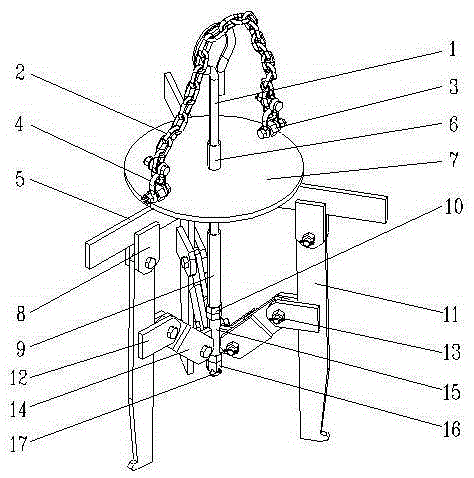

Three-fork connecting rod self-adjusting coil spreader

A self-adjusting, trident technology, applied in the field of spreaders, can solve problems such as limited weight of hoisted objects, potential safety hazards, and limited manpower, and achieve the effects of improving work efficiency and safety factor, reducing labor intensity, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

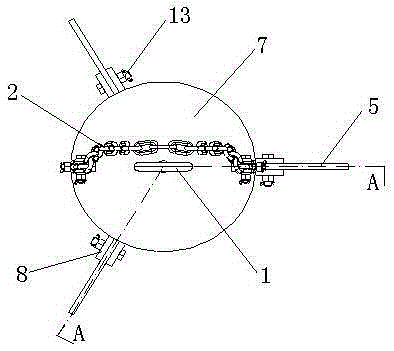

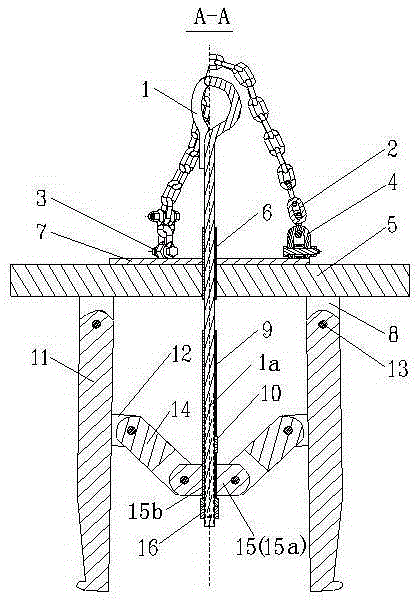

[0014] Example: A preferred embodiment of the present invention is as follows, the self-adjusting coil spreader of the tripod link, such as figure 1 , figure 2 and image 3 , the hanging lugs 3 are symmetrically welded on the top of the hanging plate 7, the lifting chain 2 is connected to the hanging lugs 3 through two sets of D-shaped shackles 4, and the first fixed connection arm 8 on the hanging plate 7 and the support arm 5 is formed. On the balance structure, the three suspension arms 11 are connected by bolts 13, and the circular screw rod 1 passes through the guide tube 6 on the hanging plate 7 at the center position of the balance structure. like Figure 4 , the screw body of the ring screw 1 is equipped with a movable limit sleeve 9 and a trident connecting arm sleeve 15. The trident connecting arm sleeve 15 is composed of three connecting lugs 15a uniformly welded on the outside of the sleeve 15b. The movable limit sleeve 9 Two adjusting nuts 10 are installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com