Firework barrel blocking piece punching and tamping method and device

A cannon barrel and punching technology is applied in the field of a firework barrel blocking piece punching and filling method and device, which can solve the problems of low production efficiency, high labor cost and high equipment cost, and achieves improved production efficiency, reduced labor intensity, The effect of saving equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

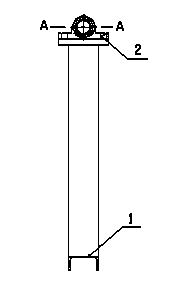

[0031] The present invention will be further described below in conjunction with accompanying drawing.

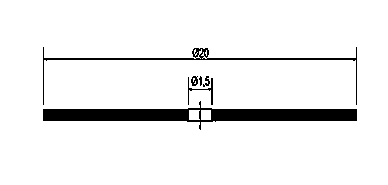

[0032] It can be seen from the accompanying drawings that the present invention relates to a blanking and filling method for the blocking piece of a fireworks barrel, which adopts automatic coil feeding, and combines the blanking mechanism and the filling and pressing mechanism to form a combined blanking and filling mechanism. , and the blanking and filling mechanism is arranged on one side of the punching mechanism; after the coil is punched, the automatic feeding of the coil is used to send the punched part into the blanking and filling mechanism for blanking and filling; Push the blocking piece and press it into the hole of the corresponding gun barrel.

[0033] The method for blanking and pressing the plugging piece of the fireworks barrel comprises the following steps:

[0034]A. Feeding: Install and debug the blanking and filling device of the fireworks barrel, plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com