Valve seat structure of track ball valve

A technology of valve seat and ball valve, which is applied in the field of seat structure of orbital valves. It can solve the problems of time-consuming and laborious, cumbersome sealing surface, and can not meet the long-term stable sealing of valves, and achieve zero leakage and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

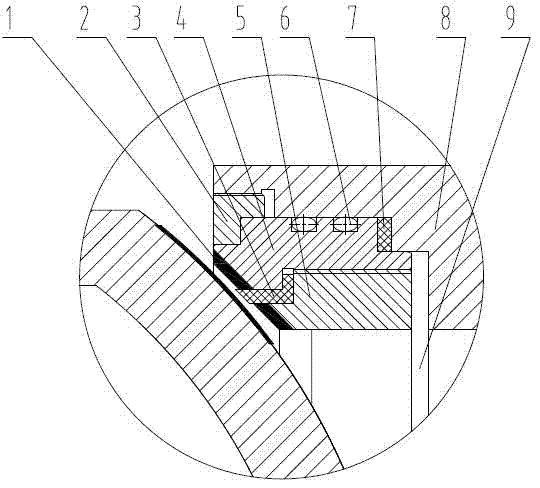

[0013] Such as figure 1 As shown, a valve seat structure of an orbital ball valve includes a valve seat. The valve seat includes an upper valve seat 4 and a lower valve seat 5. The contact surfaces between the upper valve seat 4 and the lower valve seat 5 are all stepped surfaces. A soft sealing ring 3 is provided between the inner stepped surfaces of the valve seat, and the soft sealing ring 3 protrudes outward from the upper and lower valve seat sealing surfaces 1, and the outer stepped surfaces of the upper and lower valve seats are fixedly connected by threads. The axial contact end surface of the upper valve seat 4 and the valve body 8 is a stepped surface, and a flexible graphite sealing ring 7 is arranged between the lower end surface of the stepped surface and the valve body, and the upper end surface of the stepped surface is flush with the end surface of the lower valve seat 5, and There is a compression gap 9 between the upper valve seat 4 and the valve body 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com