Rear welding head of machine for welding edges of two sides of electronic element

A technology of electronic components and welding machines, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the assembly of small parts is not easy for manual assembly, the requirements for workers' proficiency are relatively high, and the quality and efficiency can be improved. Insufficient security and other issues, to achieve the effect of saving labor, reducing production costs, improving production efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0008] see figure 1 , the embodiment of the present invention includes:

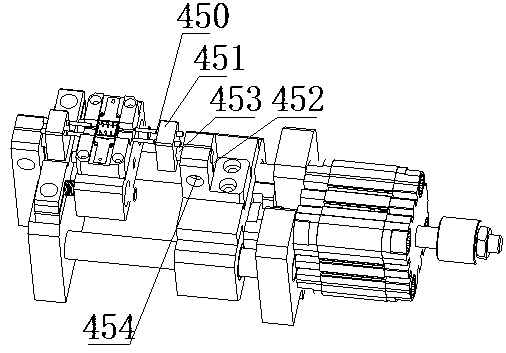

[0009] A rear welding head of a double-side leg welding machine for electronic components, the rear welding head of the double-side leg welding machine for electronic components includes a welding needle 450, a non-metallic welding needle holder 451, a welding needle support block 452, and an angle adjustment Rod 453 and adjustment screw 454, the welding needle 450 is inserted into the non-metallic welding needle holder 451, the rear side of the non-metallic welding needle holder 451 is provided with an angle adjustment rod 453, and the non-metallic welding needle holder 451 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com