A multi-step porcelain tube and a gas discharge tube made of the multi-step porcelain tube

A gas discharge tube and multi-step technology, which is applied to overvoltage arresters, circuits, and electrical components using spark gaps, can solve problems such as high voltage protection level, melting of built-in electrode pieces, increased arc voltage and freewheeling capacity, etc. Achieve the effect of increasing the creepage distance between the gaps, enhancing the freewheeling capability, and increasing the arc voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

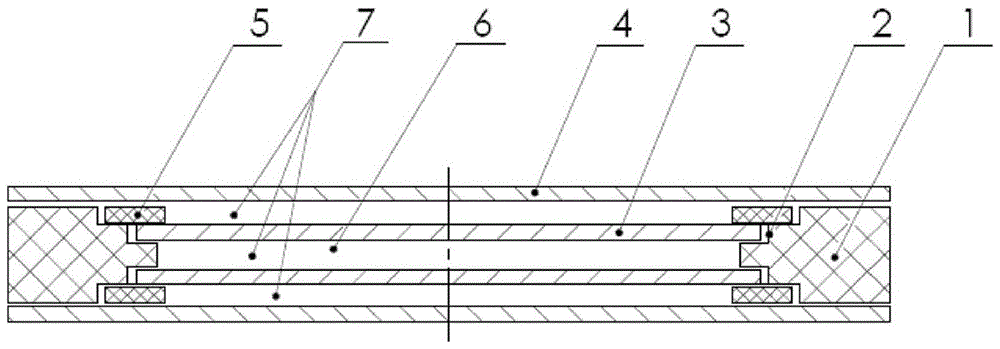

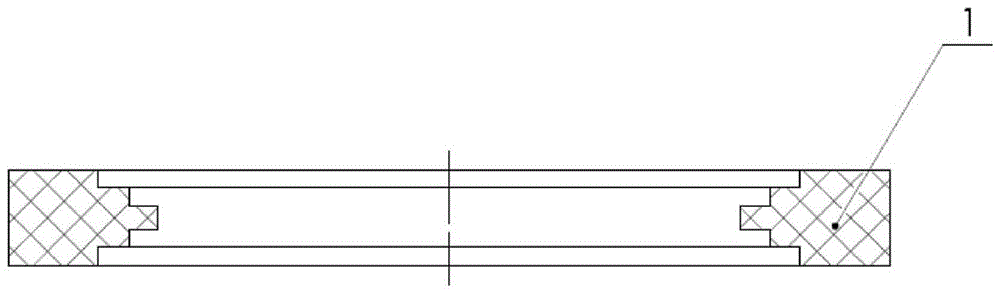

[0022] Such as figure 1 As shown, a multi-step porcelain tube includes a porcelain tube body 1, and a plurality of steps 2 are arranged inside the porcelain tube body 1.

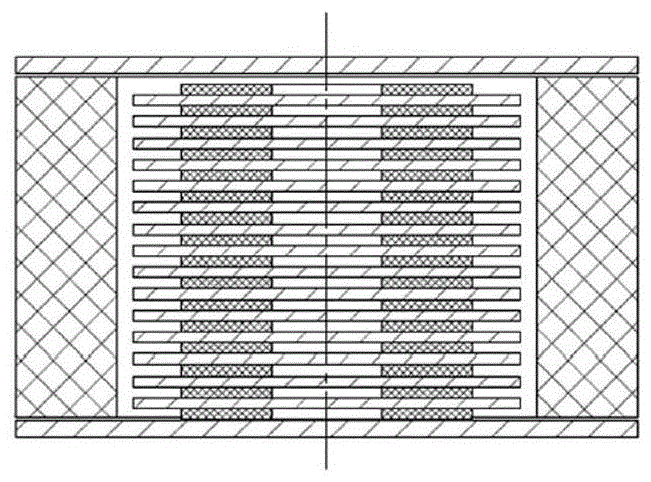

[0023] A multi-layer gas discharge tube, a first discharge electrode 3 and a second discharge electrode 4 are arranged on the step 2 of the multi-step porcelain tube, and an isolating ceramic sheet 5 is arranged between the first discharge electrode 3 and the second discharge electrode 4, The cavity 6 formed by the two second discharge electrodes 4 and the porcelain body 1 is filled with inert and non-inert mixed gas, and a three-layer discharge gap 7 is formed.

[0024] When using the present invention as a protective device, the arc voltage is increased by connecting multilayer discharge tubes in series, thereby cutting off freewheeling. The protective device includes n gas discharge tubes, which are welded together under the condition of 850 degrees by brazing. There are 3 discharge gaps in each layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com