Bicycle handlebar grip

A technology for bicycles and grips, which is applied to bicycle accessories, steering mechanisms, transportation and packaging, etc. It can solve problems such as poor support, hand fatigue, and poor flexibility of rubber grips, so as to improve durability, moderate hardness and friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

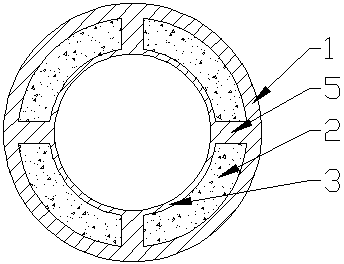

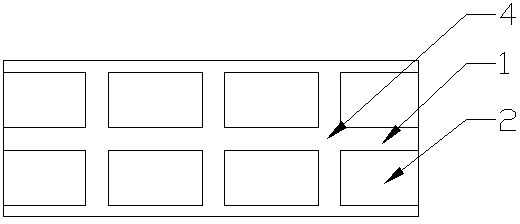

[0014] A bicycle handlebar cover, the handlebar cover comprises a sponge layer 2 and a rubber support layer 1, the rubber support layer 1 is a hollowed-out mesh, and the rubber support layer 1 is covered on the surface of the sponge layer 2.

[0015] The handle also includes a viscous fixing layer 3, the viscous fixing layer 3 is arranged on the inner wall of the sponge layer 2, and each node 4 of the hollow mesh rubber support layer 1 is provided with a connecting rib to the outer surface of the viscous fixing layer 3 5.

[0016] Half of the rubber supporting layer 1 is embedded in the sponge layer 2 in the longitudinal direction, and the other half protrudes toward the outside of the handle.

[0017] The sponge layer 2 ensures the fit and softness of the grip body to the shape of the hand. The rubber support layer 1 improves the vulnerability of the sponge itself and also improves the support performance of the grip. The setting of the connecting rib improves the grip of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com