Detection system for single-jet-pipe rocket launch water-spray cooling noise-reduction effect

A rocket launch, water spray cooling technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of powerlessness in theoretical fine-grained evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

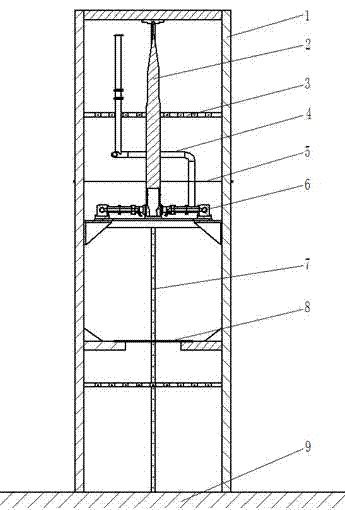

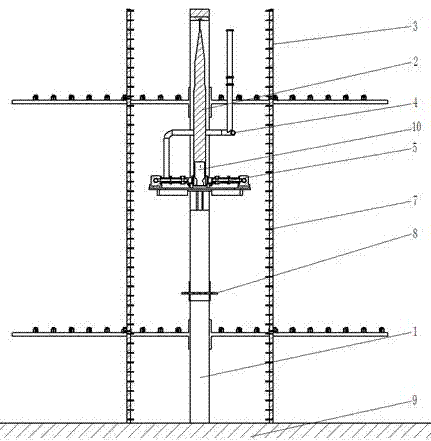

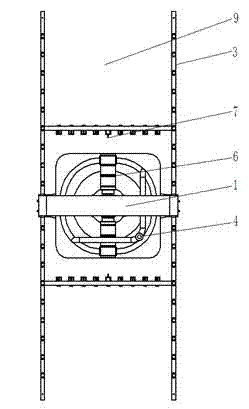

[0027] see Figure 1-Figure 3 , The detection system used in the present invention mainly consists of gantry 1, simulated rocket 2, rocket positioning adjustment equipment 5, water spray device 6, noise detection equipment, gas flow field and gas flow ablation intensity detection equipment, etc.

[0028] The gantry 1 is mainly composed of two uprights and the upper hanging beam. During the test, the two uprights of the gantry 1 are placed parallel and vertically on the foundation 9, and cooperate with the upper hanging beam to safely and reliably fix the rocket and other above-mentioned equipment.

[0029] The simulated rocket 2 is used as a test rocket, which is mainly used to generate the gas flow medium and gas flow noise sound source conditions required for the test. In order to cooperate with the evaluation of the gas flow field, gas flow ablation intensity and jet flow noise law, the thrust chamber of the simulated engine needs to Place pressure and temperature sensors. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com