Water and electricity independent dual-core electromagnetic induction fast heating water heater

An electromagnetic induction and magnetic induction technology, applied in the field of quick-heating electromagnetic induction water heaters, can solve the problems of user protection limitations, uneven water temperature in the water tank, slow water temperature rise, etc., and achieve the effects of low noise, fast heating, and uniform water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Various embodiments of the present invention will be described in detail below, examples of which are illustrated with reference to the accompanying drawings and described below. While the invention will be described in conjunction with exemplary embodiments, it should be understood that the invention is not limited to these exemplary embodiments. On the contrary, the present invention includes not only these embodiments but also various modifications and improvements.

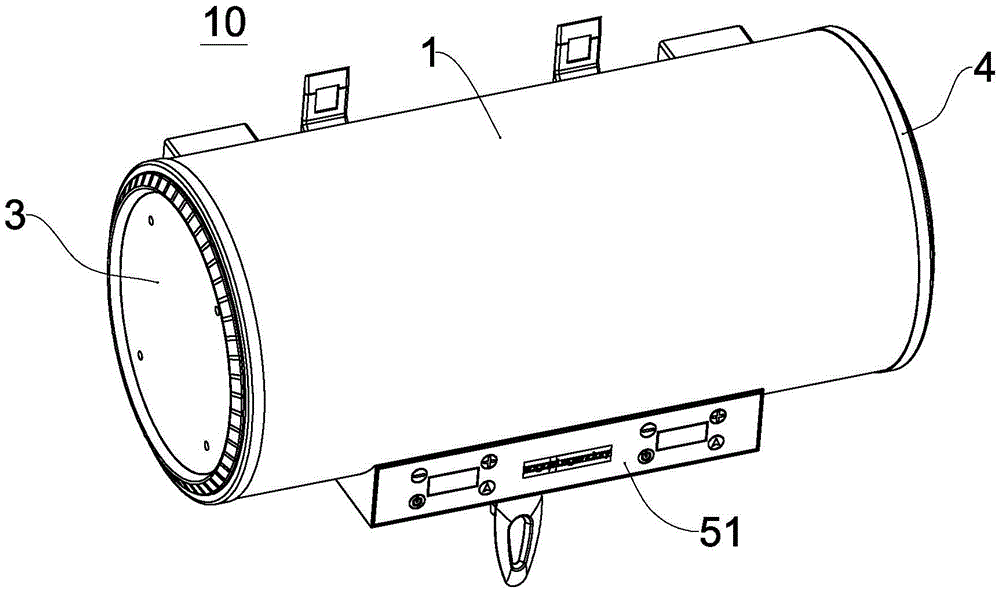

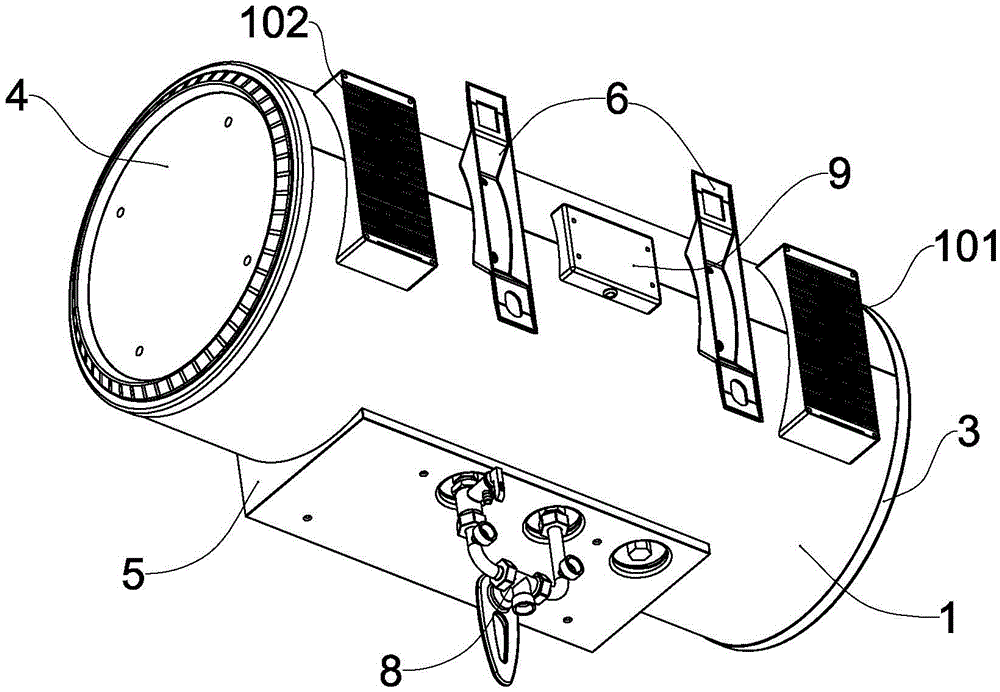

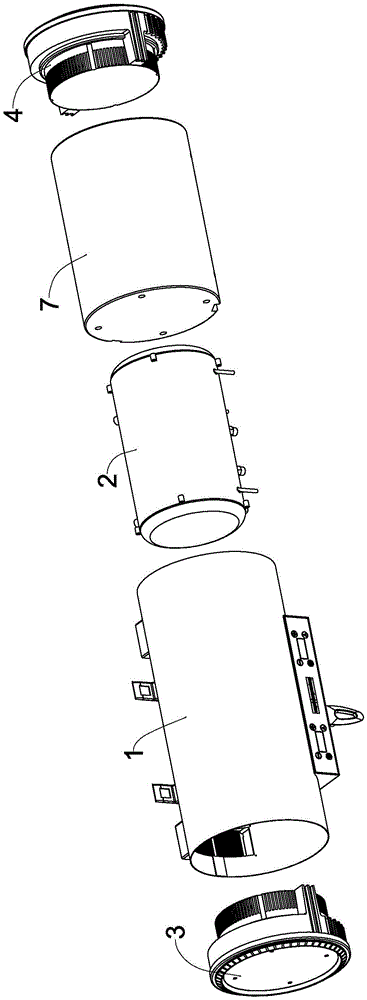

[0046] Figure 1 to Figure 5 Shows an instant water heater 10 according to an embodiment of the present invention, which includes a casing 1, a water tank 2, a first electromagnetic heating unit 3, a second electromagnetic heating unit 4, a control unit 5, etc., and the casing 1 is roughly cylindrical , the water tank 2 is located inside the shell 1, and the outer surface of the water tank 2 is covered with a heat-insulating layer 7. The heat-insulating layer 7 adopts the integral foaming polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com