Solid insulating piece surface treatment technology

A solid insulation and surface treatment technology, which is applied in the field of electric power engineering, can solve the problems such as the decline of insulation parts' moisture-proof and dust-proof effects, the poor moisture-proof and dust-proof effect of the ground layer, and the loss of the ground layer, so as to achieve dust-proof and moisture-proof Good effect, improve environmental adaptability and beautify the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

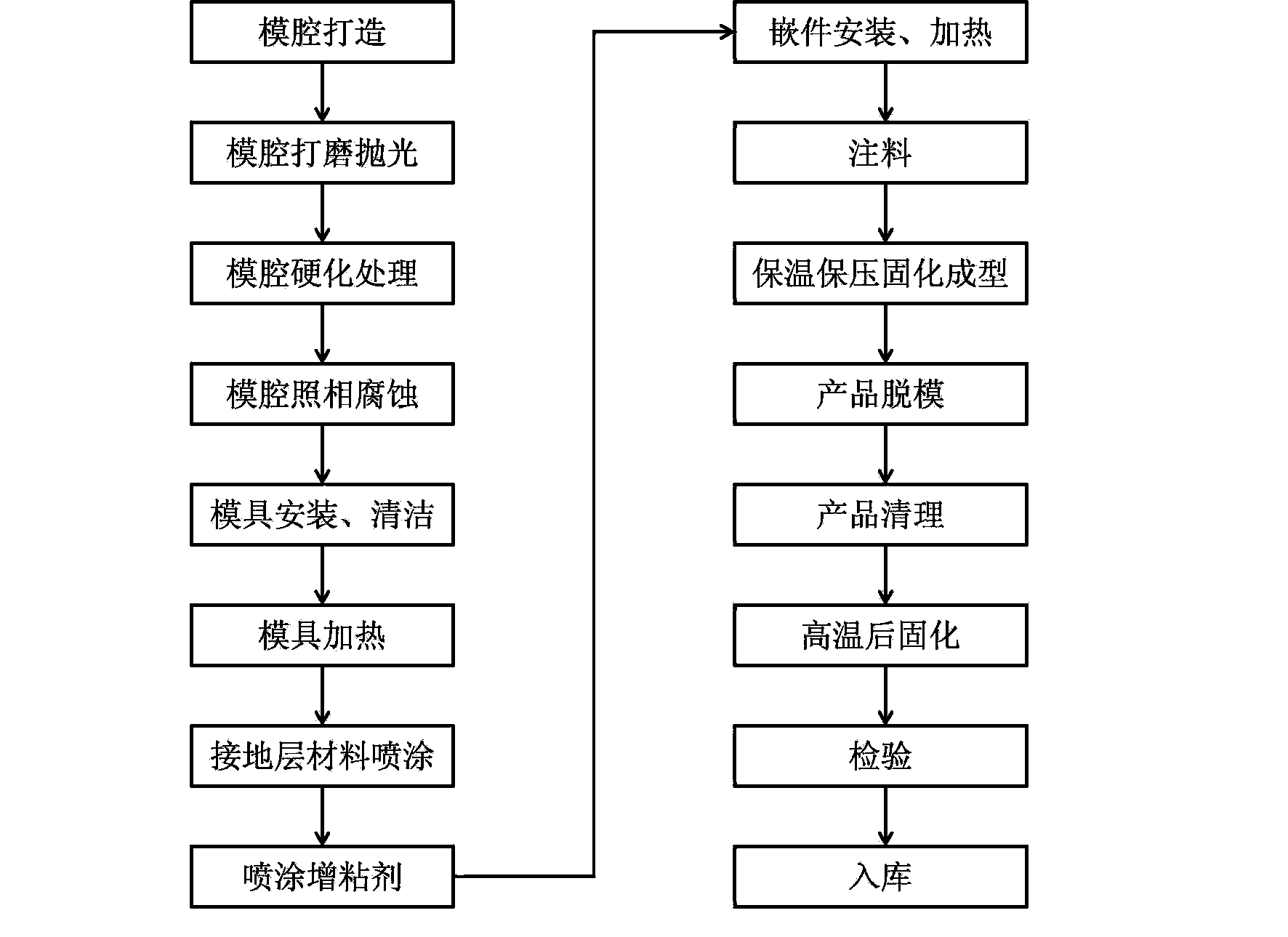

[0024] Embodiment 1: the production technology of 12KV solid insulation box, carry out according to the following steps:

[0025] A. Mold processing process: Manufacture the mold cavity according to the process of solid insulation box, polish and polish the processed mold cavity until it reaches the effect of mirror surface; harden the polished and polished mold cavity with nitriding to strengthen the mold cavity After that, according to the design requirements, different textures are first formed with negative films, and then pasted on the mold cavity, and the mold cavity is corroded with an industrial corrosive agent, so that the surface of the product has a special texture, thereby completing the treatment of the mold cavity;

[0026] B. Mold production stage: Install and clean the mold cavity (mold) processed above, and then heat the mold. The heating temperature is preferably 135°C-145°C, and the time is preferably 0-3min. After completion, spray a liquid conductive mater...

Embodiment 2

[0031] Embodiment 2: The production technology of 24KV solid single-phase melting bin, carry out according to the following steps:

[0032] A. Mold processing process: The mold cavity is manufactured according to the process of solid single-phase melting bin, and the processed mold cavity is polished until it reaches the effect of mirror surface; the polished mold cavity is hardened by nitriding to strengthen The strength of the mold cavity; then, according to the design requirements, firstly use negative films to form different textures, and then paste them on the mold cavity, and use industrial corrosive agents to corrode the mold cavity, so that the product surface has a special texture, thereby completing the treatment of the mold cavity ;

[0033] B. Mold production stage: Install and clean the mold cavity (mold) processed above, and then heat the mold. The heating temperature is preferably 140°C-150°C, and the time is preferably 0-3min. After completion, spray a liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com