Mechanical calcium-plastic box stacking method and device

A technology for mechanical palletizing and calcium-plastic boxes is applied in the field of mechanical palletizing methods and equipment for calcium-plastic boxes, and achieves the effects of stable operation and reduced labor intensity of palletizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Embodiments of the present invention are further described in conjunction with the accompanying drawings:

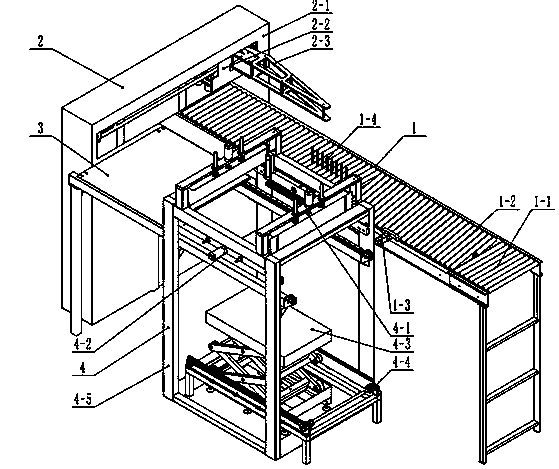

[0071] The present invention includes a conveying device 1 , a transfer device 2 , a layer transfer device 3 and a palletizing device 4 . For each device, its composition and working principle are explained separately.

[0072] 1. Conveying device

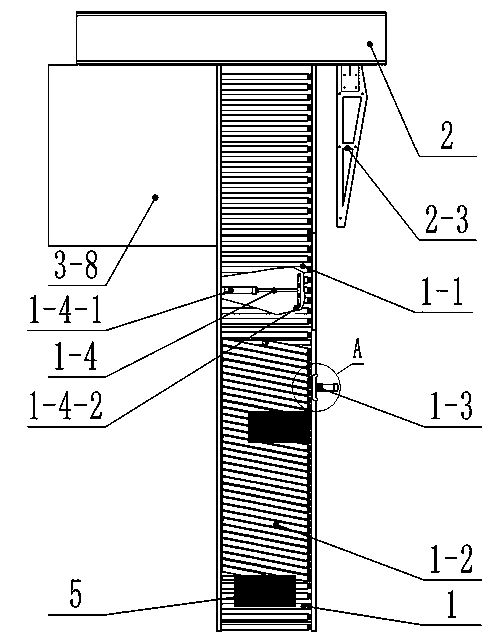

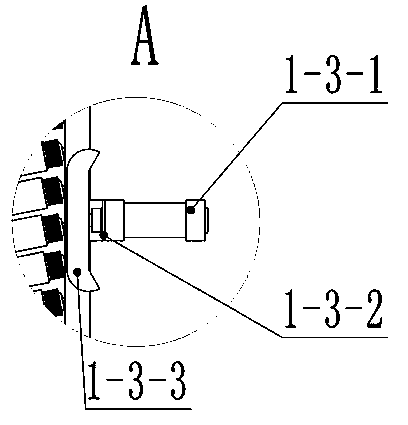

[0073] Such as figure 1 The overall structure diagram of the equipment, figure 2 Conveyors and transfer devices, image 3 Schematic diagram of the steering mechanism, Figure 4 The schematic diagram of the transfer device is shown:

[0074] The function of the conveying device 1 is to transport the calcium-plastic boxes 5 packaged by the production line, sort them aside and straighten them, and buffer the calcium-plastic boxes in a specific arrangement. The delivery device is made up of a delivery mechanism 1-1, a side-by-side mechanism 1-2, a steering mechanism 1-3 and a case-pushing mechanism 1-4. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com