Method for improving compression resistance bearing capacity of concrete prefabricated hollow pile

A technology of concrete and hollow piles, which is applied in the direction of sheet pile walls, foundation structure tests, construction, etc., can solve the problems of insufficient compressive bearing capacity of concrete prefabricated hollow piles, and achieve the effect of saving engineering cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

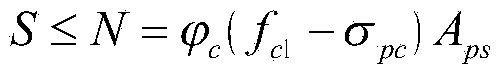

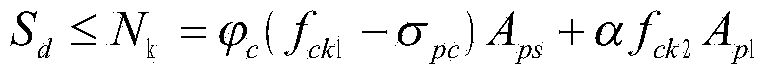

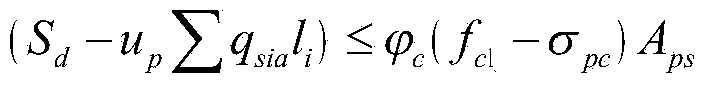

[0019] (1) Carry out the preliminary design of the upper structure according to the architectural design drawings, and determine the pile type of the precast concrete hollow pile according to the calculation results and the geological survey report; when designing the concrete prefabricated hollow pile, the impact of core filling is not considered, and the design value of its compressive bearing capacity Satisfy:

[0020]

[0021] In the formula, S is the basic combination of load effects transmitted to the top of the pile, N is the design value of the compressive bearing capacity of the pile body, is the pile-forming process coefficient of the foundation pile, f c1 is the design value of axial compressive strength of pile concrete, σ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com