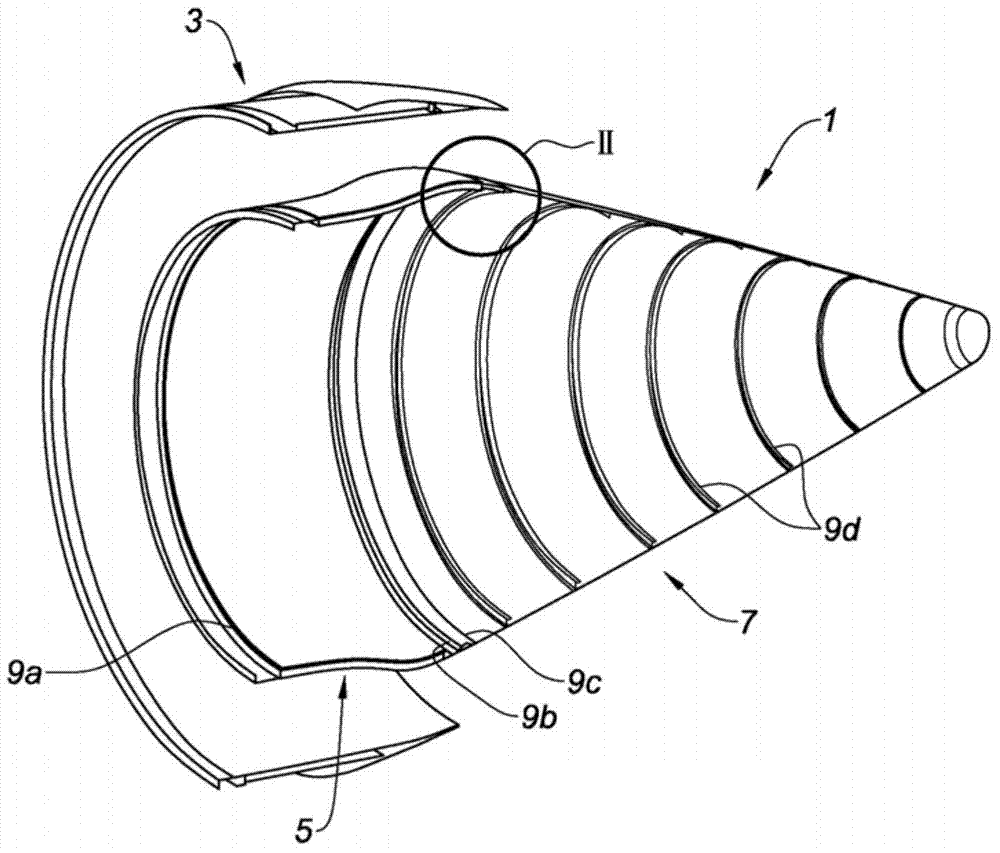

Exhaust cone for aircraft turbojet engine

A technology of turbojet and exhaust cone, applied in the direction of engine function, engine manufacturing, machine/engine, etc., can solve the problems of affecting the quality of components, high manufacturing cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

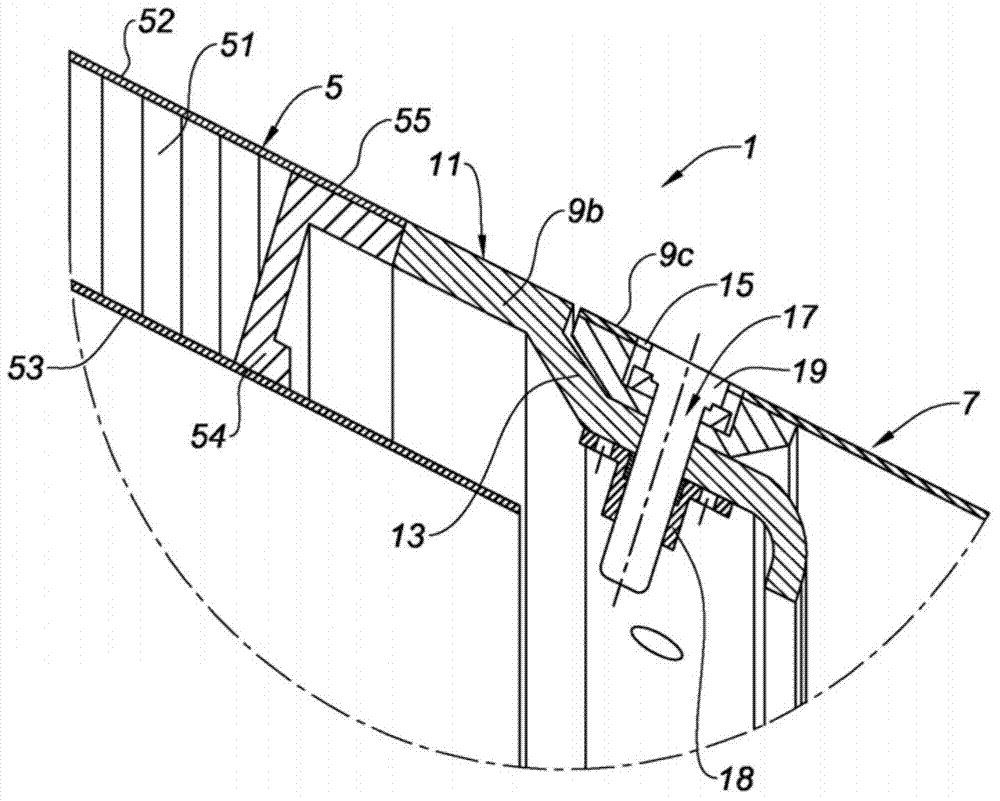

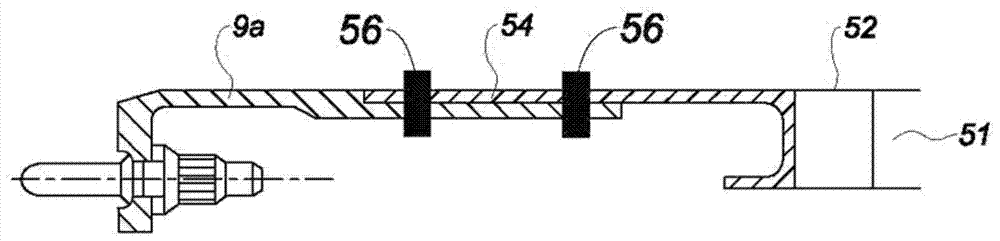

[0038] as in figure 2 shows more precisely that the front part 5 of the exhaust cone 1 is equipped with a sound-absorbing structure comprising a porous core 51, for example a honeycomb structure, formed by a perforated outer skin 52 and a solid inner skin 53. cover.

[0039] As previously described and according to the prior art, the porous core is closed by a C-shaped closure 54 also covered by an extension 55 of the outer skin 52 and by an extension of the inner skin 53 which extends Portion 55 is unperforated.

[0040] The connection between the sound-absorbing structure and the rear connecting flange 9b is provided by a C-shaped closure 54, as already explained, in particular by soldering the connection between these parts.

[0041] The flange 9b has a thickness ensuring that there is no offset (gap) from the outer skin 52 and its extension 55 in order to best provide the external aerodynamic continuity of the front cone part 5 .

[0042] Similarly, in the front part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com