Dye composition, dye, preparation methods thereof and raw material composition of dye

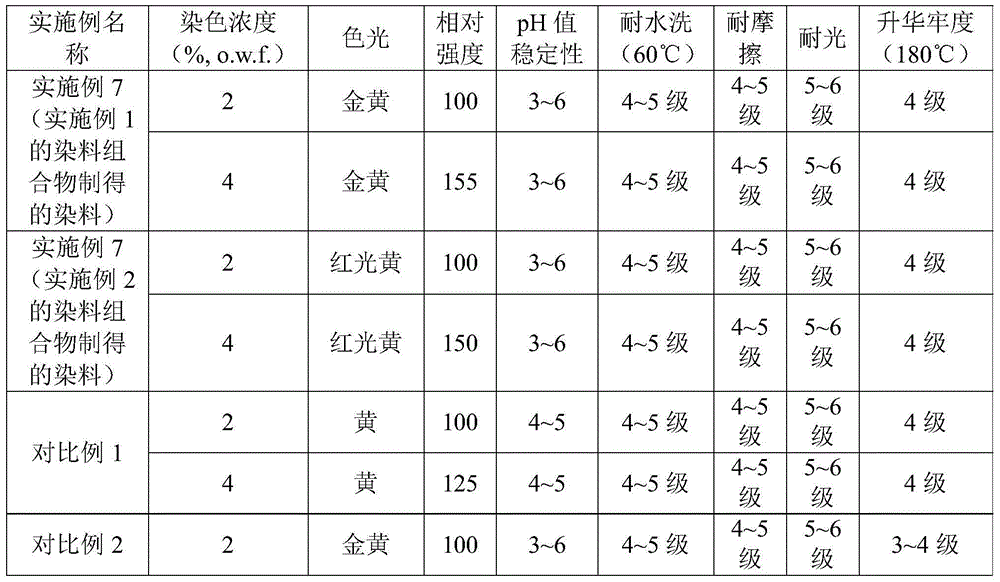

A dye composition and dye technology, applied in the direction of organic dyes, can solve the problems of insufficient lifting power, dyeing depth and fastness, and achieve the effect of bright color, excellent dyeing fastness and good level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

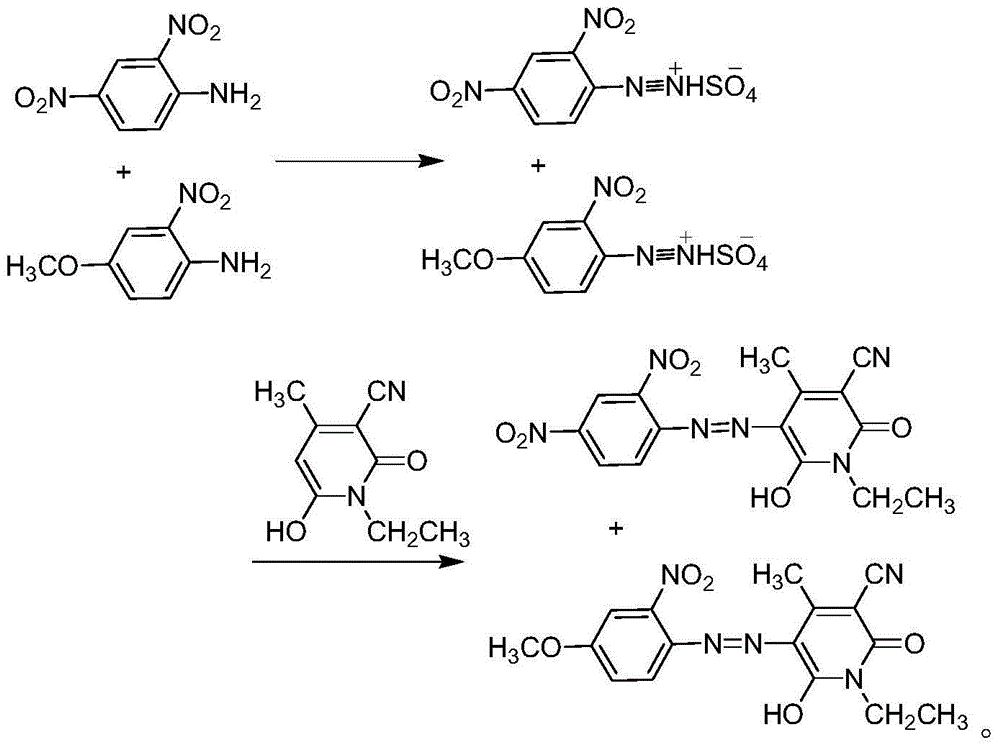

[0029] Embodiment 1: the preparation method of dye composition

[0030] After mixing 9.16 grams (0.05mol) of 2,4-dinitroaniline and 8.41 grams (0.05mol) of 2-nitro-4-methoxyaniline, add 15 grams of 70% sulfuric acid (0.11mol), and then Slowly add 40% sulfuric acid solution of nitrosylsulfuric acid dropwise at 15°C to 25°C to complete the diazotization reaction (detected by TLC), and the N-ethyl-3-cyano group with a mass percentage of 16% - A solution of 4-methyl-6-hydroxy-2-pyridone (18.20 grams) (add 30.6 grams of 30% sodium hydroxide solution to dissolve), a coupling reaction occurs at 0-10 ° C, and the end point of the reaction is detected by the percolation ring method . After the reaction, the temperature of the reaction system was raised to 65°C-75°C for 2 hours, filtered, and the product was washed with water until the pH value of the eluate was 6-7 to obtain a bright orange powder dye composition with a yield of 94.2%. The content is ≥98% by HPLC analysis, and the we...

Embodiment 2

[0031] Embodiment 2: the preparation method of dye composition

[0032] After mixing 11.72 grams (0.064mol) of 2,4-dinitroaniline and 6.05 grams (0.036mol) of 2-nitro-4-methoxyaniline, add 11 grams of 98% sulfuric acid (0.11mol), and then Slowly add 45% nitrosyl sulfuric acid dropwise at 18~22°C, and after the diazotization reaction is completed by HPLC detection, it is mixed with N-ethyl-3-cyano-4-methyl-6-hydroxyl with a mass fraction of 12%. - A solution of 2-pyridone (17.80 g) (dissolved in 95 g of 25% sodium carbonate solution) was subjected to a coupling reaction at -5 to 5° C., and the end point of the reaction was detected by the percolation ring method. After the reaction, the temperature of the reaction system was raised to 65°C-75°C for 2 hours, filtered, and the product was washed with water until the pH value of the eluate was 6-7 to obtain a bright orange powder dye composition with a yield of 94.8%. The content is ≥98% by HPLC analysis, and the weight percentag...

Embodiment 3

[0033] Embodiment 3: the preparation method of dye composition

[0034]After mixing 4.39 grams (0.024mol) of 2,4-dinitroaniline and 12.78 grams (0.076mol) of 2-nitro-4-methoxyaniline, add 85 grams of 70% sulfuric acid (0.61mol), and then Slowly add 20% nitrosylsulfuric acid dropwise at 28~32°C, after the diazotization reaction is completed by HPLC detection, and N-ethyl-3-cyano-4-methyl-6-hydroxyl with a mass fraction of 16% - A solution of 2-pyridone (20.50 g) (dissolved with 38.6 g of 50% potassium hydroxide solution) undergoes a coupling reaction at 8 to 15° C., and detects the end point of the reaction by the percolation ring method. After the reaction, the temperature of the reaction system was raised to 65°C-75°C for 2 hours, filtered, and the product was washed with water until the pH value of the eluate was 6-7 to obtain a bright orange powder dye composition with a yield of 95.3%. The content is ≥98% by HPLC analysis, and the weight percentage of component B is 75.0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com