Method for determining gas content in hardened concrete

A technology of concrete and air content, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of hardened concrete that has not been studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

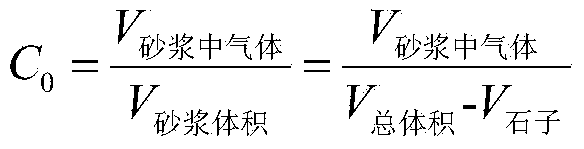

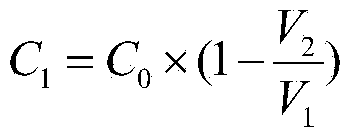

Method used

Image

Examples

Embodiment Construction

[0021] Guangxi China Resources Cement was used to prepare concrete with medium sand (river sand) provided by Beijing Fuwei Commercial Center as fine aggregate and mountain stone as coarse aggregate.

[0022] Sample preparation

[0023] (1) Prepare a group of concrete samples, the size of the test block is 10cm×10cm×10cm, every 3 samples are a group, and the samples are obtained after 28 days of curing in a standard curing box.

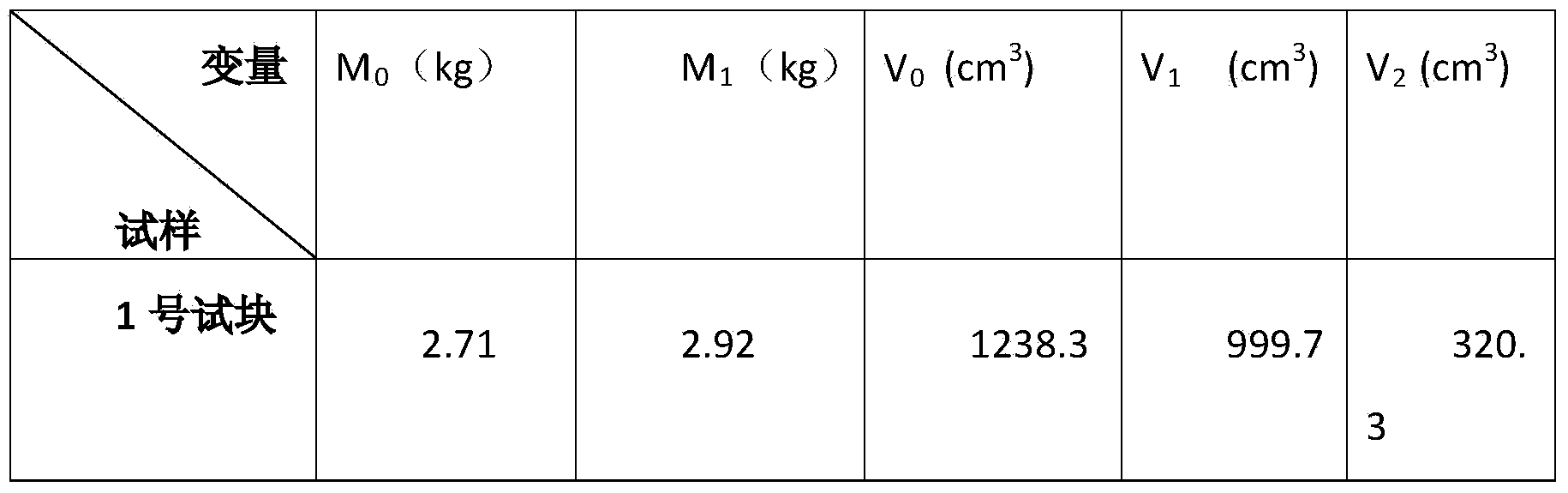

[0024] (2) Dry the cured concrete sample in a drying oven at 105-110°C to constant weight, and measure its mass as M 0 , put the concrete into the melted wax until its surface is covered with paraffin, take it out after the paraffin solidifies, and weigh its mass M 1 , and then use the drainage method to measure the volume V of the surface-wrapped paraffin concrete 0 .

[0025] (3) Strip off the paraffin on the concrete surface, make the surface clear and clean, crush it with a jaw crusher, take 3 to 5 mortar samples with the size of soybean particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com