High-frequency motor with superconducting liquid heat dissipation and composite powder conductive wire winding stator rotor

A technology of composite powder and superconducting fluid, applied in the shape/style/structure of winding conductors, electromechanical devices, electrical components, etc., can solve the problems of large attenuation, low efficiency of wire-type transmission lines, etc., to reduce resistance and weaken the skin effect, the effect of service life increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the high-frequency motor with superconducting liquid heat dissipation and composite powder conductive wire winding the stator rotor of the present invention will be described in detail below in conjunction with the accompanying drawings.

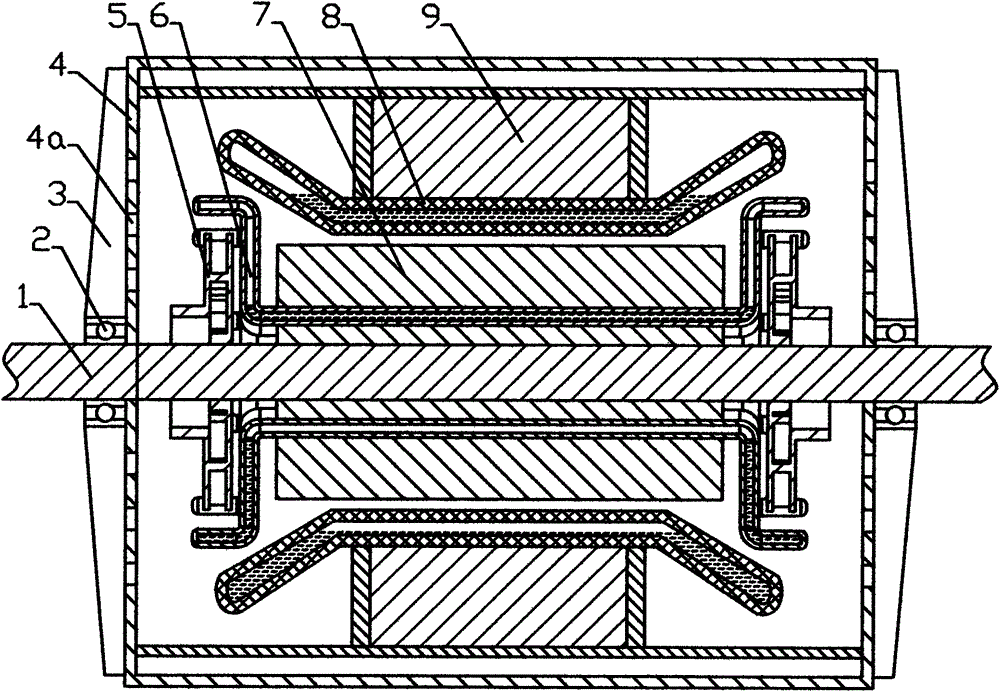

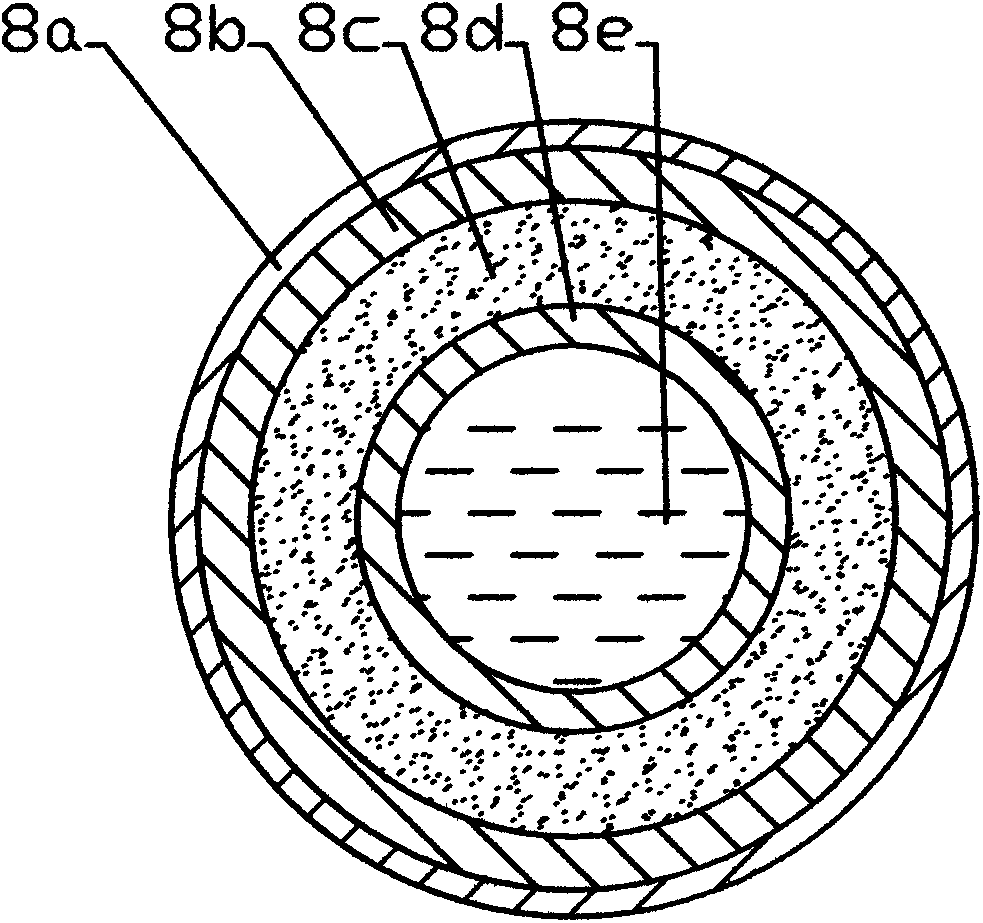

[0018] Such as figure 1 Shown is a structural diagram of a high-frequency motor with superconducting liquid heat dissipation and composite powder conductive wire winding the stator rotor of the present invention, which consists of a stator and a rotor. The stator includes a casing 4 , a stator core 9 and a stator winding 8 , and the rotor includes a rotating shaft 1 fixed in the casing 4 through a bearing bracket 3 and a bearing 2 , a rotor core 7 and a rotor winding 6 .

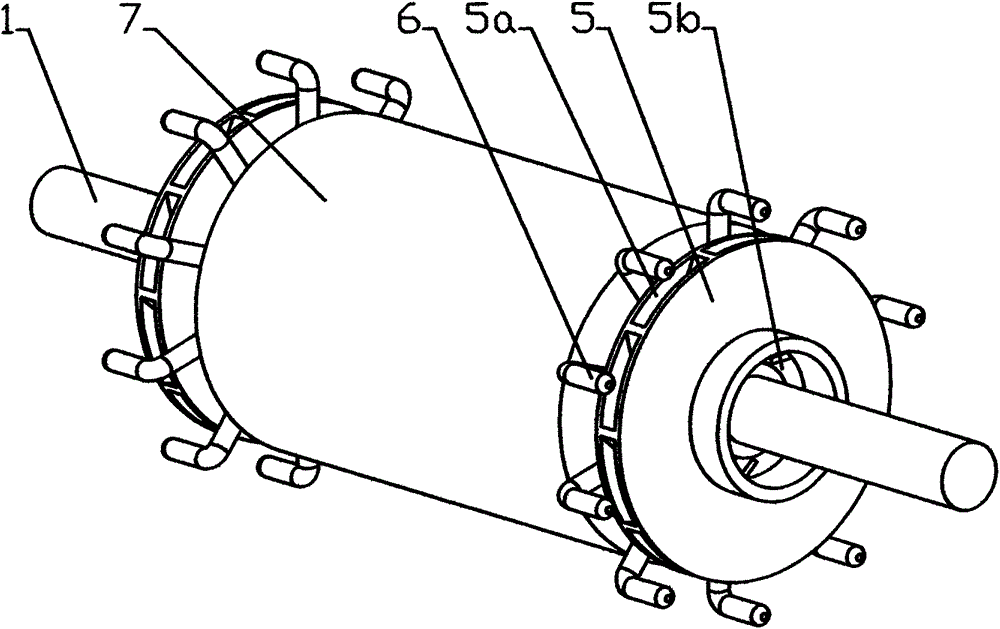

[0019] A centrifugal vane 5 is respectively adorned on the rotating shaft 1 outside the two ends of the rotor iron core 7 in the casing 4 . Such as figure 2 As shown, the central part of the outer surface of the centrifugal fan 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com