Full-water-leaching washing-type gas filter

A gas filter, water immersion washing technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, combined devices, etc., can solve the problems of short contact time, increased working costs, and short bonding time, so as to save production costs and increase The effect of residence time and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

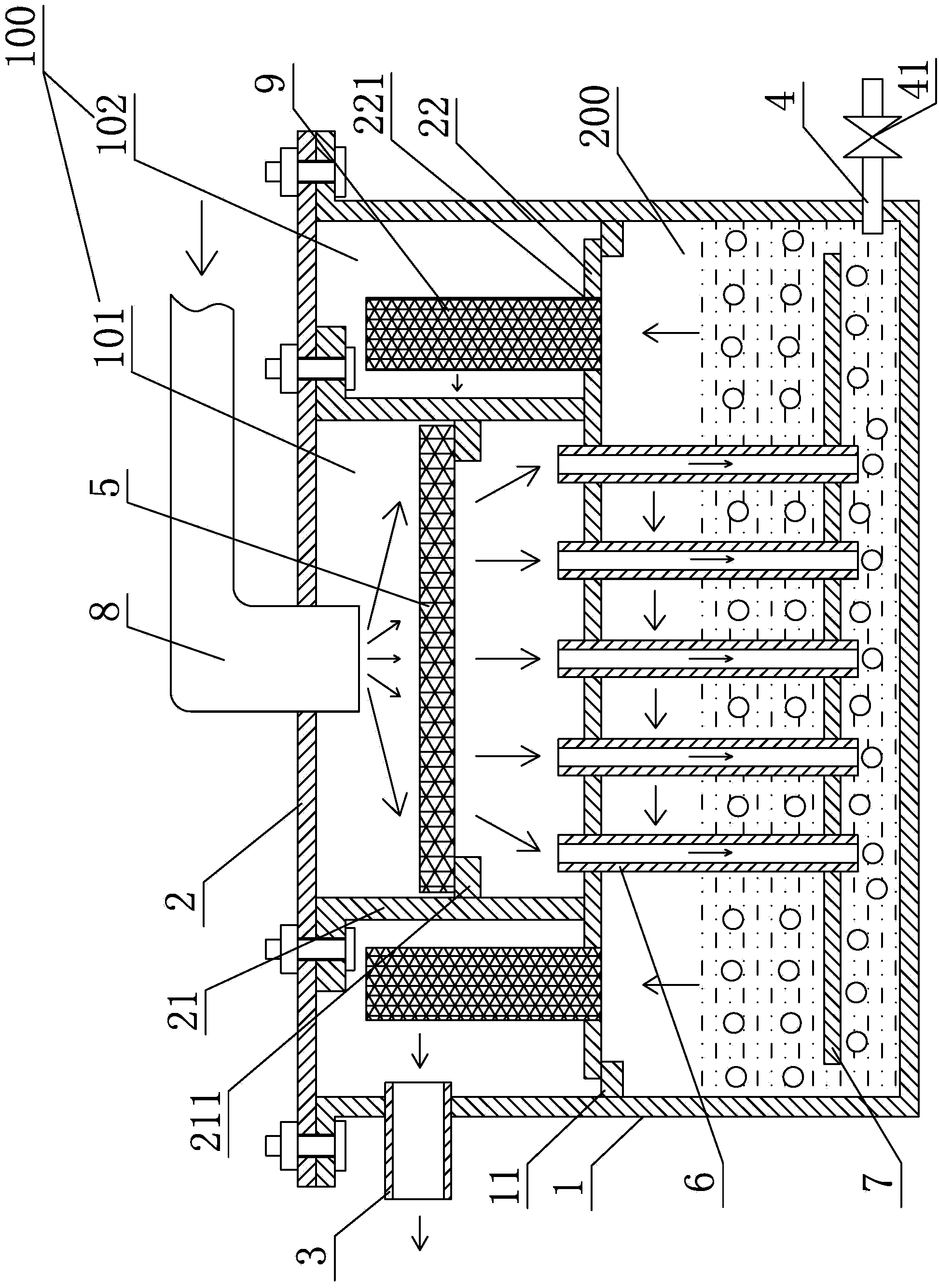

[0016] see figure 1 As shown, the fully water-immersed scrubbing gas filter includes a cylindrical body 1 and an openable cover 2 that is matched and sealed and fixed on the upper edge of the cylindrical body; the upper part of the side wall of the cylindrical body 1 is provided with an exhaust port 3. The lower part of the side wall of the cylindrical body 1 is provided with an inlet and outlet 4 for the adsorption liquid, and a limit support ring 11 is fixed on the inner side wall of the middle part of the cylindrical body 1;

[0017] The inner top wall screw of the cylinder cover 2 has a hollow cylindrical body 21, and the lower end of the cylindrical body 21 is fixedly connected with a disk 22. The disc 22 is in contact with the limit support ring 11, and the cylinder cover 2, the cylinder body 21, the disc 22 and the limit support ring 11 divide the interior of the cylinder body 1 into an upper gas filter chamber 100 and a lower gas water immersion chamber. The adsorptio...

Embodiment 2

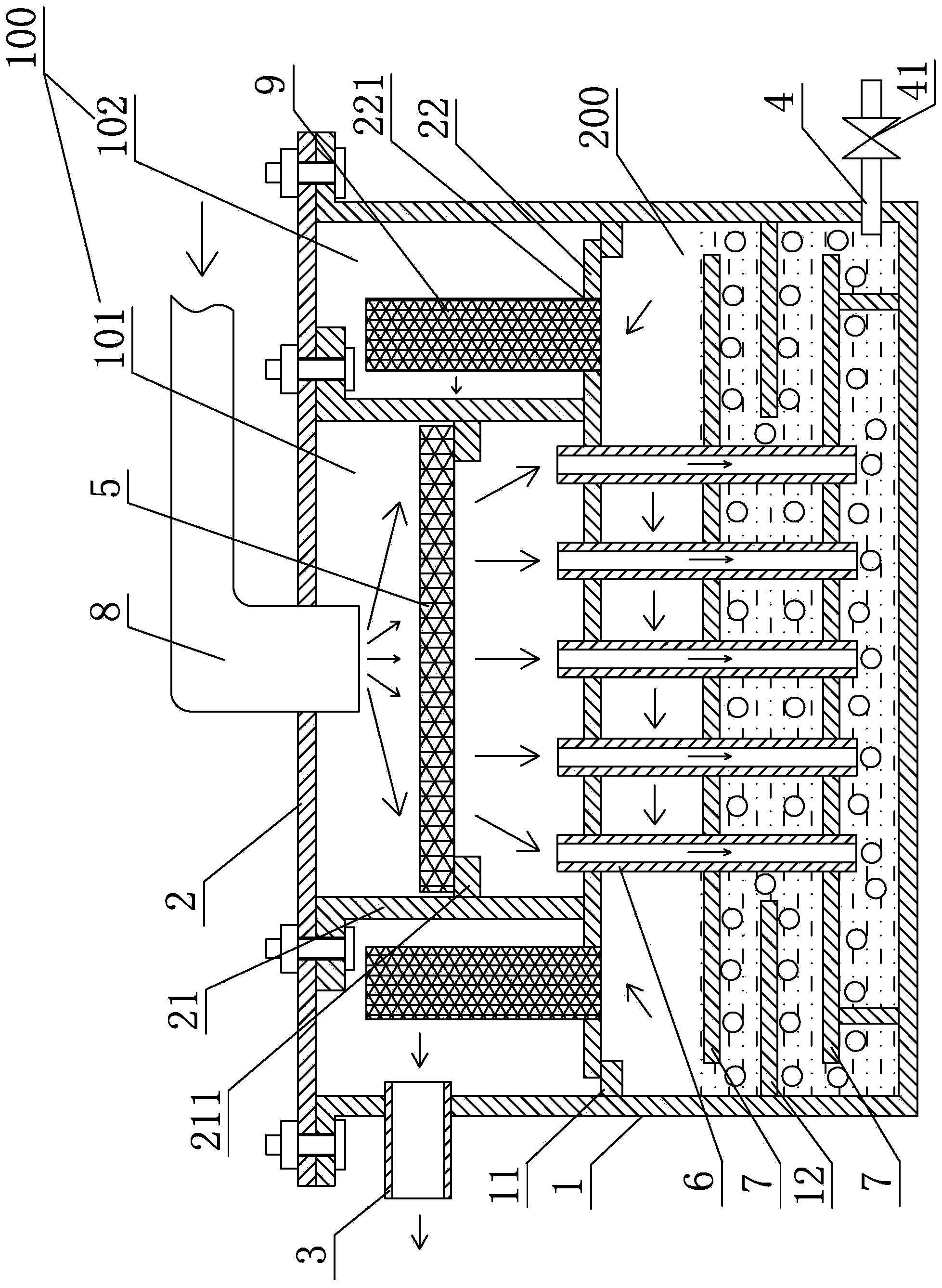

[0023] see figure 2 As shown, the full water immersion scrubbing gas filter is different from Example 1 in that the first water immersion delay adsorption disc 7 is sleeved on the outer surface of the middle part of five ventilation pipes 6, and the disc A second water immersion delay adsorption disc 7 is suspended above the inner bottom wall of the cylinder body 1, and the diameter of the second water immersion delay adsorption disc 7 is the same as that of the first water immersion delay adsorption disc 7. The time-delay adsorption disc 7 is in contact with the inner bottom wall of the cylinder body 1 through the support legs, and the second water-immersion delay adsorption disc 7 is provided with matching insertion through holes corresponding to the positions of the five ventilation pipes 6. A ventilation pipe 6 is suspended above the inner bottom wall of the cylindrical body 1 through the insertion through hole, and there is also a Water immersion delay adsorption ring 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com