Strongly polar mesoporous adsorbent for wind power gear oil regeneration and preparation method thereof

A gear oil, strong polarity technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problem of large pressure difference in oil regeneration filter, low efficiency of removing aging products, and low diffusion rate of active centers to reduce the acid value of oil, improve the removal of sludge, and restore performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

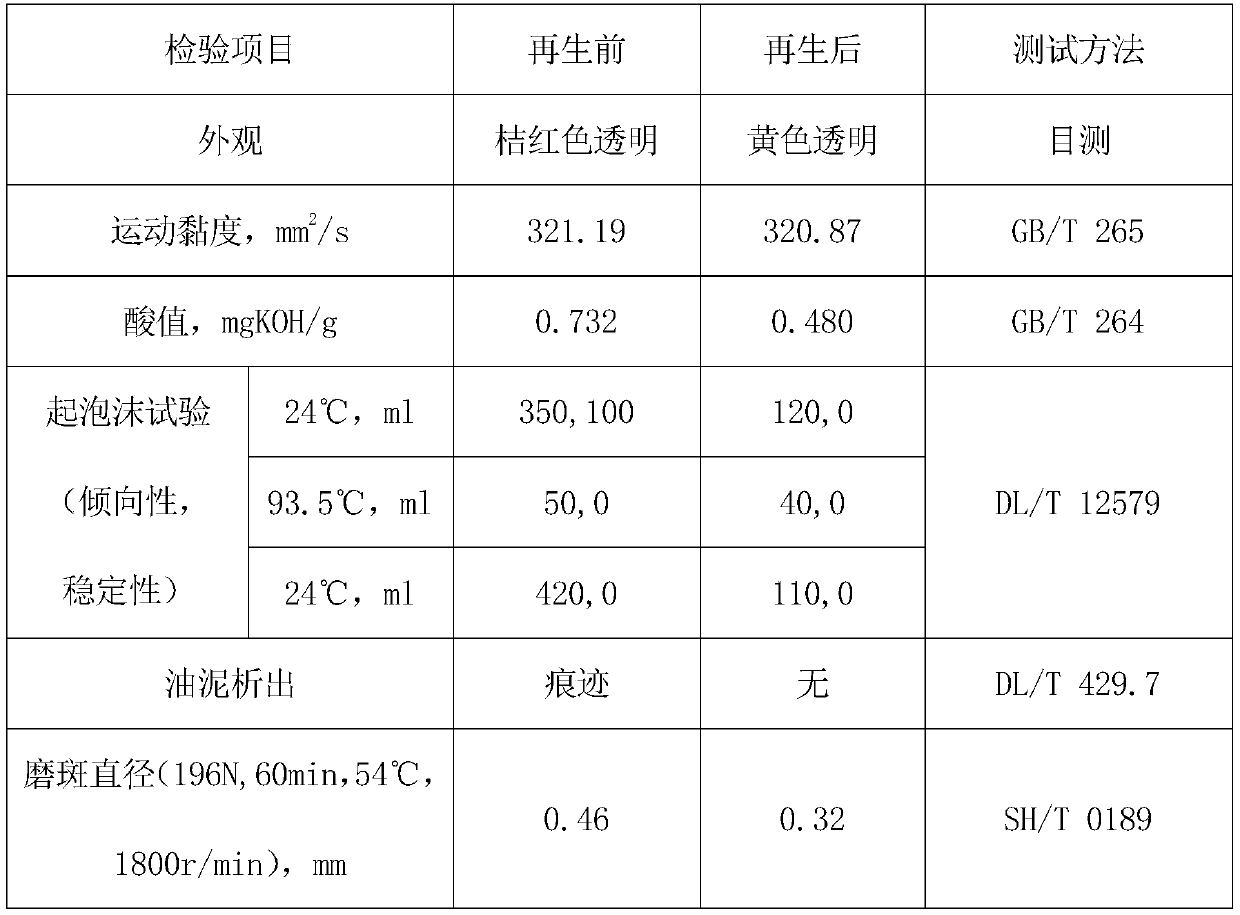

Embodiment 1

[0032] Dissolve 6g of ethylenediamine and 100g of cetyltrimethylammonium bromide in 500g of distilled water, adjust the pH value to 8.5 with ammonia water and glacial acetic acid, stir in a water bath at 65°C for 5 hours, and set the stirring speed to 800r / Min, add 15g of water-soluble styrene-acrylic emulsion and 20g of acrylic emulsion and continue to stir for 4 hours, then add 0.8g of powder with a particle size of about 10nm prepared by carbon nanotubes, continue to stir for 4 hours, and then add 300g of anhydrous sodium silicate , a mixture of 250g of triisobutylaluminum and 170g of butyl titanate was added, the stirring speed was set to 1300r / min and continued stirring for 10 hours, cooled at room temperature, and the resulting white initial gel product was placed in a 95°C blast oven After drying for 15 hours, the obtained white solid powder was washed three times with absolute ethanol and distilled water respectively, and the washing solution was colorless and transpar...

Embodiment 2

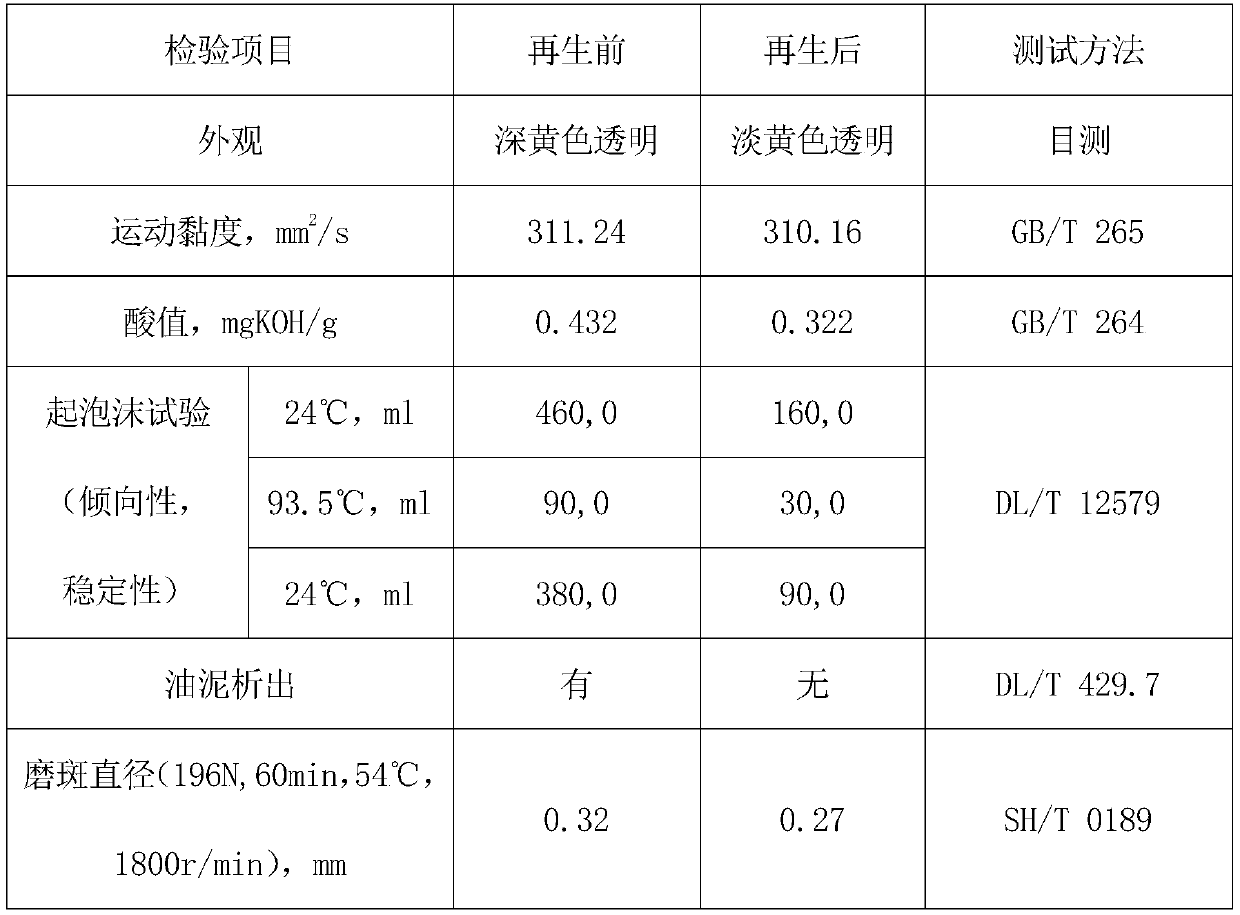

[0037]Dissolve 8 g of dipropylamine, 16 g of formamide, and 100 g of cetyltrimethylammonium bromide in 500 g of distilled water, adjust the pH value to 9.6 with ammonia water and glacial acetic acid, stir in a water bath at 55°C for 5 hours, and stir Set the speed at 800r / min, add 10g of water-soluble ethylene copolymer emulsion and 5g of acrylic acid emulsion and continue to stir for 6 hours, then add 1.5g of powder with a particle size of about 10nm prepared by carbon nanotubes, continue to stir for 3 hours, and then mix 160g Add a mixture of silica sol, 190g sodium metaaluminate and 120g isopropyl titanate, set the stirring speed to 1500r / min and continue stirring for 14 hours, cool at room temperature, and place the obtained white initial gel product at 105°C for air blowing After drying in an oven for 18 hours, the obtained white solid powder was washed three times with absolute ethanol and distilled water respectively, and the washing solution was colorless and transparen...

Embodiment 3

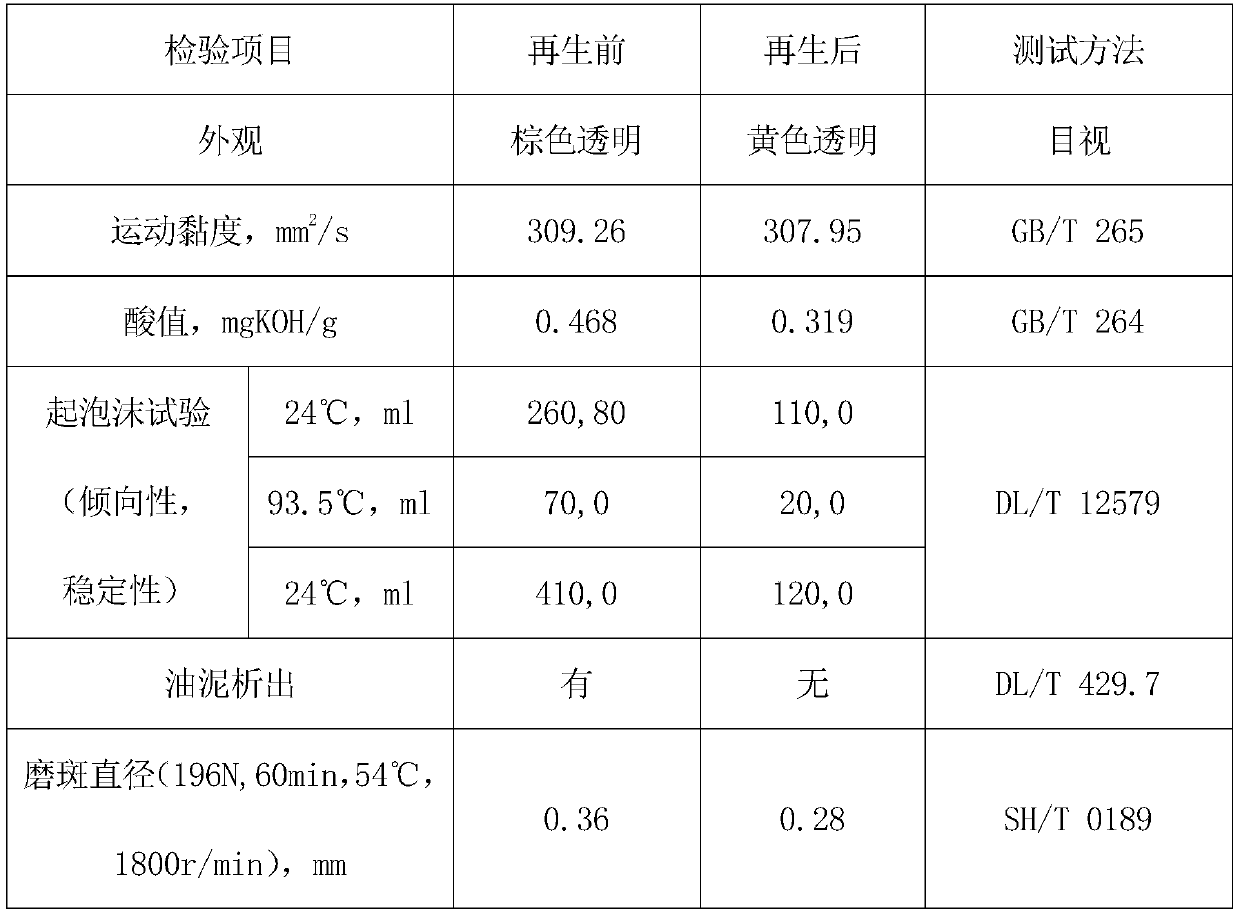

[0042] Dissolve 12g of 3-propanolamine, 5g of ammonium hydroxide and 90g of cetyltrimethylammonium bromide in 500g of distilled water, adjust the pH value to 11.5 with ammonia water and glacial acetic acid, and stir in a water bath at 75°C After 5 hours, the stirring speed was set at 800r / min, and after adding 12g of water-soluble epoxy resin emulsion and 7g of acrylic acid emulsion, continued to stir for 6 hours, then added 8.2g of powders with a particle size of about 10nm prepared by carbon nanotubes, and continued to stir for 3 hour, then a mixture of 120g white carbon black, 35g sodium silicate, 120g diethylaluminum chloride, 8g aluminum sulfate, 70g isopropyl titanate and 15g titanium sulfate was added, and the stirring speed was set to 1200r / min to continue Stir for 8 hours, cool at room temperature, place the obtained white initial gel product in a blast oven at 120°C and dry for 15 hours, wash the obtained white solid powder with absolute ethanol and distilled water th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com