Automatic insertion machine

A technology of inserting machine and inserting plate, which is applied in the directions of metal processing mechanical parts, clamping and supporting, and can solve the problems of tool damage, damage and inability to use, collision of guiding mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

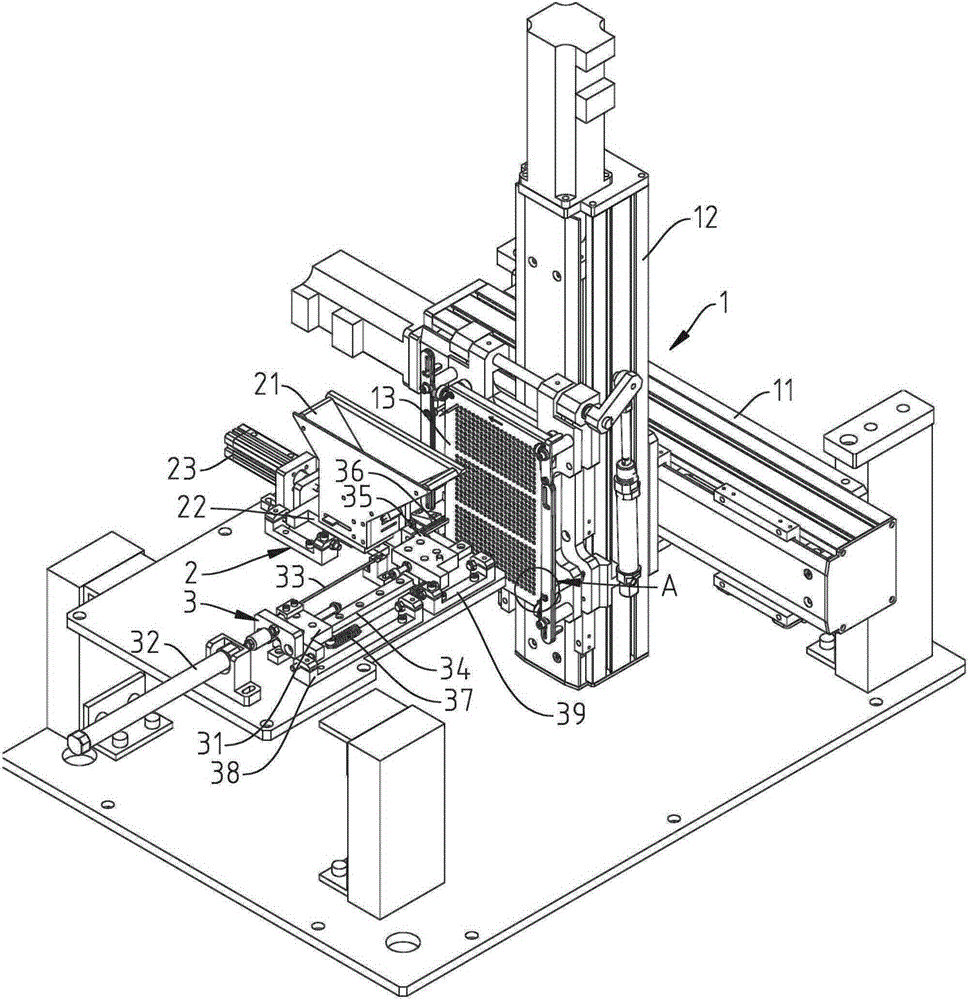

[0022] see Figure 1 to Figure 6 As shown, it can be clearly seen from the figure that the automatic disk insertion machine of the present invention is provided with a carrying device 1, a feeding device 2 and a pushing device 3, wherein:

[0023] The carrying device 1 is provided with a longitudinal displacer 11, a vertical displacer 12 is connected to the longitudinal displacer 11, and an insertion plate 13 is vertically connected to the vertical displacer 12, and a plurality of horizontal jacks are arranged on the surface of the insertion plate 13 131, so that the insertion plate 13 can be longitudinally and vertically displaced by the longitudinal displacement device 11 and the vertical displacement device 12.

[0024] The feeding device 2 is provided with a hopper 21, the hopper 21 is provided with a material placement space 211, and a material passage 212 is provided below the material placement space 211, and a plurality of forming knives 4 placed horizontally are stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com