Automatic cut material sewing equipment and method

A sewing and automatic technology, applied in the field of garment manufacturing, can solve the problems of high labor intensity of operators, low production efficiency, complex production process, etc., to reduce the complexity of equipment, reduce labor costs, and reduce operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

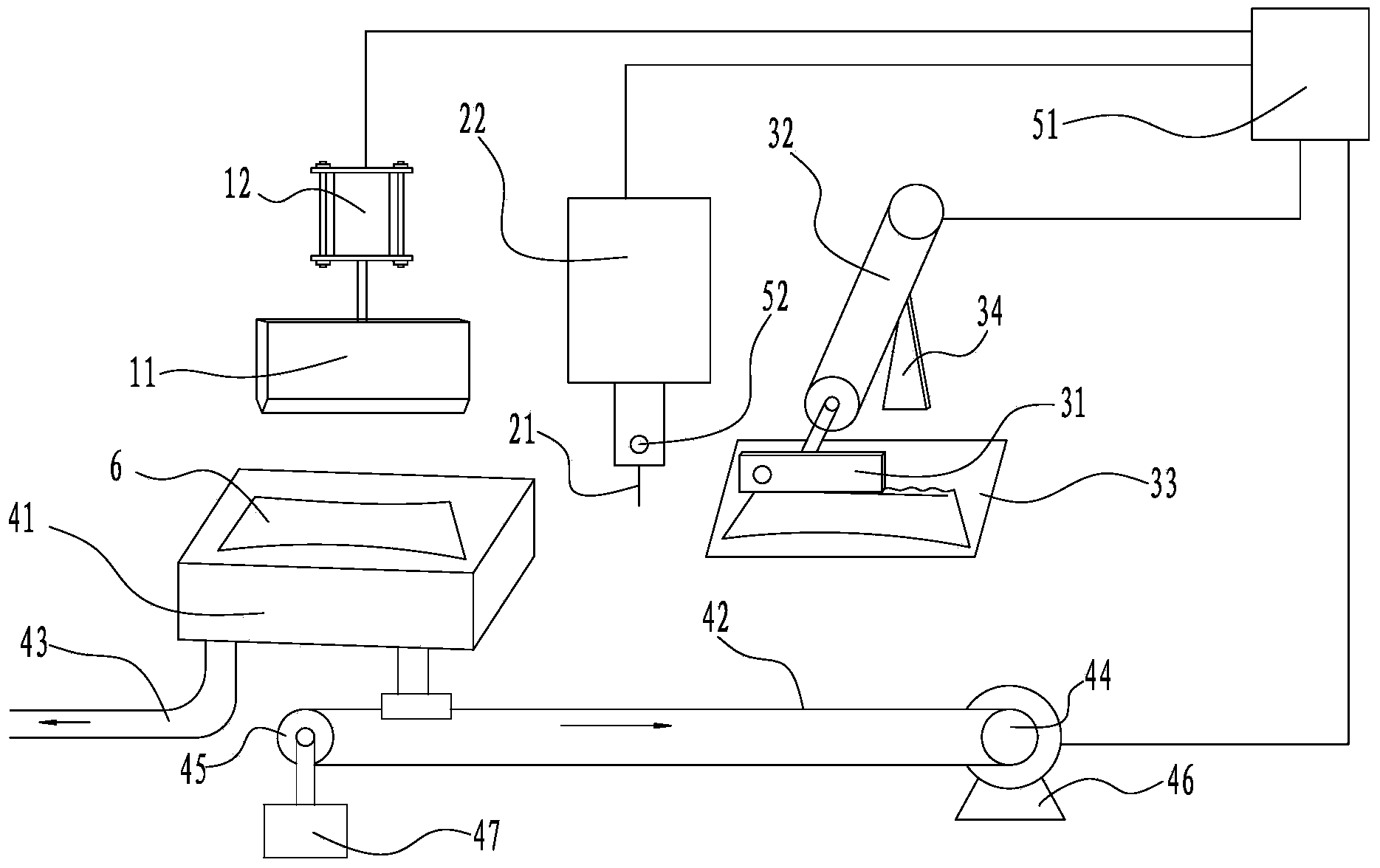

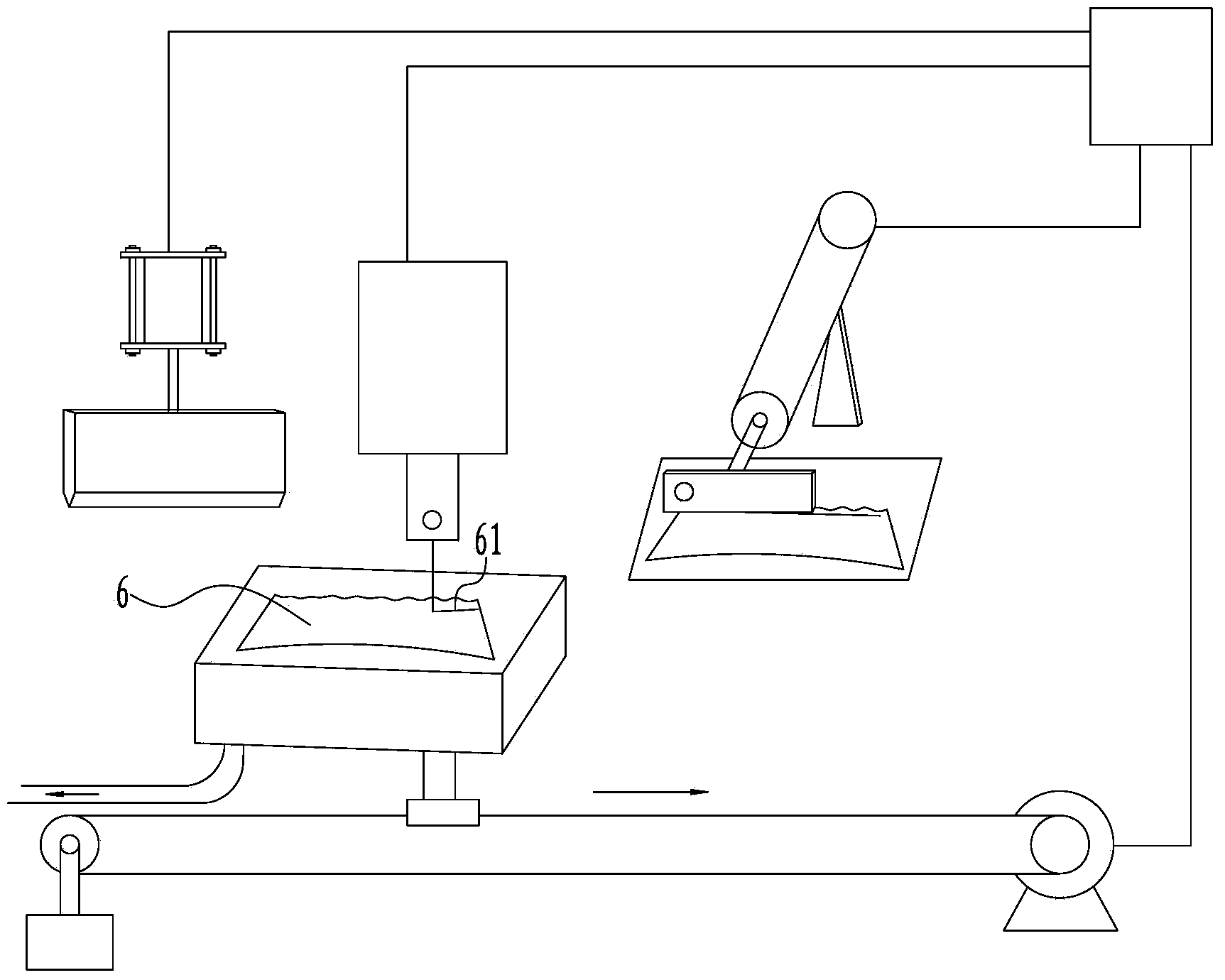

[0035] A kind of automatic material cutting sewing equipment, such as Figure 1-3 As shown, it includes the control system, and the cutting mechanism, sewing mechanism, material receiving mechanism, conveying mechanism and bottom mold controlled by the control system.

[0036] The cutting mechanism includes a cutter 11 and a cutter driving cylinder 12. The cutter driving cylinder 12 has a first telescopic rod for driving the cutter 11 to move up and down, and the cutter 11 is mounted on the first telescopic rod.

[0037] The sewing mechanism includes a bur 21 and a sewing driving device 22 .

[0038] The receiving mechanism includes a scraper 31, a scraper driving cylinder 32, a support rod 34 and a receiving platform 33, the scraper driving cylinder 32 has a second telescopic rod, and the scraper 31 is installed on the second telescopic rod On, and the edge of the wiper 31 is provided with a soft rubber layer. The wiper driving cylinder 32 is hingedly mounted on a support r...

Embodiment 2

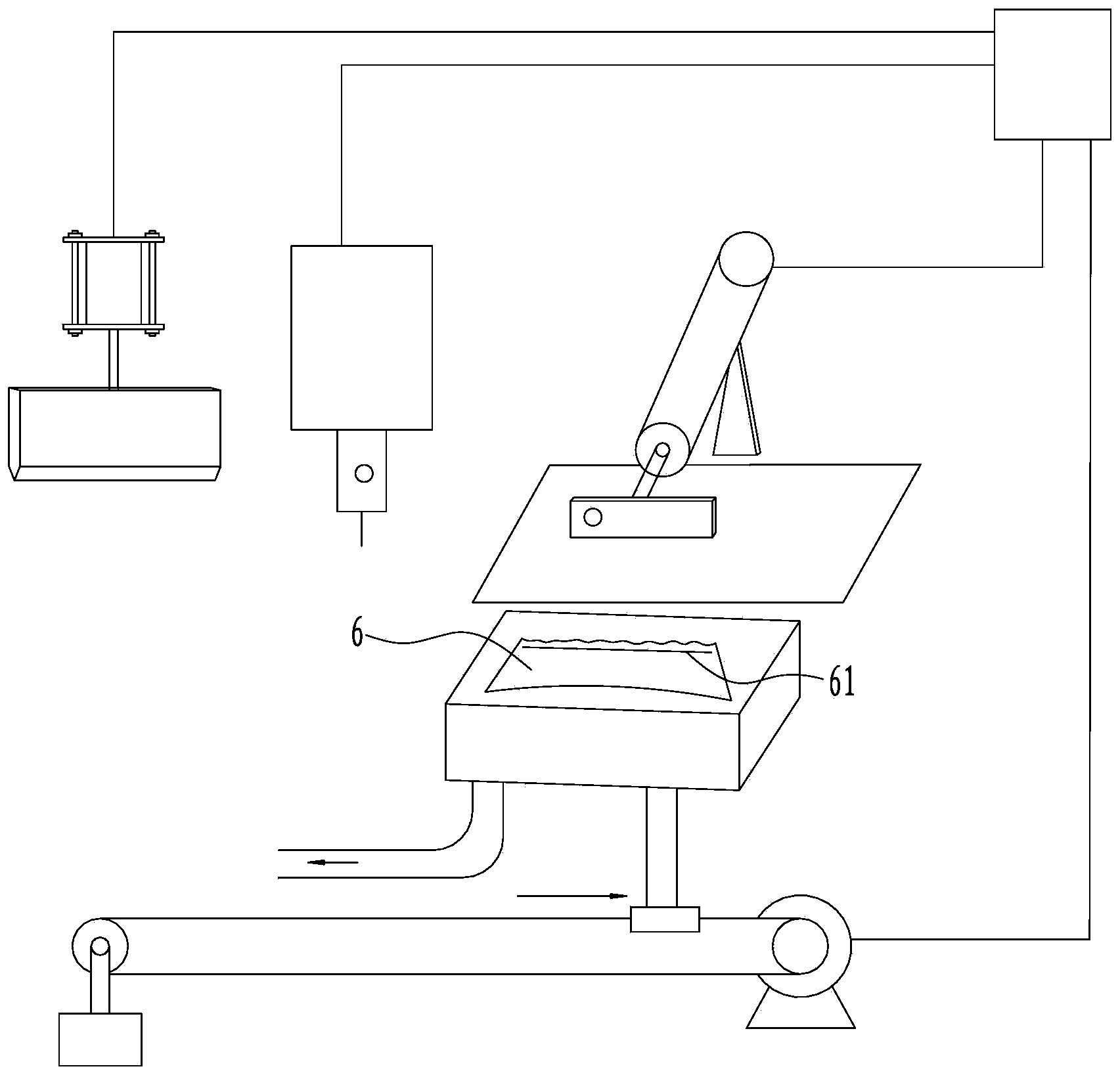

[0049] An automatic material-cutting sewing device includes a control system, and a cutting mechanism, a sewing mechanism, a material receiving mechanism and a conveying mechanism controlled by the control system.

[0050] The cutting mechanism includes a cutter and a cutter driving cylinder, the cutter driving cylinder has a first telescopic rod for driving the cutter to move up and down, and the cutter is mounted on the first telescopic rod.

[0051] The sewing mechanism includes a bur and a sewing driving device.

[0052] The receiving mechanism includes a scraper, a scraper driving cylinder and a receiving platform. The scraper driving cylinder is installed on the mobile platform, and the scraper driving cylinder has a second telescopic rod, and the second telescopic rod moves along the Flat stretch. The scraper is installed on the second telescopic rod, and the edge of the scraper is provided with a soft rubber layer. The receiving platform is arranged at the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com