Railway vehicle draw gear box

A rail vehicle and coupler box technology, which is applied in the direction of railway vehicle coupling accessories, railway car body parts, railway couplings, etc., can solve the problems of long distance from rescue positions, increase of coupler boxes, unfavorable installation and use, etc., and achieve reduction Small footprint, reduced height, increased height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

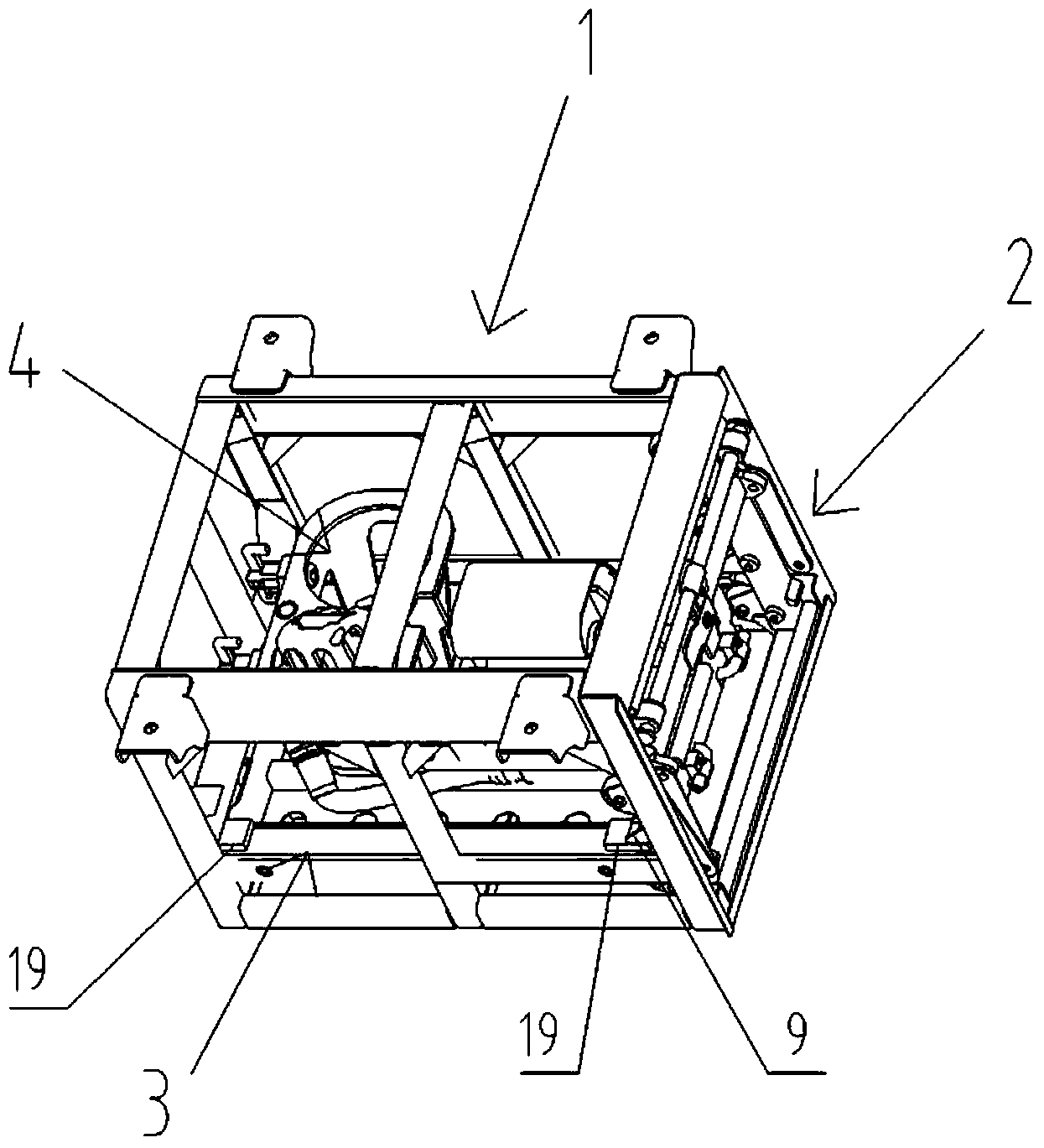

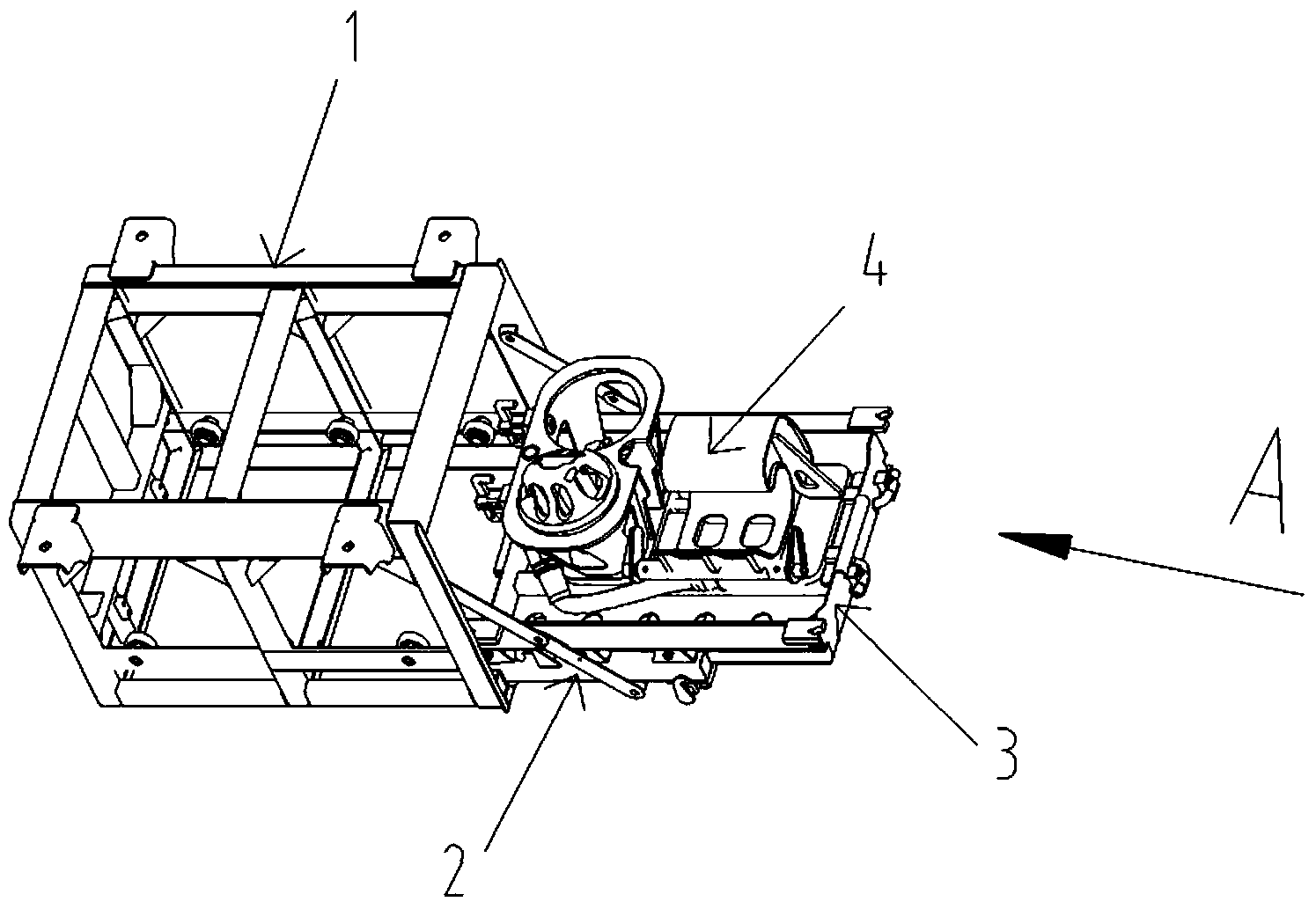

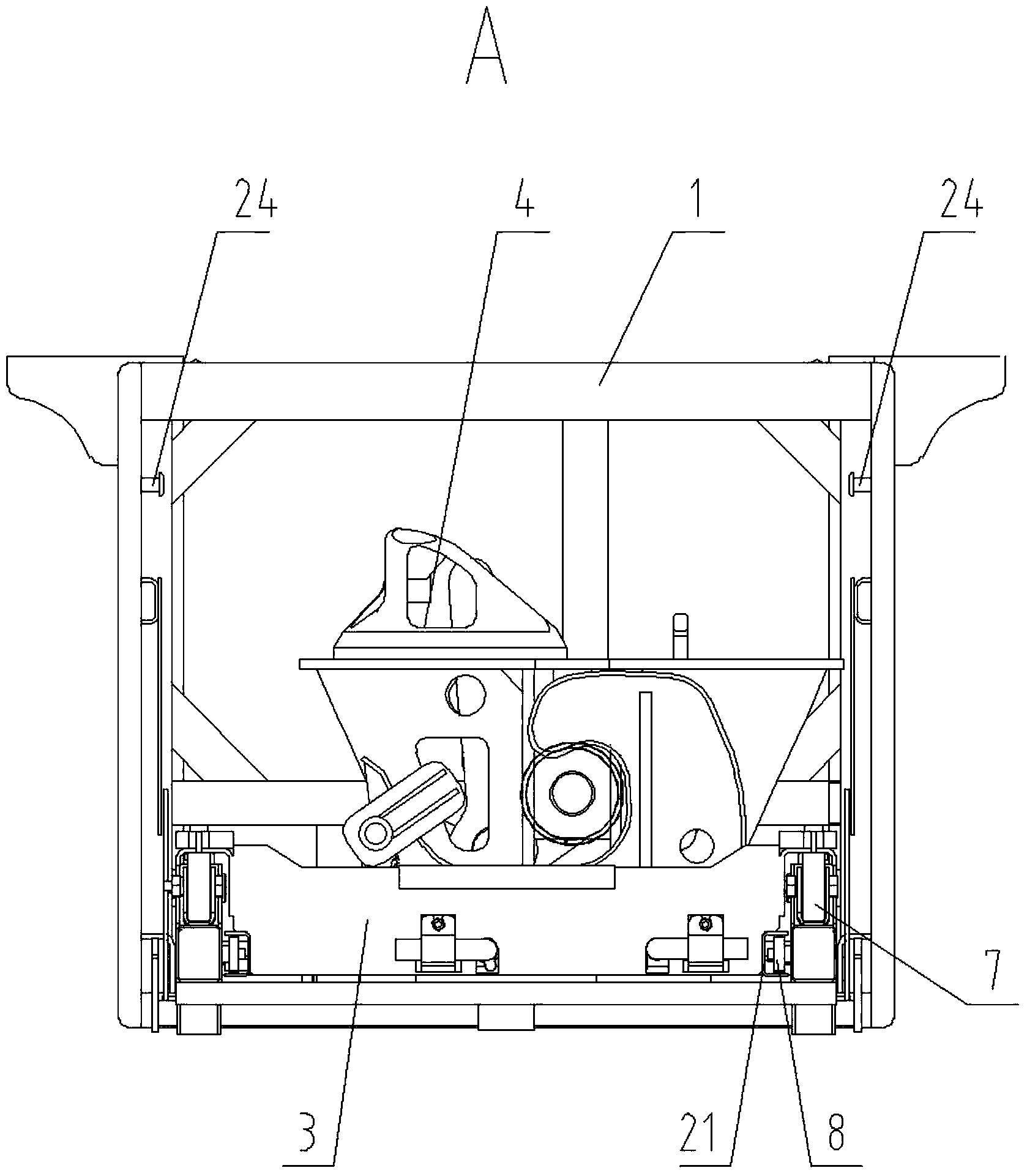

[0030] Such as figure 1 and figure 2 As shown, the rail vehicle coupler box includes a box body 1 and a box door 2 , and a trolley 3 is arranged inside the box body 1 , and the trolley 3 is used to place a transition coupler 4 .

[0031] Such as Figure 4 and Figure 5 As shown, the lower side of the box door 2 is hinged with the lower side of the box body 1, and the box door 2 can be rotated to open.

[0032] The box door 2 is composed of two vertical brackets 2a and a horizontal installation beam 2b. The lower sides of the two brackets 2a are respectively hinged with the lower side of the box body 1. The upper sides of the two brackets 2a are connected to the box body through a locking device. 1 is fixed, and the support 2a is a steel pipe with a square section.

[0033] Two connecting rods 5 are arranged between the casing 1 and each support 2a, and the two connecting rods 5 are connected in rotation, one end of one connecting rod 5 is fixedly connected with the casing...

Embodiment 2

[0045] The difference from Embodiment 1 is that the structure of the pulley 8 is removed, and the door roller 7 is arranged at the position where the pulley 8 is located in Embodiment 1, that is, the door roller 7 is arranged on the opposite bracket wall of the two brackets 2a. Similarly, rollers 6 in the box are arranged on both side walls in the box body 1, and the position of the corresponding rollers 6 in the box is lower than that in embodiment 1, and the distance between the side walls of the box body 1 will be longer. So that after the chamber door 2 is opened, the inner roller 6 and the chamber door roller 7 can form a row of rollers aligned, so that the dolly can slide.

[0046] The trolley 3 removes the structure of the upper guide rail 20, and slides and cooperates with the inner roller 6 and the door roller 7 through the lower guide rail 21 whose cross-sectional shape is "C" shape, and the "C" shaped openings of the two lower guide rails 21 face to both sides respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com