Reinforcing steel bar structure of hinge joint

A technology of steel bars and hinged joints, which is applied in the field of steel-concrete composite structures, can solve problems such as poor tensile strength, poor shear resistance, and easy damage to hinged joints, so as to improve shear resistance, prevent mutual separation, and improve connection performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

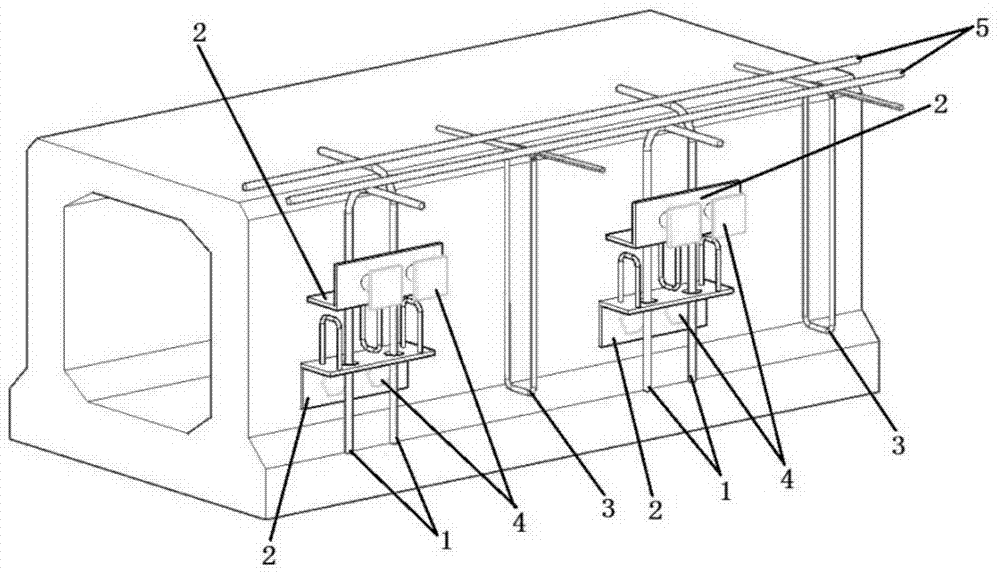

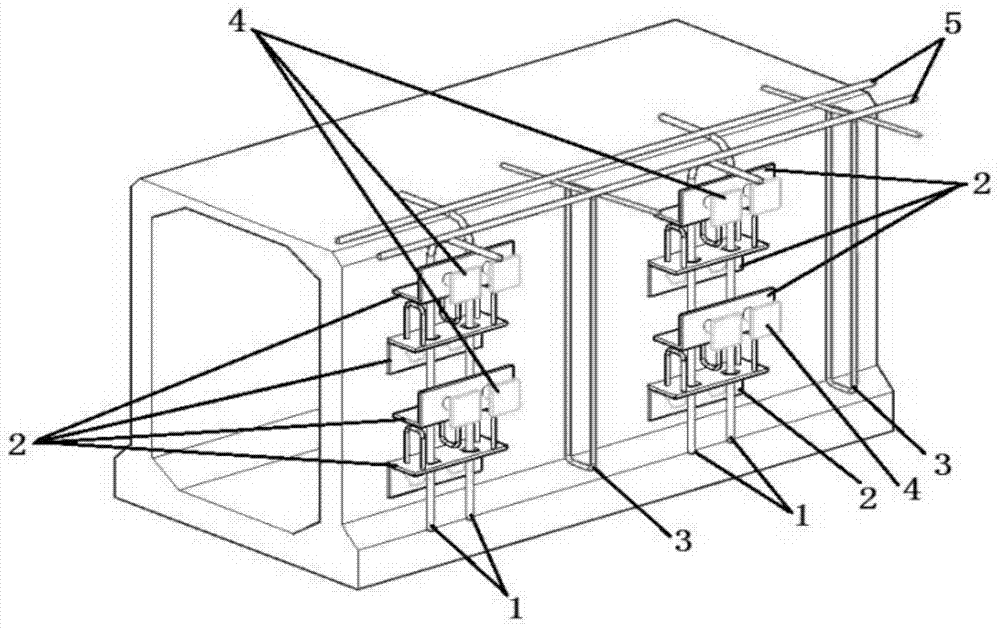

[0021] Example: such as figure 2 As shown, there are two restraint structures, one restraint structure includes two pairs of folded plates 2 and two restraint reinforcement bars 1, and there are four pairs of folded plates 2 in total.

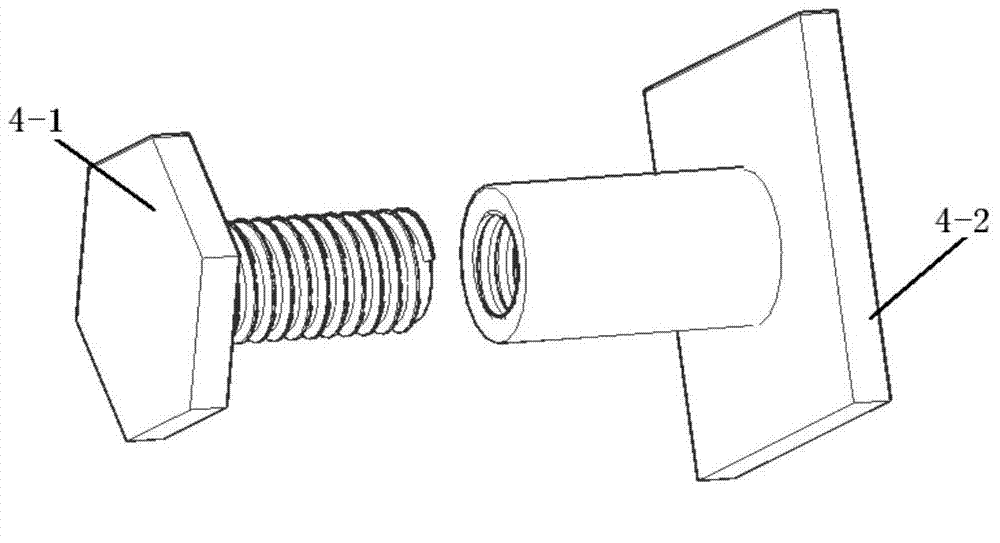

[0022] The folding plate 2 is as Figure 4 As shown, there are L=2 restraining steel bar holes 2-2 on a folding surface of the folding plate 2, and three reinforcing bars 2-1 are arranged between the opposite folding surfaces of every pair of folding plates 2, and the two reinforcing bars 2-1 of each pair of folding plates 2 The ends are welded on the same folding surface and the steel bar 2-1 and the folding surface form a closed geometric shape, and a pair of opposite restraint reinforcement holes 2-2 are separated between adjacent closed geometric shapes, and the adjacent closed geometric shapes The steel bars 2-1 are respectively welded on the opposite folding surfaces, that is, one is welded on one folding surface, and two are welded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com