Maintenance and spare part supply combined optimization method based on deterministic inventory degradation model

A degradation model and joint optimization technology, applied in data processing applications, forecasting, instruments, etc., can solve problems that affect the accuracy of joint optimization results and affect spare parts inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

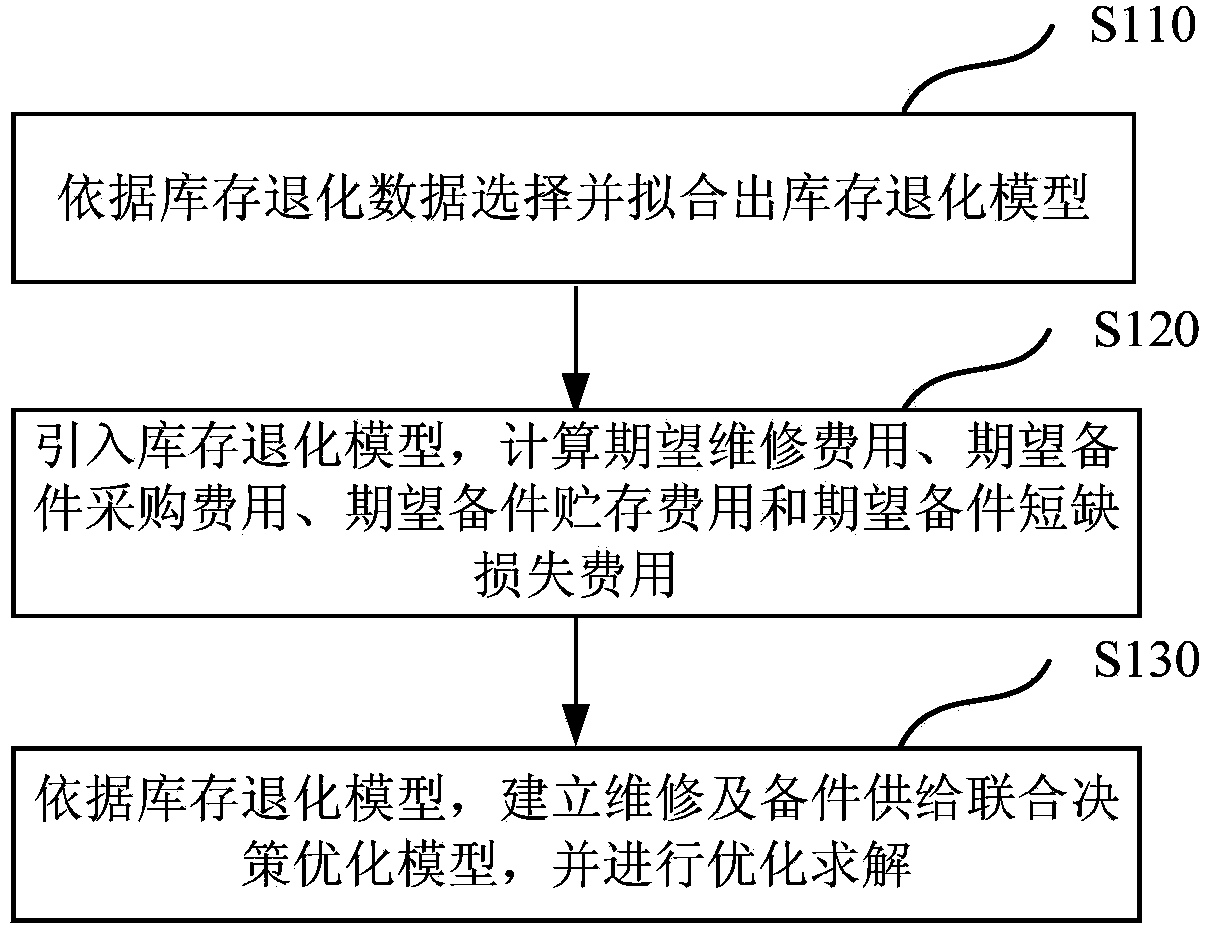

[0052] figure 1 It is a schematic flow chart of a joint optimization method for maintenance and spare parts supply based on a deterministic inventory degradation model according to an embodiment of the present invention. The following refers to figure 1 Each implementation step of the method will be described in detail.

[0053] Step S110, selecting and fitting a deterministic inventory degradation model based on the inventory degradation data.

[0054] Specifically, a deterministic inventory degradation model suitable for the joint optimization of maintenance and spare parts supply is introduced, and the deterministic inventory degradation model is fitted according to the inventory degradation data.

[0055] (1) Introduce a deterministic inventory degradation model suitable for joint optimization of maintenance and spare parts supply.

[0056] The following differential equation is used to describe the degradation of the inventory:

[0057] I'(t)=-g(t)·I(t)-d(t)(1)

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com