Discharging device for injection molding of plastic bracket of camera module

A camera module and plastic technology, which is applied to the field of injection and blanking devices for plastic brackets of camera modules, can solve the problems of high production cost and low work efficiency, and achieve the effect of improving work efficiency and safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

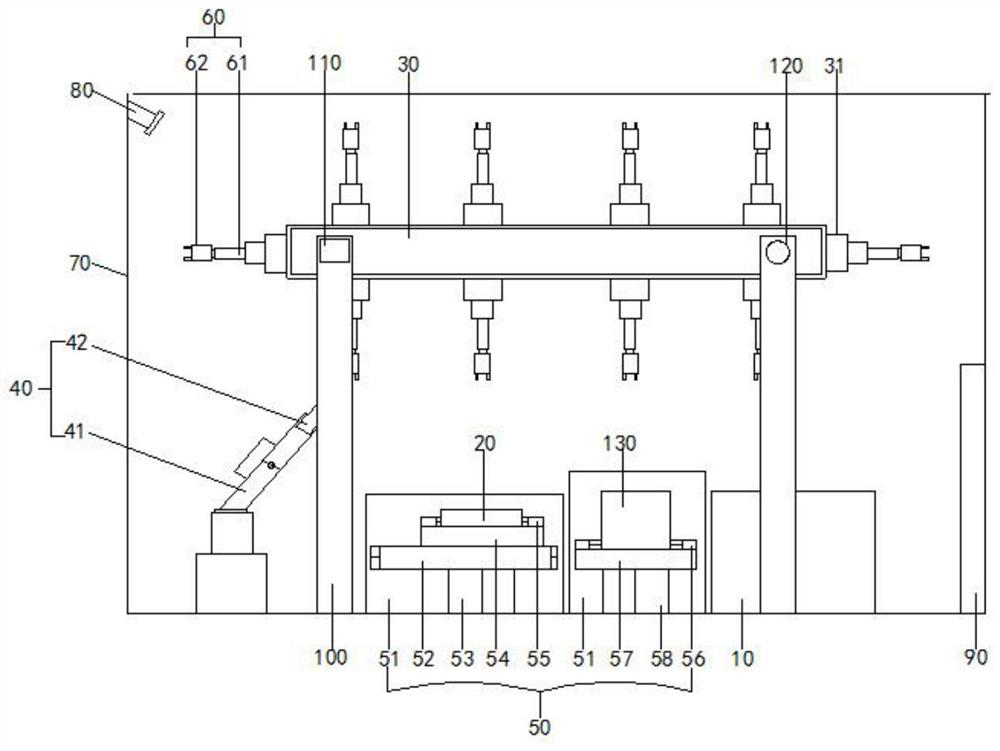

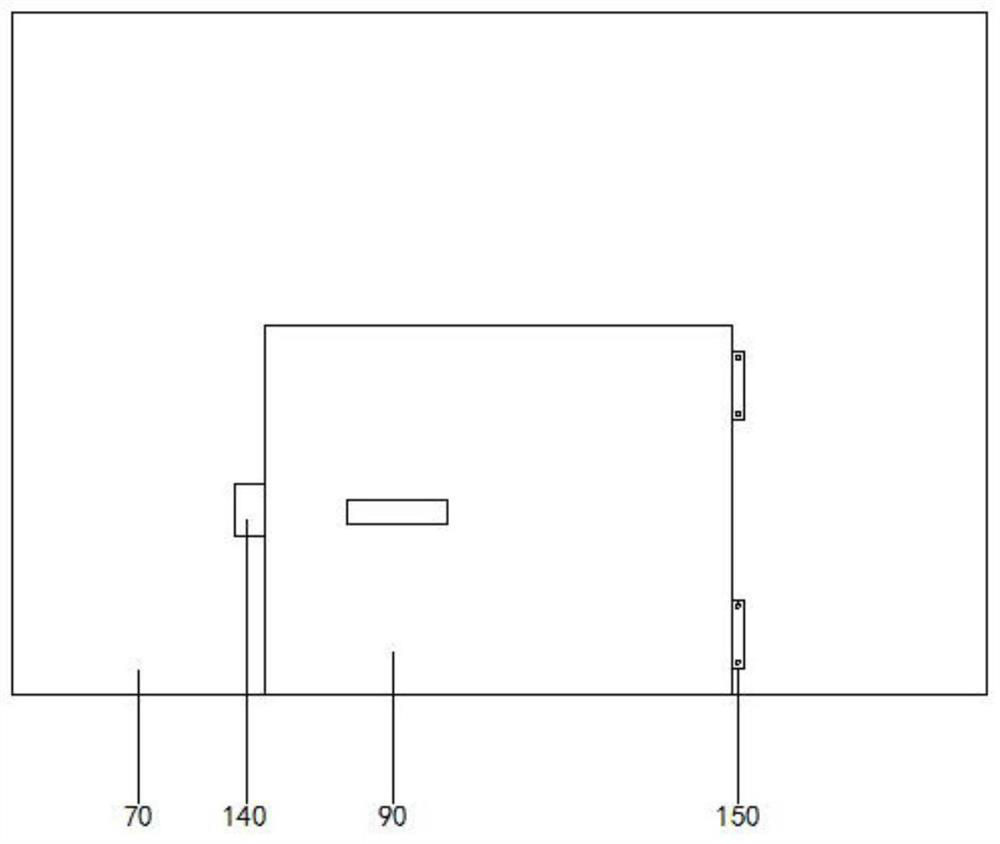

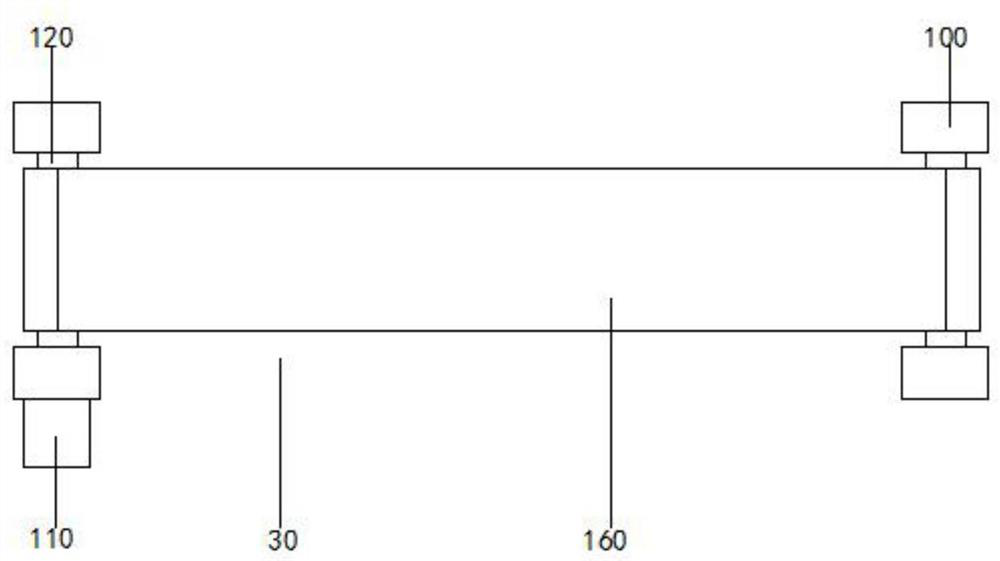

[0020] refer to Figure 1-3 , a camera module plastic bracket injection molding blanking device, including an injection molding machine 10, also includes a product receiving mechanism 50, a circular conveying line 30, a CCD detection mechanism 40, a safety protection mechanism and a plurality of gripping manipulators 60, and a circular conveying line One side of the injection molding machine is erected on the top of the injection molding machine and a distance is left between the injection molding machine. A plurality of follower blocks 31 are equidistantly installed on the circulating conveying line, and a plurality of grabbing manipulators are correspondingly installed on a plurality of follower blocks. During the operation, the circular conveying line can continuously drive multiple manipulators above the injection molding machine. At this time, multiple grasping manipulators can successively grab a camera module plastic bracket from the mold. The CCD detection mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com