Once through fan

A cross-flow fan technology, applied in the field of cross-flow fans, can solve the problem of reaching the limit of large diameter, and achieve the effects of inhibiting peeling, inhibiting deterioration and noise, and eliminating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

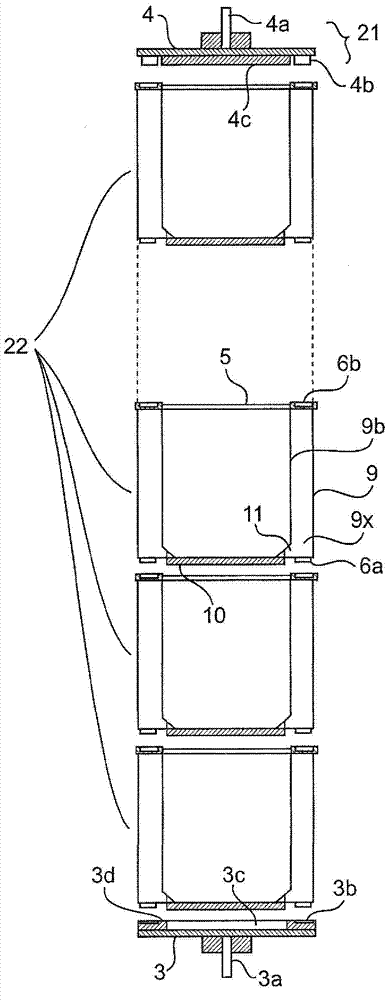

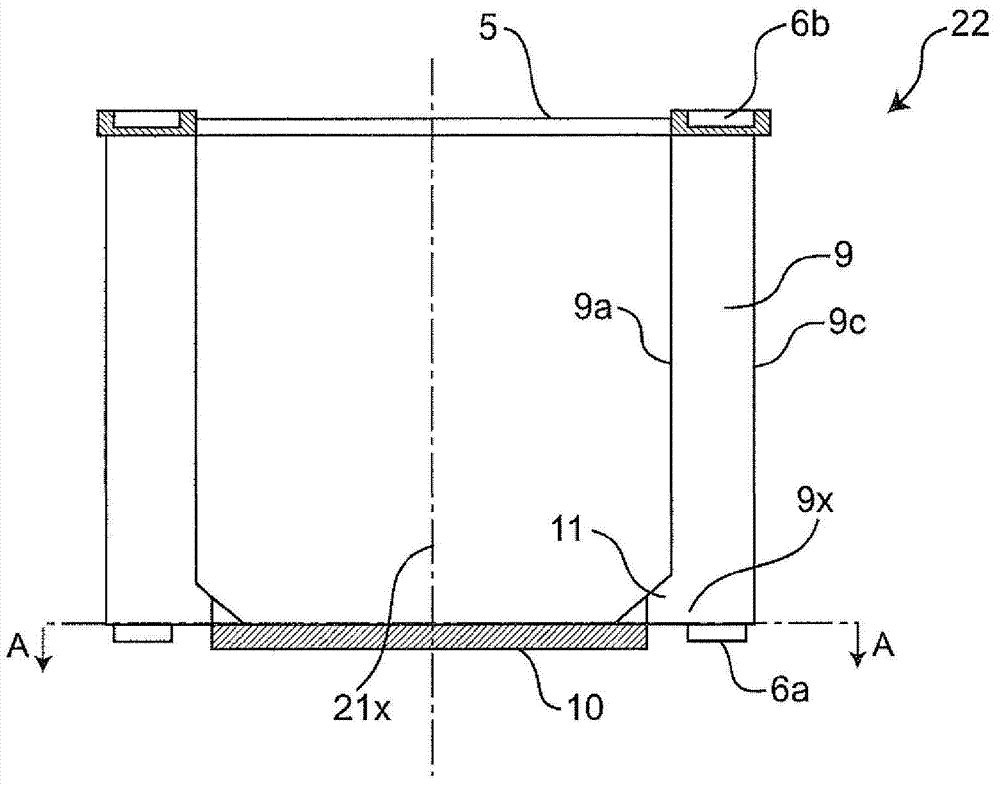

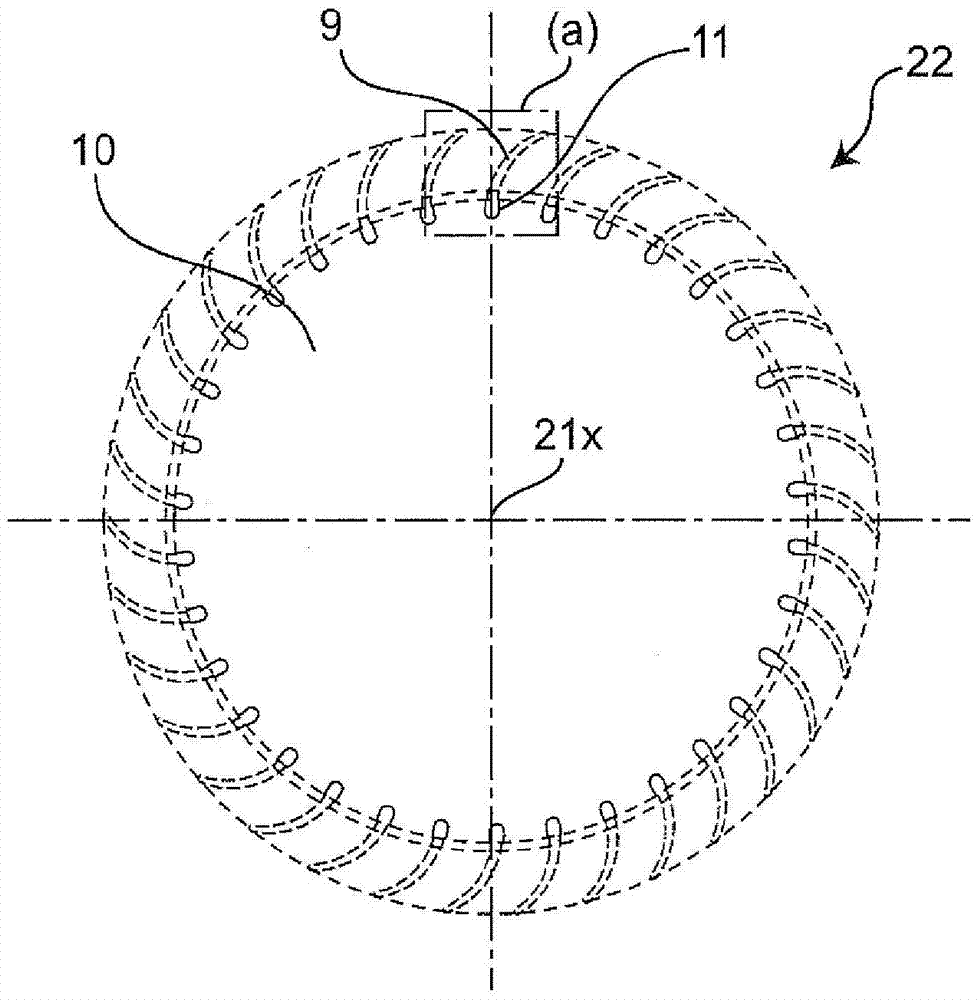

[0060] figure 1 It is an exploded cross-sectional view of the cross-flow fan according to Embodiment 1 of the present invention. figure 2 It is a cross-sectional view showing one impeller of the cross-flow fan according to the first embodiment. image 3 yes figure 2 The A-A line cross-sectional view of the cross-flow fan. Figure 4 It is a cross-sectional view of main parts showing the connecting parts of blades, protrusions, and reinforcement plates in the impeller according to the first embodiment. Figure 5 yes Figure 4 The B-B cross-sectional view of the connecting part of . In addition, for the prior art literature ( Figure 7 ~ Figure 12 ) The same structural components of the cross-flow fan are marked with the same symbols, and descriptions are omitted.

[0061] exist Figure 1 to Figure 5 Among them, the cross-flow fan 21 has an impeller 22 in which a plurality of blades 9 are arranged in an axial (rotation shaft 21 x ) direction and is connected in a cylind...

Embodiment approach 2

[0076] Image 6 It is a figure which shows the main part of the impeller 32 with which the cross-flow fan 31 which concerns on Embodiment 2 of this invention is equipped. In addition, the same code|symbol is attached|subjected to the same component as cross-flow fan 21 of Embodiment 1 mentioned above, and description is abbreviate|omitted.

[0077] Such as Image 6 As shown, the protruding length ( Image 6 The length in the left-right direction) is formed so as to gradually become smaller as it moves away from the reinforcing plate 10 in the axial direction. The axial height h of the impeller 32 of the protrusion 13 ( Image 6 The length in the vertical direction) is set within the range of 1% to 15% of the axial height H of the blade 9 (impeller 32 ) (that is, h / H=1% to 15%).

[0078] By setting the shape of the protruding portion 13 with respect to the entire impeller 32 in this way, sufficient strength for connecting the reinforcing plate 10 and the blade 9 can be ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com