A vacuum maintenance system for high-purity germanium detectors with thermal purification function

A high-purity germanium detector and maintenance system technology, which is applied in the field of maintenance system for high-purity germanium detector vacuum faults, can solve the problems of no signal output, poor energy resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

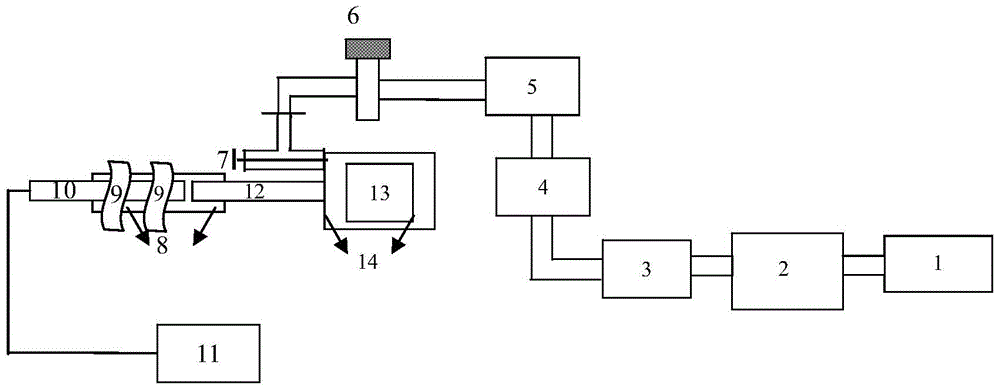

[0051] A vacuum maintenance system for HPGe detectors with heat purification function is composed of two units: vacuum maintenance and heat purification.

[0052] The vacuum maintenance unit is composed of a front-stage mechanical pump 1, a molecular sieve adsorption trap 2, a molecular pump 3, a high-vacuum pneumatic flapper valve 4, a digital display composite vacuum gauge 5, a valve 6, and a vacuum interface valve 7. Among them, mechanical pump 1, molecular pump 3, digital display composite vacuum gauge 5, and valve 6 are the necessary components of the vacuum maintenance unit; molecular sieve adsorption trap 2, high vacuum pneumatic plug valve 4, and vacuum interface valve 7 are used to avoid HPGe detection It is a necessary component added to protect the germanium crystal from artificial damage and realize the vacuum maintenance function of the crystal.

[0053] If the system has a power outage and is unattended during the long-term maintenance and purification process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com