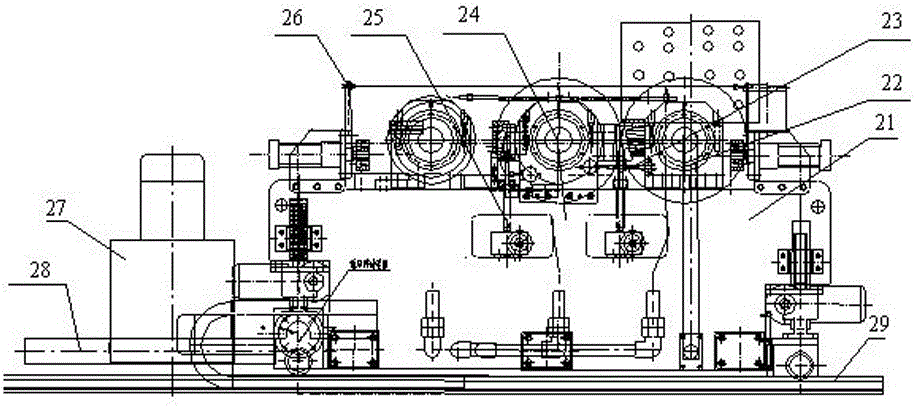

[0043] as attached Figure 11 As shown, a high-permeability film production line is used to produce high-permeability film products, including a twin-screw extruder 1, a three-roll calender 2, a tractor 3, a nine-roll preheating device 4, and a longitudinal stretching machine arranged in sequence. Machine 5, cooling tractor 6, transverse stretching machine 7, transverse stretching tractor 8, coiler 9. It also includes an online crusher 102 between the tractor 3 and the nine-roll preheating device 4, a waste edge coiler 103 between the cooling tractor 6 and the transverse stretcher 7, and a waste edge coiler 103 between the transverse stretcher 7 and the transverse stretcher 7. A waste edge coiler 103 between the pulling tractor 8, and a thickness gauge 101 located between the waste edge coiler 103 and the horizontal pulling tractor 8. The waste edge coiler 103 is used as a backup for the online crusher 102. When the online crusher 102 cannot be used, the waste edge coiler 103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com