Remote-control unit assembling equipment

A technology for assembling equipment and remote control, applied in the direction of assembly machine, metal processing equipment, metal processing, etc., can solve the problems of difficult to maintain product quality, low assembly effect, high labor cost, reduce the number, reduce positioning accuracy, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

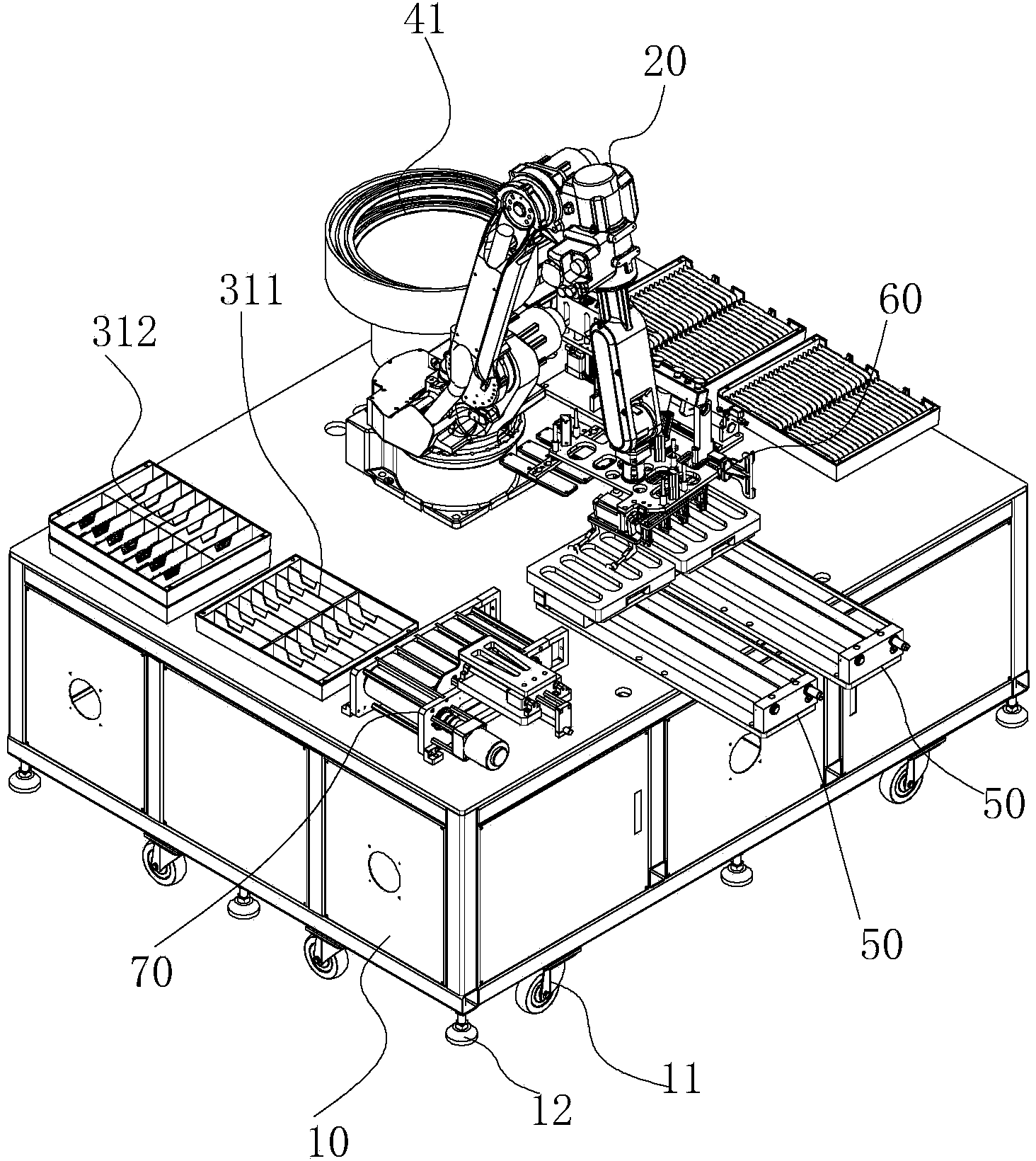

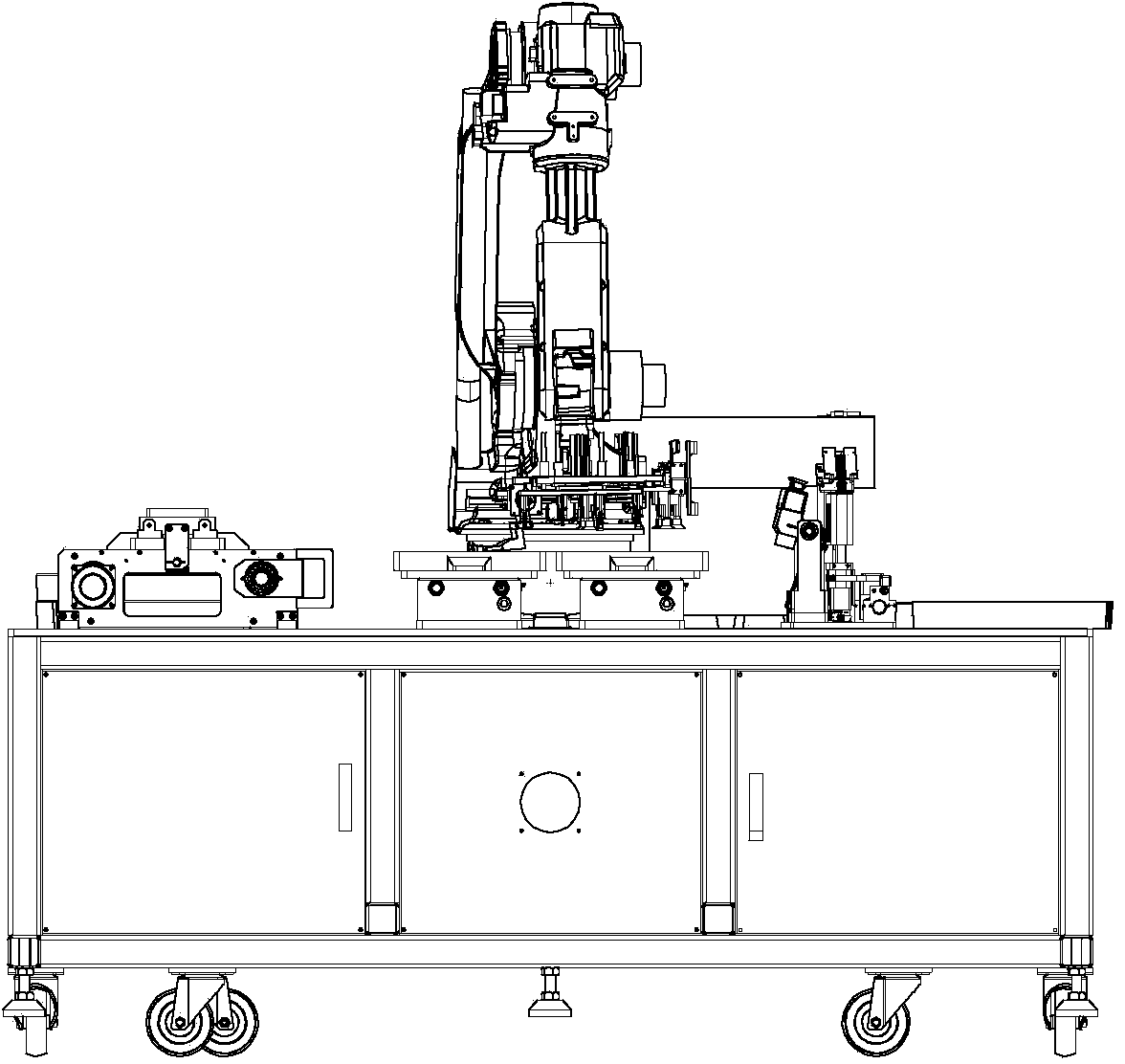

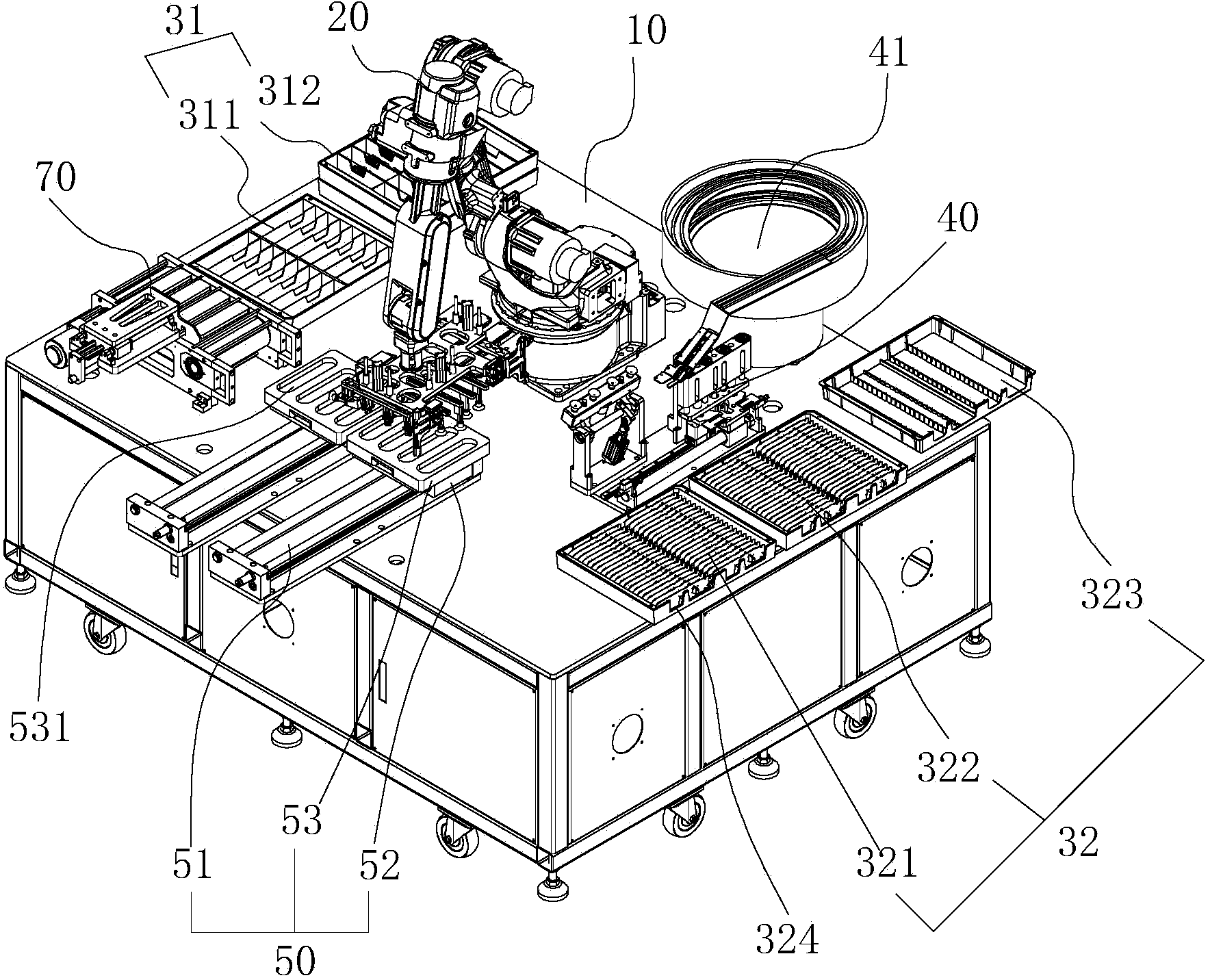

[0053] Such as Figure 1-Figure 7As shown, the remote control assembly equipment of the present invention includes a machine base 10, a robot 20 is arranged on the machine base 10, and a silica gel feeding area 31, a PCB board feeding area 32, and a direction key feeding device 40 are located on the side of the robot 20. And the treadmill mechanism 50, the treadmill mechanism 50 is provided with an assembly jig 53 for assembling the remote controller; the movable end of the robot 20 is provided with a fixture device 60 for clamping workpieces and magazines. The silica gel feeding area 31 comprises a silica gel material taking box 311, a silica gel full material box 312 and a silica gel empty material box (not shown in the figure); th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com