Silk fibroin/alginate hydrogel material and preparation method thereof

A technology of alginate and silk fibroin, which is applied in medical science, prosthesis, etc., achieves the effects of abundant raw material resources, simple and easy preparation method and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

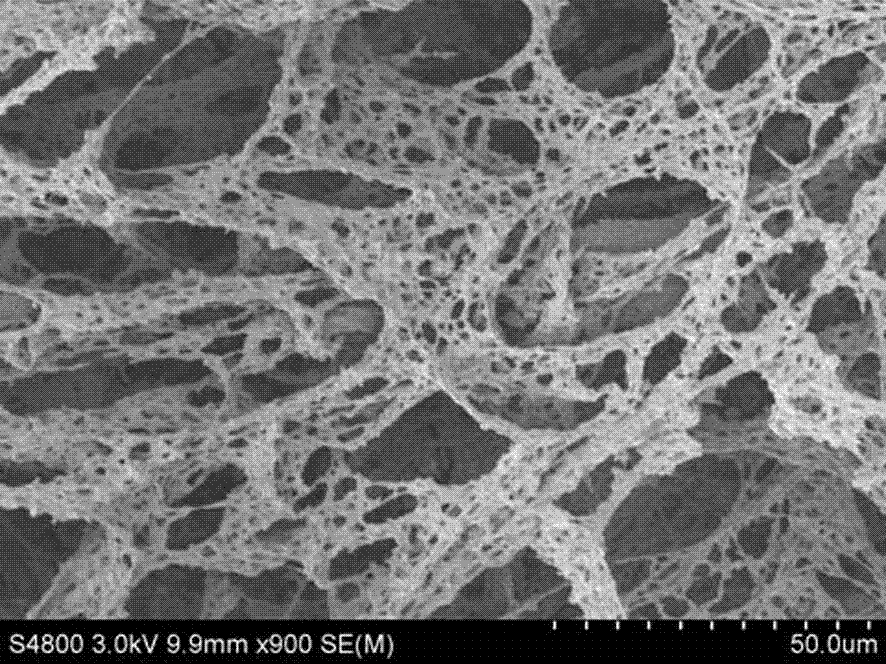

Image

Examples

Embodiment 1

[0025] The preparation of natural mulberry silk fibroin / sodium alginate hydrogel material comprises the following steps:

[0026] (1) Natural mulberry silk was degummed by boiling with 0.05% sodium carbonate solution for 30 min, and the pure silk fibroin fiber was obtained after repeated 3 times; the silk fibroin was dissolved in LiBr:C 2 h 5 OH:H 2 O=44:45:11 (mass ratio) Stir and dissolve in a water bath at a constant temperature of 70±2°C to obtain a regenerated silk fibroin protein solution; after dialysis, filtration, and concentration, a regenerated silk fibroin protein solution with a mass fraction of 30.36% is obtained;

[0027] (2) Dissolve 20g of sodium alginate in 80mL of deionized water, stir magnetically for 1 hour, and let stand for 24 hours to prepare a sodium alginate solution with a mass fraction of 20%;

[0028] (3) Add sodium alginate solution to silk fibroin solution, wherein the mass ratio of silk fibroin to sodium alginate is 7:3, then magnetically stir...

Embodiment 2

[0032] (1) Natural tussah silk was degummed by boiling 0.05% sodium carbonate solution for 30 minutes, and the pure tussah silk fibroin fiber was obtained after repeated 3 times; the silk fibroin was dissolved in LiSCN solution in a water bath at a constant temperature of 50±2°C Internal stirring and dissolving to obtain a regenerated silk fibroin solution; after dialysis and filtration, a regenerated silk fibroin solution with a mass fraction of 15.95% was obtained;

[0033] (2) Dissolve 10 g of potassium alginate in 90 mL of deionized water, stir magnetically for 1 h, and let stand for 6 h to prepare a potassium alginate solution with a mass fraction of 10%;

[0034] (3) Add the potassium alginate solution into the silk fibroin solution to ensure that the mass ratio of the silk fibroin and potassium alginate is 1:1, then magnetically stir for 2 hours, mix the solution evenly, adjust the pH value of the mixed solution to 4.0 with hydrochloric acid, and then , place the mixed ...

Embodiment 3

[0037] (1) Natural castor silk was degummed by boiling 0.05% sodium carbonate solution for 30 min, and obtained pure castor silk fibroin fiber after repeated 3 times; the silk fibroin was dissolved in lithium bromide / ethanol (40:60, mass Stir and dissolve in a water bath at a constant temperature of 70±2°C to obtain a regenerated silk fibroin protein solution; after dialysis and filtration, obtain a regenerated silk fibroin protein solution with a mass fraction of 5.37%;

[0038] (2) Dissolve 2.0 g of ammonium alginate in 98 mL of deionized water, stir magnetically for 1 h, and let stand for 2 h to prepare an ammonium alginate solution with a mass fraction of 2.0%;

[0039] (3) Add the ammonium alginate solution to the silk fibroin solution to ensure that the mass ratio of silk fibroin to ammonium alginate is 1:10, then magnetically stir for 1 hour, mix the solution evenly, adjust the pH value of the mixed solution to 6.0 with hydrochloric acid, and then , place the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com