Rotary feeding mechanism of battery liquid-filling machine

A technology of rotary feeding and liquid injection machine, applied in battery pack components, circuits, electrical components, etc., can solve problems such as slow efficiency, hidden dangers, battery capacity reduction, etc., to reduce production costs, ensure quality, and improve work. The effect of efficiency and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

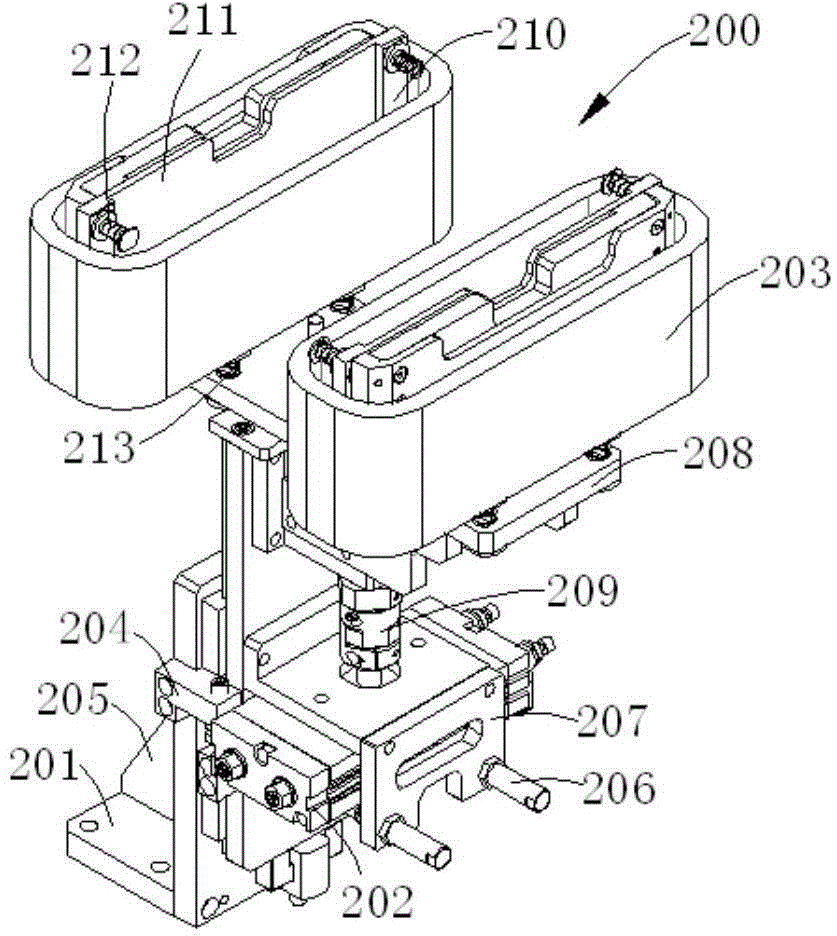

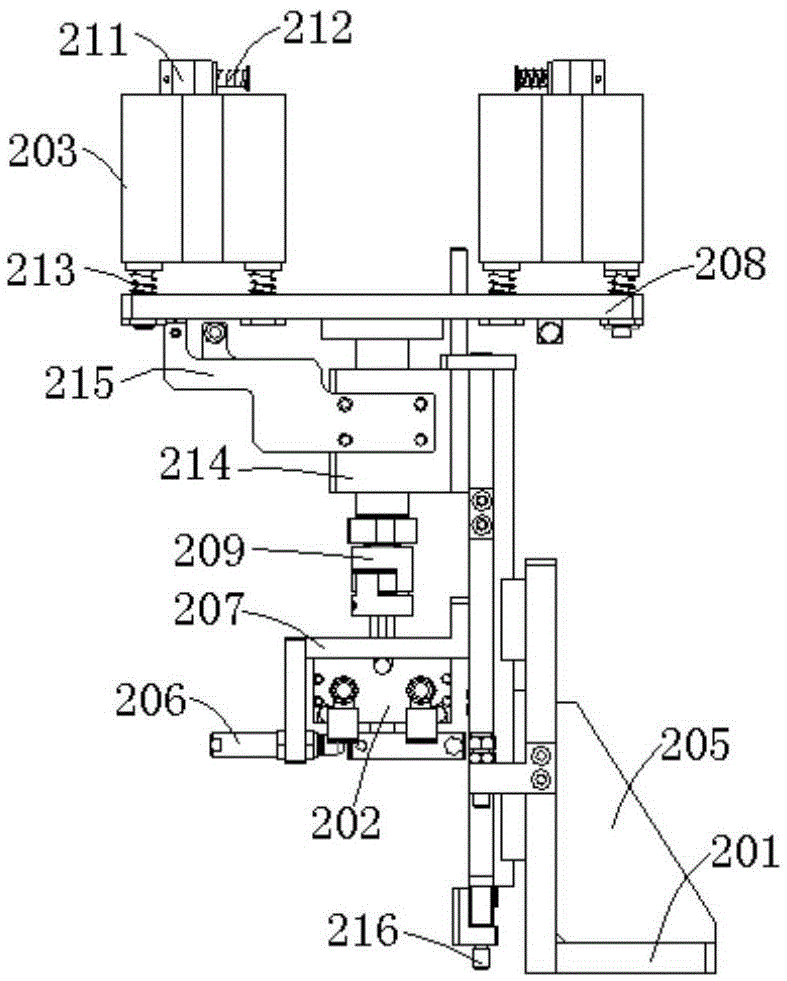

[0023] A rotary feeding mechanism 200 of a battery liquid injection machine disclosed in the present invention is used to realize automatic charging of batteries during the process of injecting electrolyte solution into the batteries. combine figure 1 and figure 2 As shown, the rotary feeding mechanism 200 of the battery liquid injection machine of the present invention includes a base 201, a rotary driving member 202, a plurality of loading parts 203 and a limit block 204. The base 201 is used to support the entire feeding mechanism. Reinforcing ribs 205 are fixedly arranged to strengthen the supporting strength of the base 201 . The rotary driving part 202 is fixedly installed on the base 201 and is used to drive the loading part 203 to go up, down and rotate. The rotary driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com