Local flavor yeast and composition thereof

A flavor yeast and composition technology, applied in the field of steamed bread, can solve the problems of complex and limited steamed bread production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

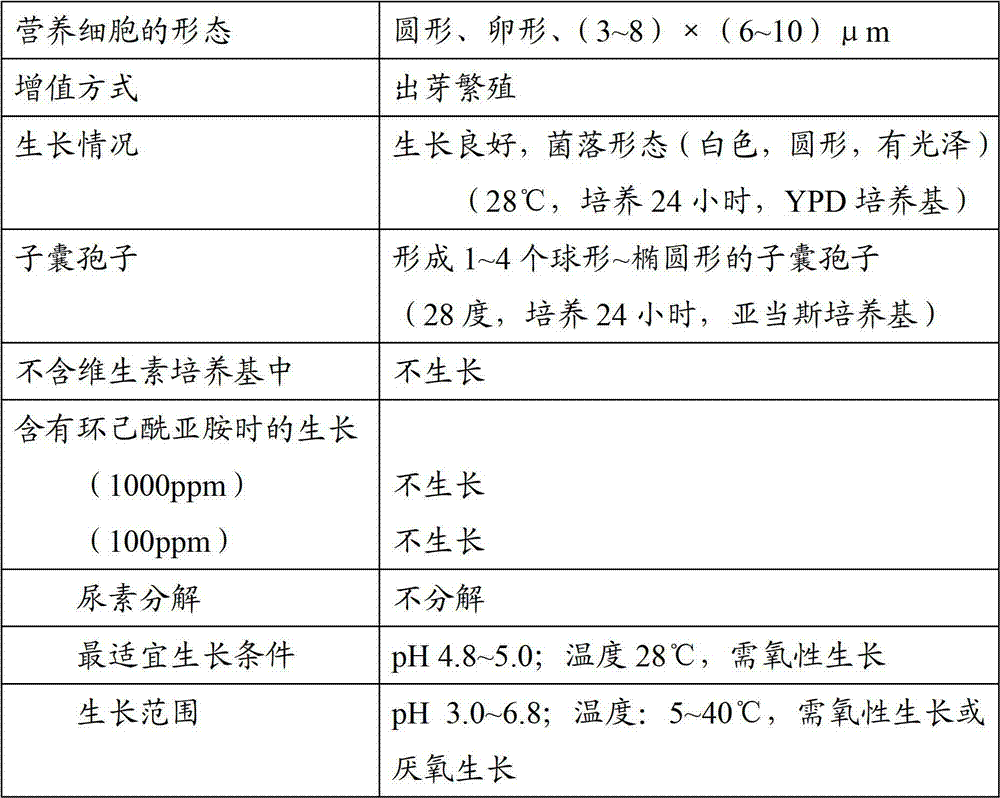

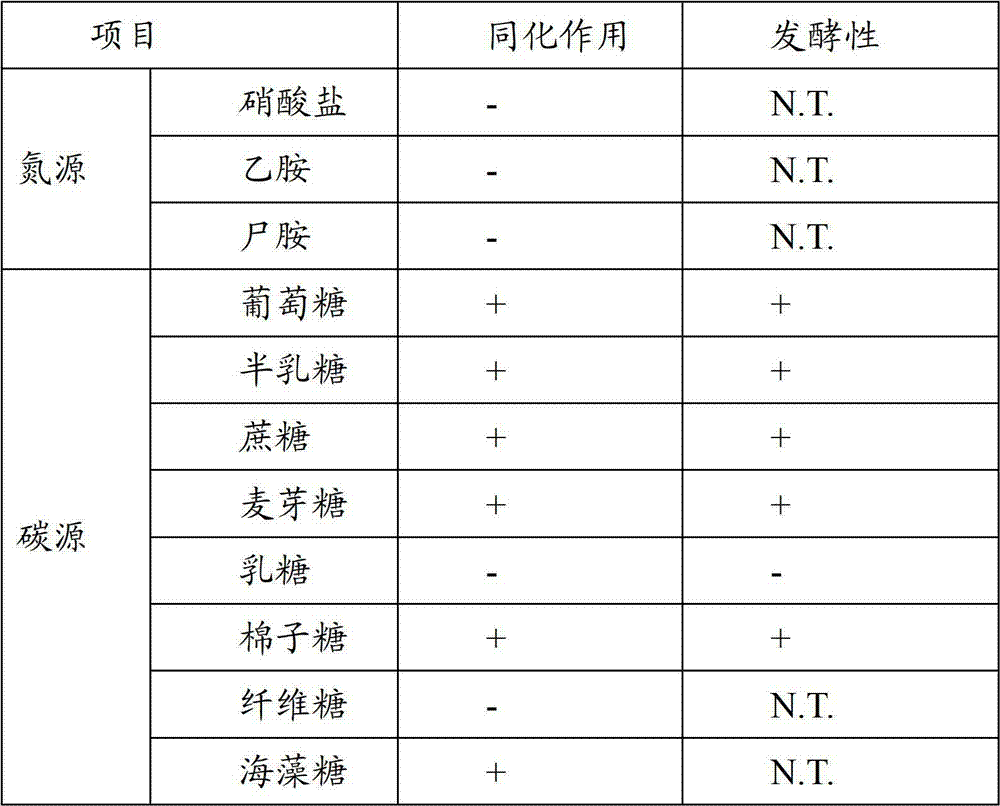

Method used

Image

Examples

Embodiment 1~6

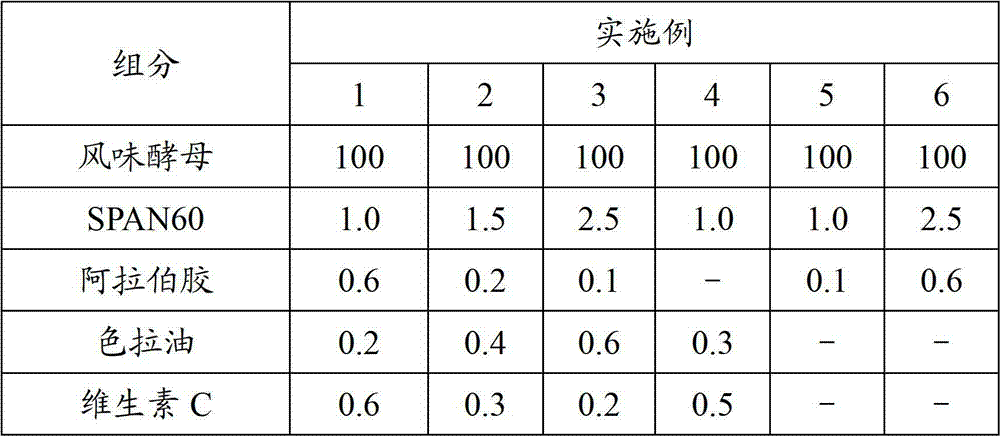

[0039] The preparation of embodiment 1~6 yeast composition of the present invention

[0040] The flavor yeast cultivated by the molasses method is collected, washed and centrifuged to obtain the fresh yeast of the flavor yeast of the present invention.

[0041] The flavor yeast cultivated by the molasses method is collected, washed and centrifuged, then granulated and rapidly dried at low temperature to obtain the dry yeast of the present invention.

[0042] Collect, wash and centrifuge the flavor yeast cultivated by the molasses method to obtain the fresh yeast of the present invention, and then add each component according to the proportion shown in Table 3 to obtain the yeast composition of Examples 1-6.

[0043] Table 3 Examples of yeast compositions of the present invention

[0044]

[0045] Note: SPAN60 in the table is the trade name of sorbitan monostearate; yeast is absolute dry weight.

Embodiment 7

[0046] The proofing ability of embodiment 7 yeast composition of the present invention

[0047] Commercially available ordinary sugar-free yeast and ordinary high-sugar yeast were used as a comparison, and the proofing ability was evaluated according to their proofing time. Knead ordinary sugar-free yeast, ordinary high-sugar yeast and the yeast composition of the present invention prepared in Examples 1-6 according to Table 4, and place the reconciled dough in a proofing box (the temperature is controlled at about 26°C) , and then put the proofing box in a proofing box with a temperature of 35-37°C and a relative humidity of 78-80%. The proofing time starts when the proofing box is put into the proofing box and reaches the top of the box at the highest point of the dough. When the time period ends, this time period is the face-to-face time; see Table 5 for the face-to-face time of each group.

[0048] Table 4 Fermented Dough Component Table

[0049]

[0050] Note: In thi...

Embodiment 8

[0054] Embodiment 8 Flavor evaluation of yeast composition of the present invention

[0055]Evaluation method of smell: make steamed buns according to the components with sugar content of 0% in Table 4, stipulate that the fermented flavor of steamed buns in the same group is divided into 5 grades, and the evaluators evaluate them according to their own preferences. Points are given, the best score is 5 points, descending in turn, for experimental groups with similar smells or similar preferences, parallel scores are allowed.

[0056] The evaluation of the results is mainly through the olfactory sensory evaluation of people of different occupations and different age groups. The steamed buns made by them were randomly distributed, and consumers made a comparative evaluation of them. The number of people participating in the odor evaluation was 20. The results are shown in Table 6 and Table 7. Because too many samples in the same group would affect the judgment results, 5 sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com