Composite material and method for preparing same

A technology of composite materials and adhesive materials, which is applied in the field of preparation of such composite materials, can solve the problems of infeasibility, preparation cost, inventory consumption increase, etc., and achieve the effect of easy cost, durability and stability, and low tailoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

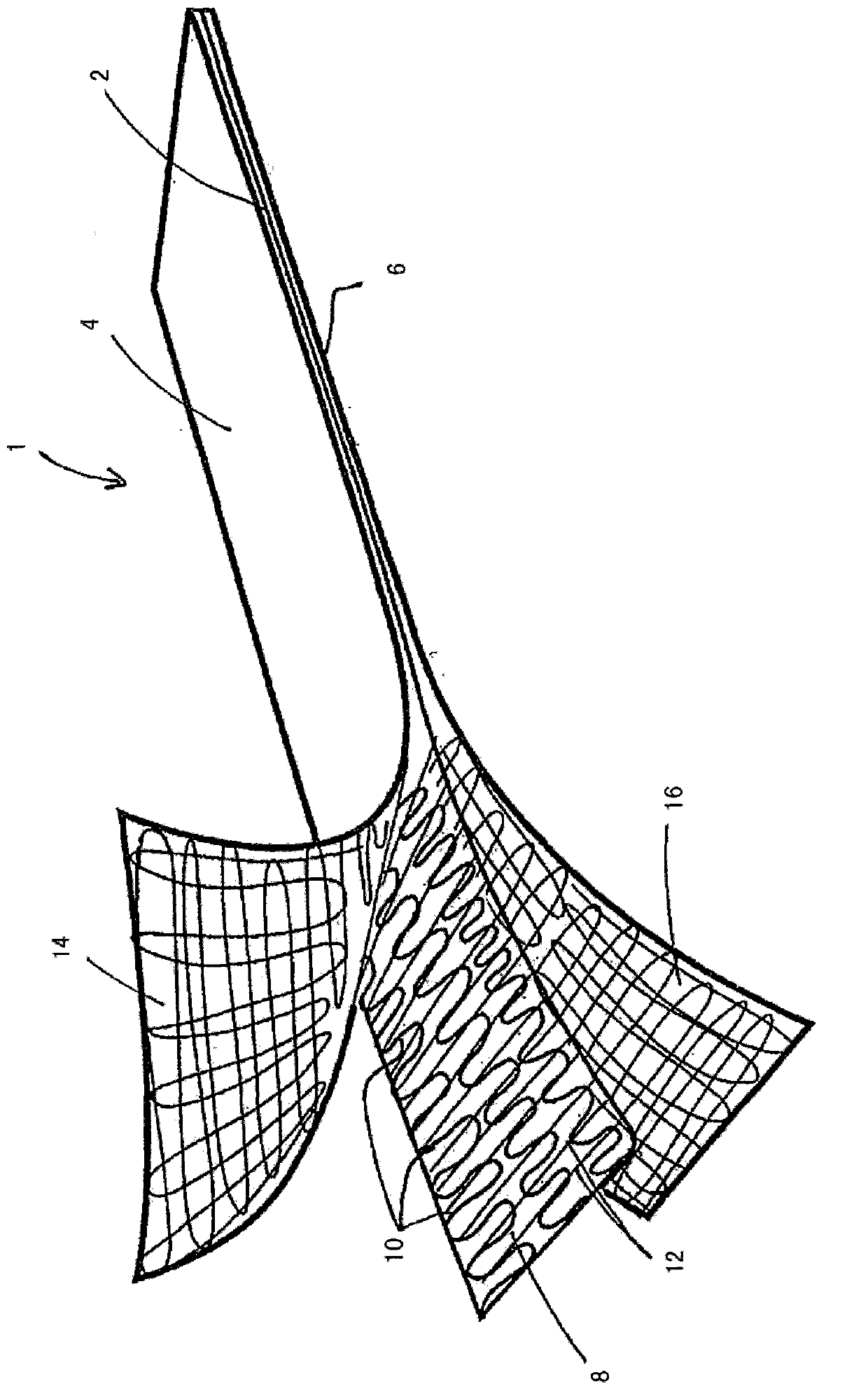

[0035] figure 1 Shown is a schematic view of a composite material 1 comprising three layers in the example shown. The first layer 2 is in the middle, at figure 1 In the embodiment shown in , this layer is covered above by a second layer 4 and below by a third layer 6 . exist figure 1 Shown in the left area of is three layers 2, 4, 6 separated from each other. The different elasticity of the materials used is shown by different hatching. The first layer 2 is made of a first material 8 which may be a film layer made of thermoplastic polyurethane, for example. figure 1 The longitudinal extension of the composite material 1 shown in is here the first direction. This is indicated by the lines 10 running corrugated in this direction in the first material 8 which is elastic in this direction. The first material 8 is inelastic in a second direction running perpendicularly to the longitudinal direction, which corresponds to the direction of the lines 12 , as indicated by the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com