12/14 bearingless permanent magnet biased switched reluctance motor

A switched reluctance motor and permanent magnet bias technology, which is applied in the direction of magnetic attraction or thrust holding devices, electromechanical devices, electrical components, etc., can solve the problems of unstable magnetic field of the motor, large copper consumption of the motor, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

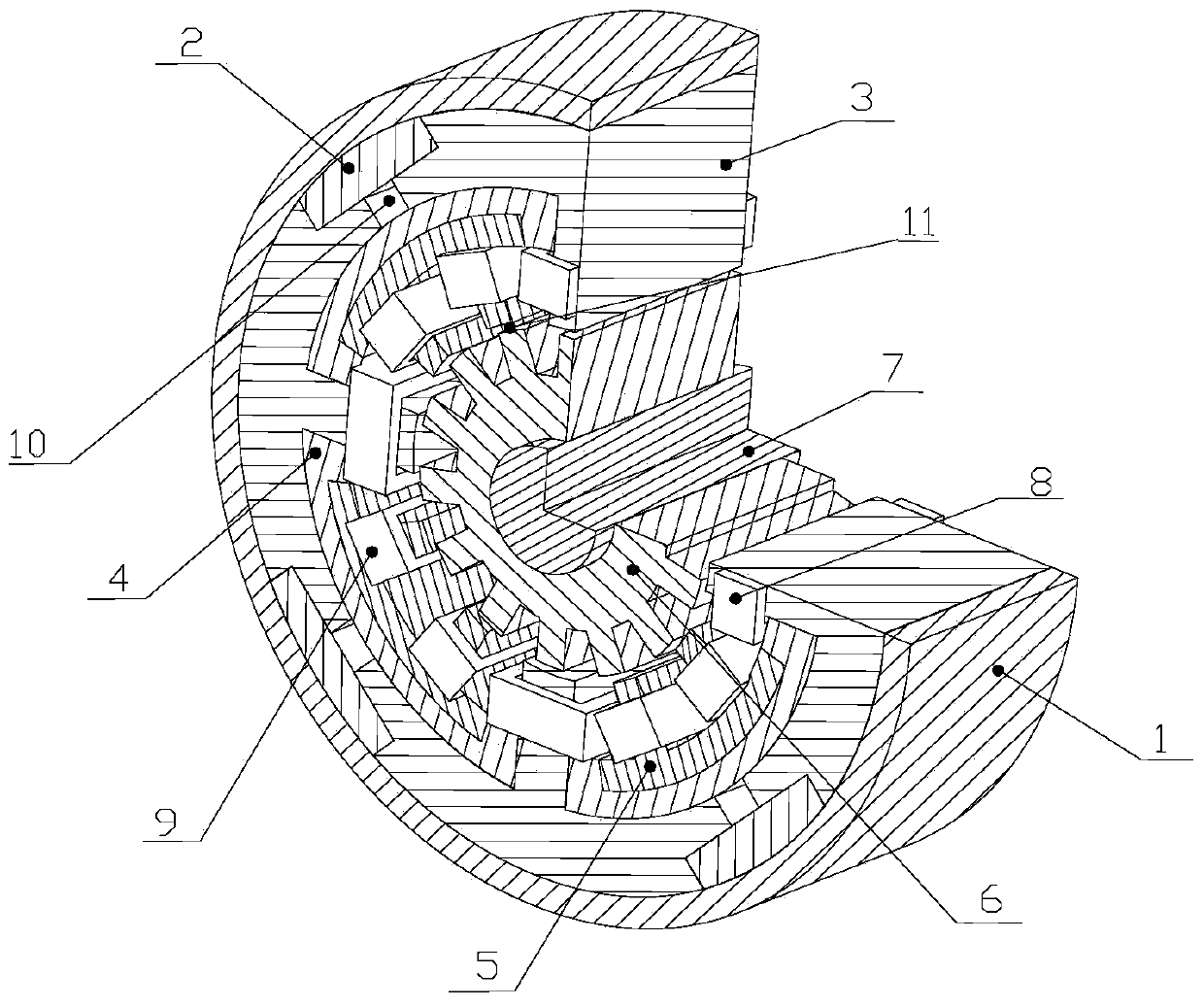

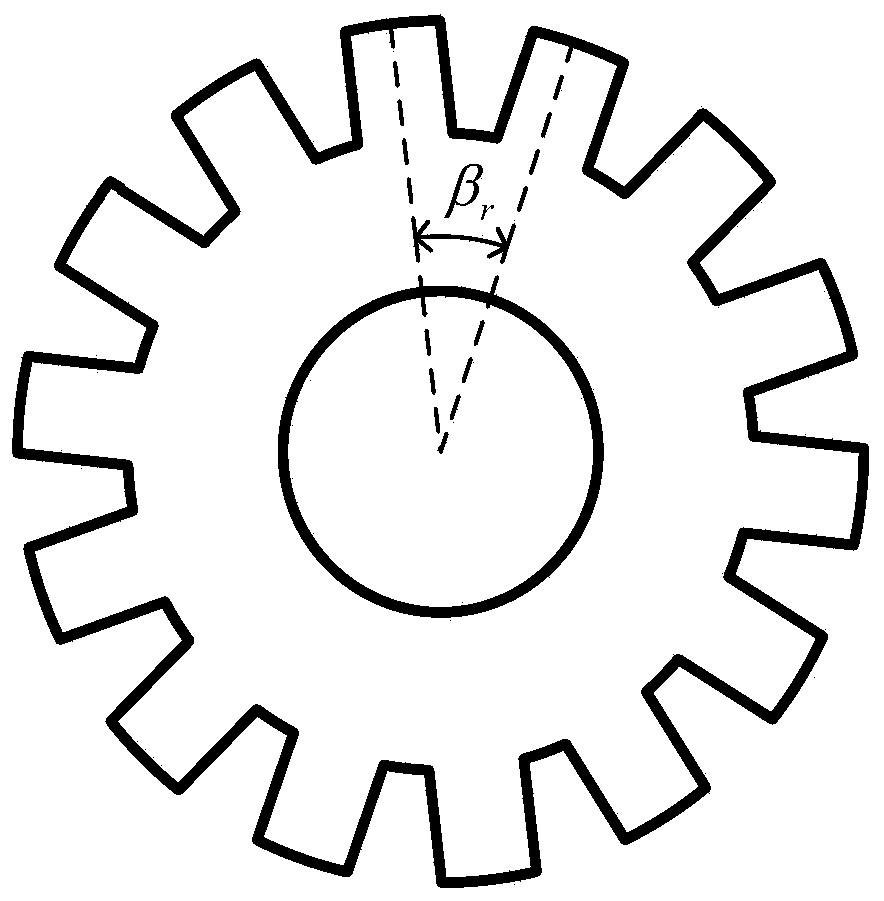

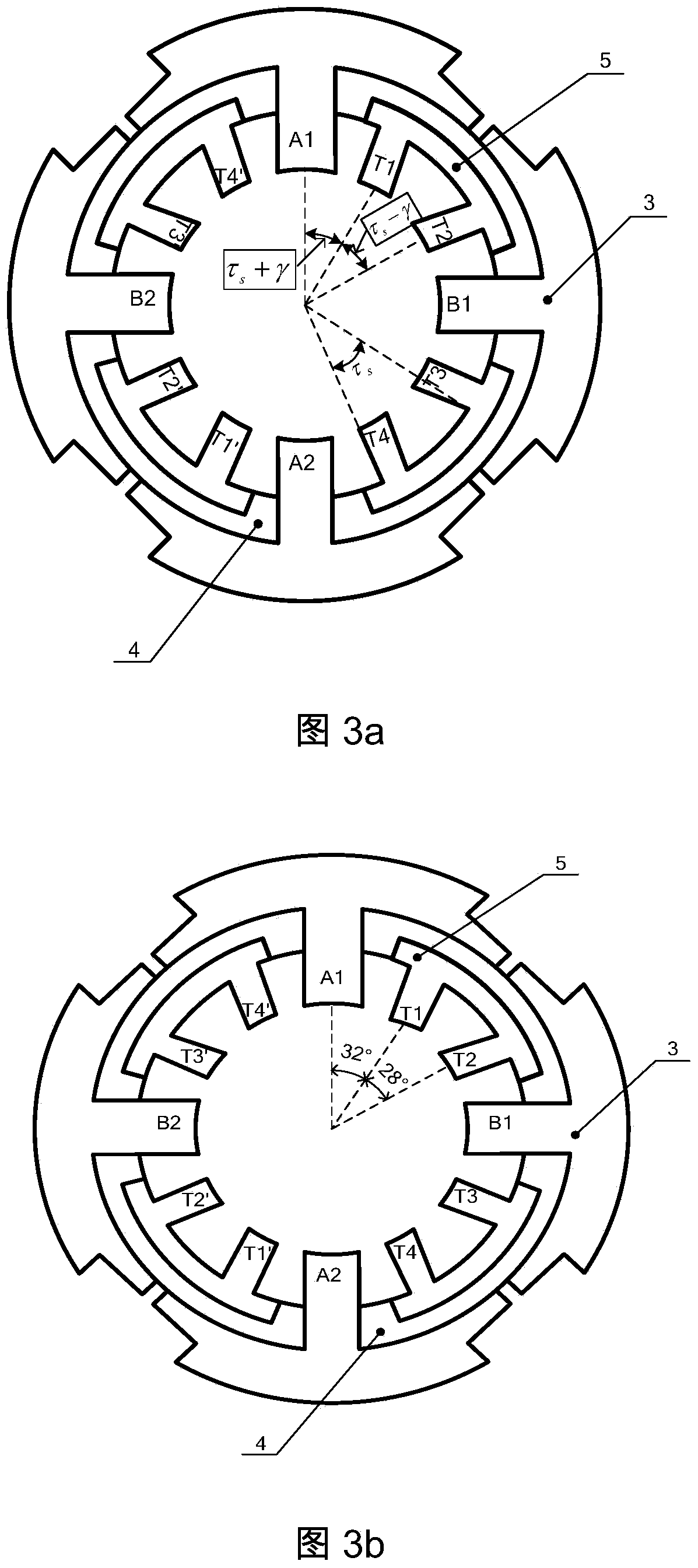

[0013] Such as figure 1 As shown, it is an axial sectional view of a 12 / 14 bearingless permanent magnet bias switched reluctance motor of the present invention, which consists of a stator back yoke 1, four permanent magnets 2, four stator suspension force cores 3, and four Magnetic isolation sleeve 4, four stator torque cores 5, one rotor core 6, one shaft 7, four suspension force winding coils 8, and eight torque winding coils 9. The stator suspension force core 3 places four stator suspension force core teeth along the +x, -x, +y, -y directions, and the suspension force winding coil 8 is wound on it; the stator torque core 5 has eight teeth in total, uniform Distributed on the circumference, and the torque winding coil 9 is wound thereon. The four permanent magnets 2 are respectively located in the slots of the stator levitation force core 3 near the stator back yoke 1 , that is, embedded between the stator levitation force core 3 and the stator back yoke 1 . The stator b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com