2D controller design method for interval time lag in injection modeling process

A design method and controller technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems affecting system stability, system performance, poor anti-interference ability, and high product defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

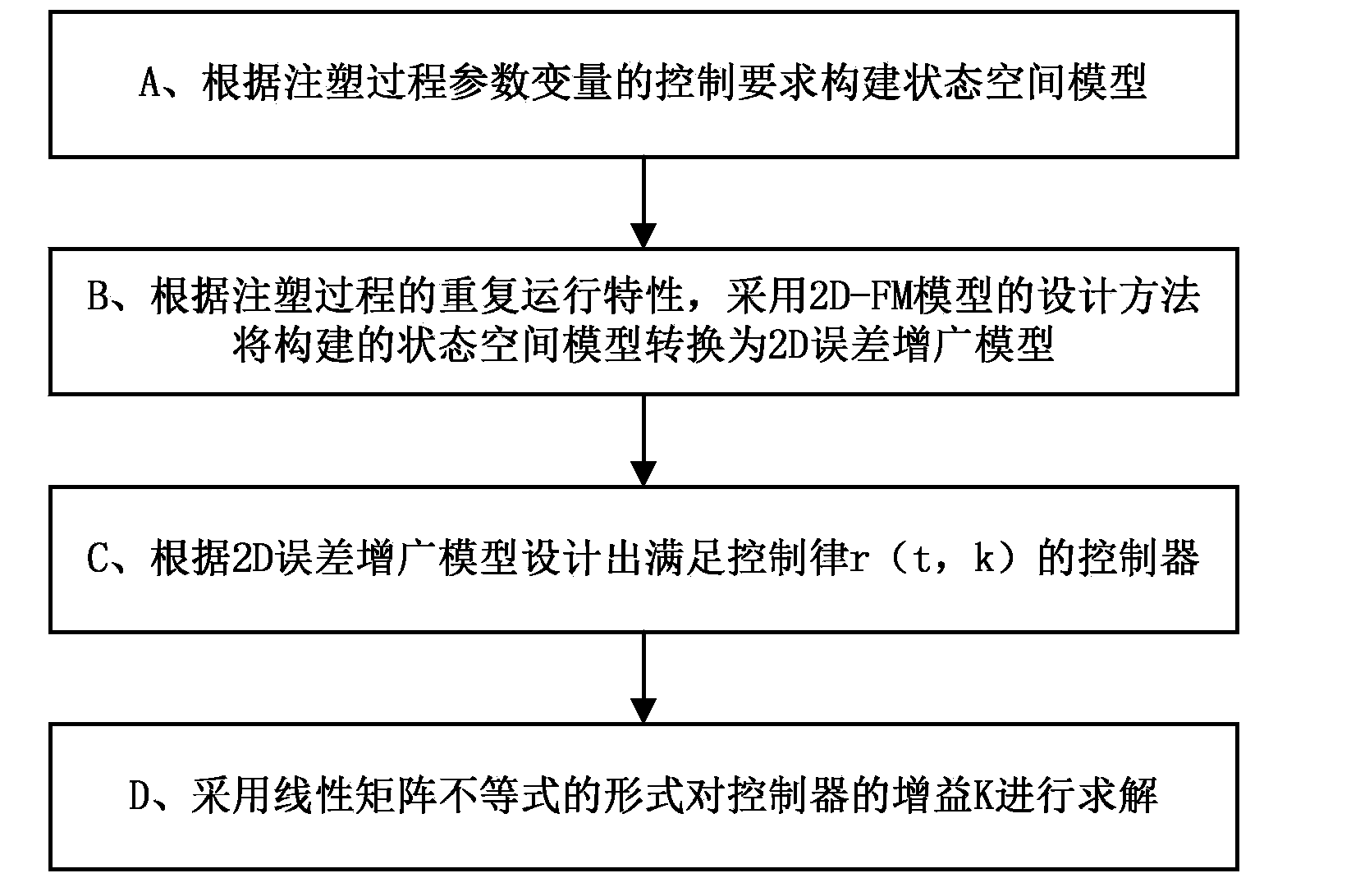

Method used

Image

Examples

Embodiment 1

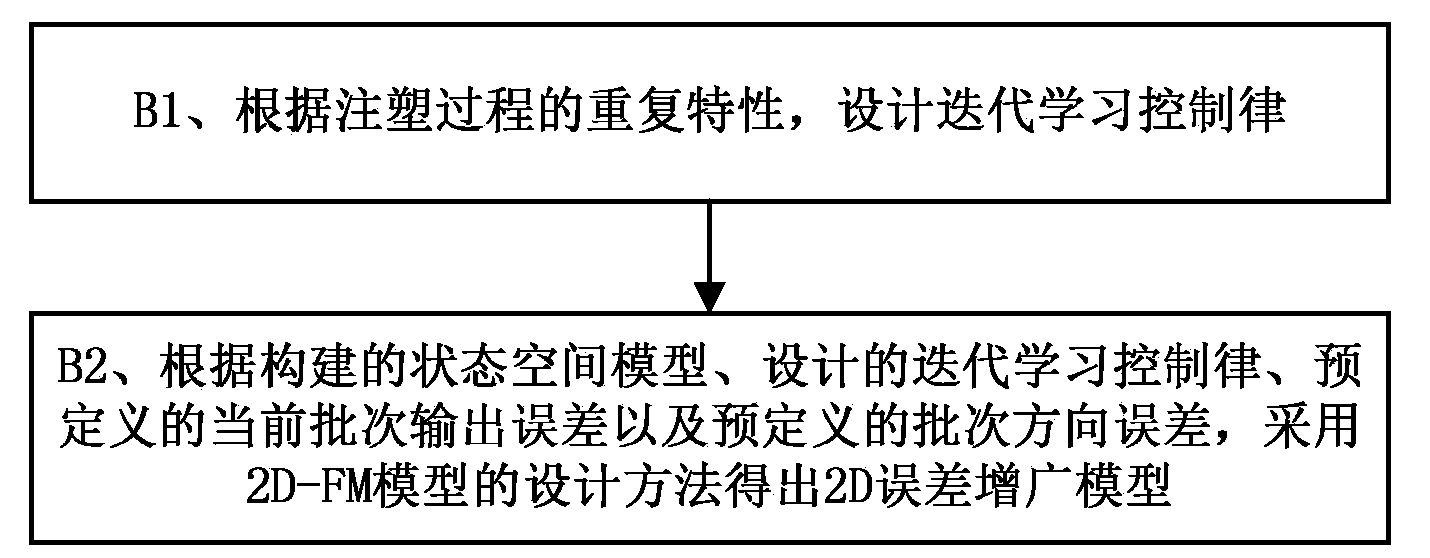

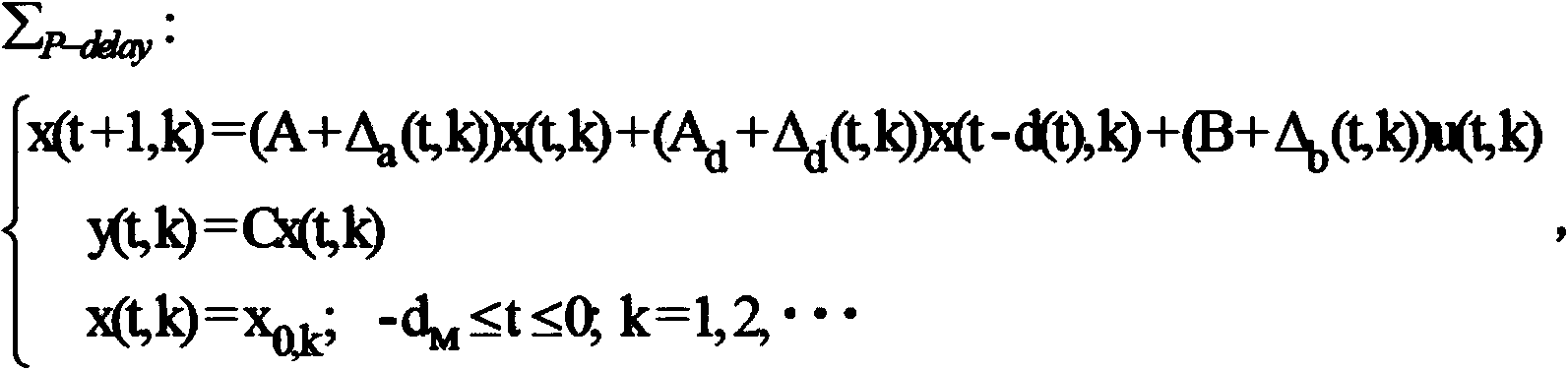

[0061] This embodiment describes the specific process of converting the constructed state space model into a 2D error augmented model by using the design method of the 2D-FM model.

[0062] The concrete process that the present invention converts the state-space model of construction into 2D error augmentation model is as follows:

[0063] First, according to the repetitive characteristics of the injection molding process, the iterative learning control law is designed as:

[0064] ∑ ilc u (t,k)=u(t,k-1)+r(t,k)(u(t,0)=0,t=0,1,2,...,T)...(1):

[0065] Then, define the current batch output error as:

[0066] e(t,k)=y(t,k)-y d (t)...(2)

[0067] And define the batch direction error as:

[0068] x Δ (t,k)=x(t,k)-x(t,k-1)...(3)

[0069] According to formulas (1), (2) and (3), it can be obtained:

[0070] x Δ (t+1,k)

[0071] =x(t+1,k)-x(t+1,k-1)

[0072] =(A 1 +Δ a (t,k))(x(t,k)-x(t,k-1))+(A d +Δ d (t,k))(x(t-d(t),k)-x(t-d(t),k-1)) ...(4)+(B+Δ b (t,k))r(t,k)+Iω(t,k...

Embodiment 2

[0083] This embodiment describes the specific process of solving a given stability criterion (that is, solving the gain K of the controller in the form of linear matrix inequality).

[0084] The specific method is as follows:

[0085] First minimize γ, and let L i >0, Q - 1 > 0 , W - 1 > 0 , W ~ 1 > 0 , x 1>01, R ~ 1 L ~ 1 L ~ ...

Embodiment 3

[0088] This embodiment is an embodiment of the present invention applied to injection speed control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com